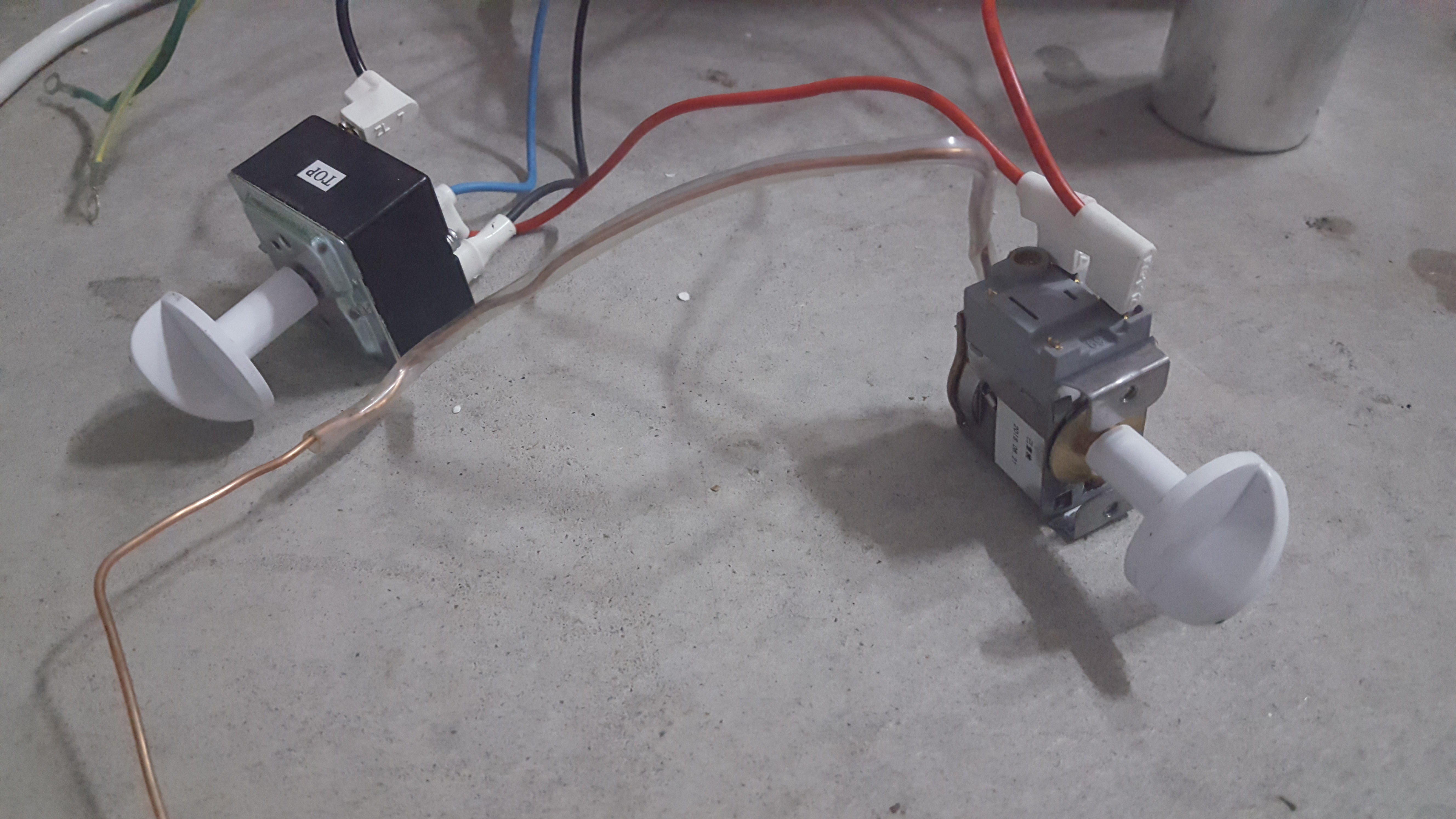

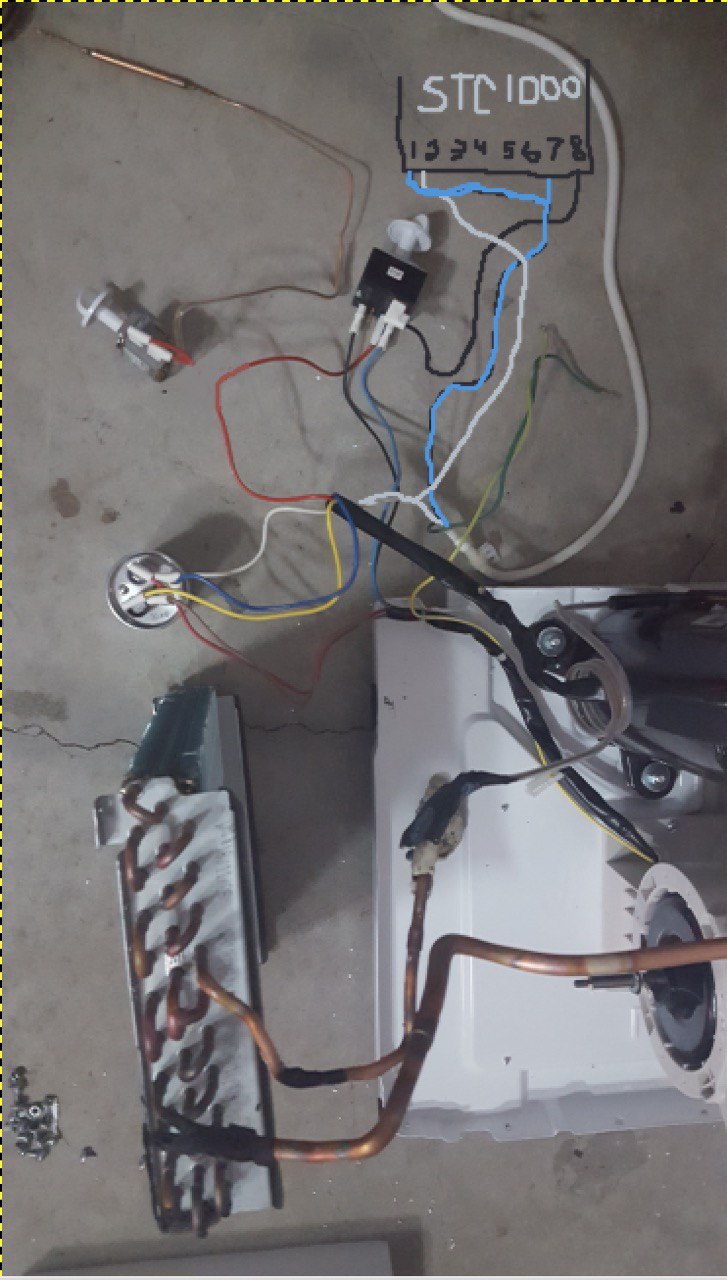

It looks like it is already hooked up. Leave capacitor wires as they are. The green grounds to chassis, and it looks like yellow/green to fan is ground too.

You could leave switches in position so always on. I'd try this first, if it works I'd leave it at that.

If you have to remove switches from circuit, below is an only semi educated guess from pictures. Wire colors are not completely standardized for internal appliance wiring, just so you know, and I am not an electrician or HVAC tech by trade, so be advised.

Again, do not unplug capacitor, you need it. Since two of the three wires from compressor are hooked to capacitor, looks like the red one to compressor may go to black power cord. If you look at your printed diagram, power cord to compressor is red or red/black to overload protector, the actual black part of cord may be under wire sheath, cant tell from here. In any case, you should leave overload protector in circuit.

You will also need to hook either blue and/or black from fan to the black on power cord.

Good luck, & for best maybe hold off on pipe while you are trying this. {;