No I have notHas anyone else tasted this off flavor? Bring some beers to the next homebrew club meeting or to the local brewery in town, see if they taste it and can identify it.

Have you had covid recently? This still screws with some folks senses.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

All my beers have this overpowering off flavor after bottling

- Thread starter Ali01

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

It was 85 percent Vienna and 15 percent crystal 10L, with Columbus for bittering my I used a very low amount maybe not even 20 abvCould you provide a recipe of the latest batch?

My first best guess with "medical," if by that you mean plastic/"band-aid" flavors, would be chlorine. Particularly if it's consistent across all your batches I'd start there.Thanks, yes pucker was not the word I was looking for, it's not really that sour, just a tiny bit, that off flavor I don't know how to describe is overpowering everything else, it's bitter and medical tasting, that's the best way I can describe it, I haven't measured that, had to left home again

In response to has anyone else tasted your beer or recent covid, you need to have someone else taste it. I've convinced myself many times over the years certain beers had an issue.No I have not

InspectorJon

Well-Known Member

Given the OP’s location (Iran), I wonder where you are sourcing your malt? Is it possible that something has been added to the malt to interfere with fermentation? Conspiracy theories abound.

RO water should not have chlorine in it, so that seems to be ruled out, unless I’m wrong about RO removing chlorine.

RO water should not have chlorine in it, so that seems to be ruled out, unless I’m wrong about RO removing chlorine.

beren

Well-Known Member

I thought ro was for salts, and a carbon filter was needed for chlorine.Given the OP’s location (Iran), I wonder where you are sourcing your malt? Is it possible that something has been added to the malt to interfere with fermentation? Conspiracy theories abound.

RO water should not have chlorine in it, so that seems to be ruled out, unless I’m wrong about RO removing chlorine.

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

jerrylotto

Well-Known Member

Reverse osmosis removes most everything, but chlorine will damage an RO membrane, so it is common to pre-filter through one or more carbon filters to remove chlorine and chloramides first.I thought ro was for salts, and a carbon filter was needed for chlorine.

jerrylotto

Well-Known Member

Chlorophenols are the origin of that taste fault, actually formed from free chlorine or mono-chloramide during fermentation. These are often used as sanitizers for municipal water sources.My first best guess with "medical," if by that you mean plastic/"band-aid" flavors, would be chlorine. Particularly if it's consistent across all your batches I'd start there.

There are people who have success with those malts , I recently realized those malts are somehow added to brew father's fermentables.Given the OP’s location (Iran), I wonder where you are sourcing your malt? Is it possible that something has been added to the malt to interfere with fermentation? Conspiracy theories abound.

RO water should not have chlorine in it, so that seems to be ruled out, unless I’m wrong about RO removing chlorine.

Here's what I'm gonna do next time, I'm gonna get some distilled water, add the essential salts and see if that fixes anything

An Ankoù

Well-Known Member

That's almost certainly chlorine or chloramine in the water supply. It can easily be corrected with half a Campden tablet or a pinch of sodium (or potassium) metabisulphite in the mash and in the sparge liquor. The chlorine compounds react with the polyphenols in the hops during the boil to give an "antiseptic" flavour which has a very low taste threshhold and it won't improve with time.My previous brew has been in the bottle for 3 months and it is still undrinkable. I gotta say that off flavor existed even before bottling, but now it's overpowering all the other flavors, so here's what I'm gonna do next time, I will use bottled water, up the og, ferment cooler, more time in the carboy, then gelatin +cold crashing, more time in the bottle. I'll see if that changes anything, but given the problem exists in all my homebrews despite the fact that I used different yeast strains, different recipes, the problem might be my water. That's what all my batches have in common

In short, the beer;s ruined. Chuck it and start again, but don't let any untreated water get into the brew before bottling.

I was taken by surprise when I moved to France. Previously I had been using water from the hot-water header tank of my old house and here I started using water directly from the mains. My beer was sometimes ok and sometimes undrinkable. I discovered that instead of simply chlorinating the supply, they "flushed" the system with chlorine from time to time to keep the pipes clean.

OP said that he uses metabisulfite.That's almost certainly chlorine or chloramine in the water supply. It can easily be corrected with half a Campden tablet or a pinch of sodium (or potassium) metabisulphite in the mash and in the sparge liquor.

An Ankoù

Well-Known Member

You're right, he did.OP said that he uses metabisulfite.

Edit:

No he didn't. Read the OP again. It caught me out, too.

I've just been reading about the use of chlorine dioxide in public supplies, especially when the water purity can be a bit suspect. No idea about the water quality of the O P, however, not whether it's removed with metabilsulphite.

The OP's idea of using bottled water, to see if it makes a difference is a good one. Best to choose a water with a low mineral content than a high one, though.

Last edited:

An Ankoù

Well-Known Member

Can you clarify what, exactly, you are adding to your water. Perhaps sending a photo of the tub.I add metabisulfate putassium powder to my RO

We use metabisulfite not ....sulfate to remove chlorine. The latter is also known as sodium or potassium dithionate and is not the same thing at all.

Last edited:

I bought a 15 liters of deionized 3 stage distilled water to experiment with, if that works, then that metabisulphite powder of me is fakeYou're right, he did.

Edit:

No he didn't. Read the OP again. It caught me out, too.

I've just been reading about the use of chlorine dioxide in public supplies, especially when the water purity can be a bit suspect. No idea about the water quality of the O P, however, not whether it's removed with metabilsulphite.

The OP's idea of using bottled water, to see if it makes a difference is a good one. Best to choose a water with a low mineral content than a high one, though.

O

I know, the store said it was metabisulfate putassium powder, it's a white powderCan you clarify what, exactly, you are adding to your water. Perhaps sending a photo of the tub.

We use metabisulfite not ....sulfate to remove chlorine. The latter is also known as sodium or potassium dithionate and is not the same thing at all.

An Ankoù

Well-Known Member

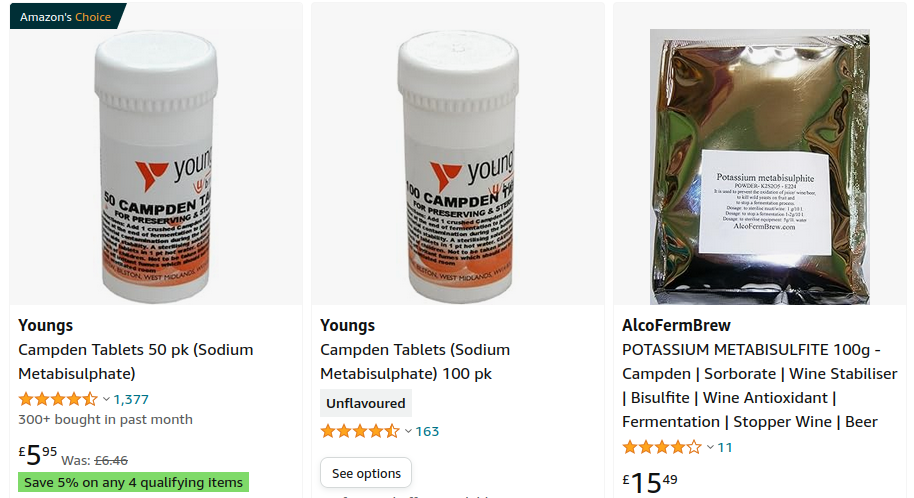

MetabisulfIte is not the same as metabsulfAte. The stuff you need is also known as Campden powder and it often comes in the form of tablets.O

I know, the store said it was metabisulfate putassium powder, it's a white powder

As for the powder the store sold you, try sniffing it CAUTIOUSLY. It should have a sharp, choking odour unless it's very dry. If no smell, try dissolving a teaspoonful in a half a cup of cold water and add a bit of lemon juice or any other acid. If you don;t get the sharp, choking smell, it's not metabisulfite. You could also go back to the store and explain the situation and ask him to show you the label of the stuff he sold you. (probably best not to mention brewing. Aren't they a bit funny about that in Iran?)

It's worth persisting as it's a really cheap and effective fix. Any of the first 3 products, here, will remove the chlorine:

Of course if you get the same problem with the de-ionised water, then we'll need to look elsewhere for a solution.

Last edited:

DuncB

Well-Known Member

My pot of Metabisulphite I only have to open and then wave my hand over the top in my general direction and it's noxious for sure.

I notice that you say in your first post that you use RO water, so chlorine or chloramine won't be an issue.

You do say that the " it tasted fine before bottling, fruity, sweet,"

This could be oxidation already starting, do you open ferment and when do you transfer or know when to transfer to bottles.

Could you give us an indication of your ingredients, recipe and a little more about the ferment process please.

What would be your final gravity reading?

How do you sanitise your equipment and bottling gear?

I notice that you say in your first post that you use RO water, so chlorine or chloramine won't be an issue.

You do say that the " it tasted fine before bottling, fruity, sweet,"

This could be oxidation already starting, do you open ferment and when do you transfer or know when to transfer to bottles.

Could you give us an indication of your ingredients, recipe and a little more about the ferment process please.

What would be your final gravity reading?

How do you sanitise your equipment and bottling gear?

O

I know, the store said it was metabisulfate putassium powder

Now I'm thinking the off flavor might've been there all along cause I've heard that carbonation intensifies flavorMy pot of Metabisulphite I only have to open and then wave my hand over the top in my general direction and it's noxious for sure.

I notice that you say in your first post that you use RO water, so chlorine or chloramine won't be an issue.

You do say that the " it tasted fine before bottling, fruity, sweet,"

This could be oxidation already starting, do you open ferment and when do you transfer or know when to transfer to bottles.

Could you give us an indication of your ingredients, recipe and a little more about the ferment process please.

What would be your final gravity reading?

How do you sanitise your equipment and bottling gear?

I'm brewing a new one using distilled water and salts today, it's a small 8.5L batch for experiment

An Ankoù

Well-Known Member

You need to give us more details. You say in post #1 that you use one of three Fermentis dried yeasts. There's no need to make a starter with these yeasts- certainly not in an 8,5 litre batch!.Just one more thing, do I need to let the starter finish before adding it to the wort? Or can I just add it after one day of going, sacrificing more yeast cells to be produced

Tell us how you make your starter.

In any case, just chuck it in.

Sorry I'm late...

This problem sounds exactly like chlorophenol, and it makes sense if trying to neutralize chlorine using sulfate instead of sulfite.

Get some new metabisulfite powder or Campden tablets, and see if that fixes the whole problem.

This problem sounds exactly like chlorophenol, and it makes sense if trying to neutralize chlorine using sulfate instead of sulfite.

Get some new metabisulfite powder or Campden tablets, and see if that fixes the whole problem.

Where do you get the RO water? As has been said, RO water shouldn't contain any chlorine (because chlorine wrecks RO membranes so RO systems are designed to remove it first). Also sounds like your metabisulfate or sulfite wasn't in a labeled package, so the problem could be sulfate instead of sulfite, or it could be that they sold you cornstarch.

I made a starter with the harvested yeast from the one of my older batches that was a success, I guess my RO system was better at that time, I think I haven't changed the filters in a long time and that could be the issue with chlorineYou need to give us more details. You say in post #1 that you use one of three Fermentis dried yeasts. There's no need to make a starter with these yeasts- certainly not in an 8,5 litre batch!.

Tell us how you make your starter.

In any case, just chuck it in.

How old is that saved slurry?Just one more thing, do I need to let the starter finish before adding it to the wort? Or can I just add it after one day of going, sacrificing more yeast cells to be produced

Been refrigerated all the time?

How much slurry did you put in the starter? Any idea how many cells were in there?

What volume/gravity is the starter, approximately?

A 1-day starter would be considered a "vitality starter" rejuvenating the cells, but not much, if any growth.

It takes 2-3 days to see ample growth. With older or less healthy yeast it may take 3-7 days to get any appreciable amount.

Is this starter on a stir plate at around 20-30°C?

Yes it was metabisulfite actually, just a typo, sorry, the label says campden in farsi but it's not commercially packaged, it's a repack, yes they areMetabisulfIte is not the same as metabsulfAte. The stuff you need is also known as Campden powder and it often comes in the form of tablets.

As for the powder the store sold you, try sniffing it CAUTIOUSLY. It should have a sharp, choking odour unless it's very dry. If no smell, try dissolving a teaspoonful in a half a cup of cold water and add a bit of lemon juice or any other acid. If you don;t get the sharp, choking smell, it's not metabisulfite. You could also go back to the store and explain the situation and ask him to show you the label of the stuff he sold you. (probably best not to mention brewing. Aren't they a bit funny about that in Iran?)

It's worth persisting as it's a really cheap and effective fix. Any of the first 3 products, here, will remove the chlorine:

View attachment 838154

Of course if you get the same problem with the de-ionised water, then we'll need to look elsewhere for a solution.

We all run into this from time to time. Beer tastes good at bottlng, tastes phenolic after 2 weeks in the bottle. I’ve had this ongoing most of last year. Phenolic bottles after a couple weeks, but anything I keg is fine even after months. I haven’t figured it out, but it has to be something in the bottling line. If keg beers are fine then it can’t be siphon cane/tubing either, I’m using the same one.

I’ve cleaned everything with pbw, taken bottle bucket and bottle faucet apart, scrubbed, soaked everything in pbw, then star san, replaced hoses. Been through 3 bottling wands. Boiled sugar, stirred in with sanitized spoon. Sanitized bottle bucket with star san. I’ve soaked bottles in bleach, followed by pbw overnight, scrubbed with bottle brush. visually inspected clean, throw away ones that won’t. I’ve tried star san on some bottles, iodophor on others in an avinator right before filling. I sanitize caps in star san. Same results - kegs good, bottles suck. I’ve even tried priming with dme instead of corn sugar to see if that made a difference. I’m still trying to figure it out.

I’ve cleaned everything with pbw, taken bottle bucket and bottle faucet apart, scrubbed, soaked everything in pbw, then star san, replaced hoses. Been through 3 bottling wands. Boiled sugar, stirred in with sanitized spoon. Sanitized bottle bucket with star san. I’ve soaked bottles in bleach, followed by pbw overnight, scrubbed with bottle brush. visually inspected clean, throw away ones that won’t. I’ve tried star san on some bottles, iodophor on others in an avinator right before filling. I sanitize caps in star san. Same results - kegs good, bottles suck. I’ve even tried priming with dme instead of corn sugar to see if that made a difference. I’m still trying to figure it out.

Last edited:

Shoot... I wanted to mention but I forgot until now.... what kind of hoses are you using for transferring wort? Some hoses, as well as some o-rings and gaskets, and certain plastics, will give off phenolic characteristics as well.

It's a food grade silicon hoseShoot... I wanted to mention but I forgot until now.... what kind of hoses are you using for transferring wort? Some hoses, as well as some o-rings and gaskets, and certain plastics, will give off phenolic characteristics as well.

That's just about my caseWe all run into this from time to time. Beer tastes good at bottlng, tastes phenolic after 2 weeks in the bottle. I’ve had this ongoing most of last year. Phenolic bottles after a couple weeks, but anything I keg is fine even after months. I haven’t figured it out, but it has to be something in the bottling line. If keg beers are fine then it can’t be siphon cane/tubing either, I’m using the same one.

I’ve cleaned everything with pbw, taken bottle bucket and bottle faucet apart, scrubbed, soaked everything in pbw, then star san, replaced hoses. Been through 3 bottling wands. Boiled sugar, stirred in with sanitized spoon. Sanitized bottle bucket with star san. I’ve soaked bottles in bleach, followed by pbw overnight, scrubbed with bottle brush. visually inspected clean, throw away ones that won’t. I’ve tried star san on some bottles, iodophor on others in an avinator right before filling. I sanitize caps in star san. Same results - kegs good, bottles suck. I’ve even tried priming with dme instead of corn sugar to see if that made a difference. I’m still trying to figure it out.

Similar threads

- Replies

- 13

- Views

- 762

- Replies

- 41

- Views

- 1K