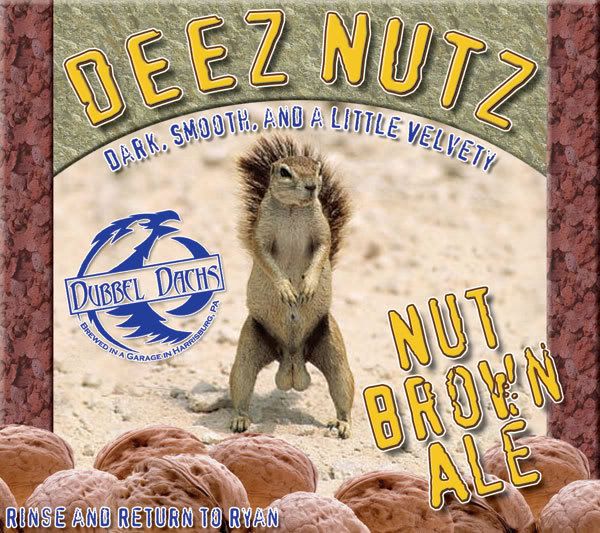

Sorry for my slow reply ... looks like a great beer you have there.

Yes, you are correct in that a thinner mash versus a thicker one (ALL other things being equal) should produce a more fermentable wort. From Fix* (via DeClerk): "It has been known that thicker mashes favor proteoletic activity whereas thinner mashes favor carbohydrase action because of the restraining influence [high] sugar concentrations have on alpha and beta amylase activity."

In other terms, if it's too thick, the enzymes will be prohibited from doing a thorough job of breaking sugars down into fermentables.

I would say that mash temperature plays a MUCH larger role in producing a more or less fermentable wort so, if your process is working for you and you are hitting the mash temps you have designed into your recipe (higher = less fermentable) then the thickness is probably of minor concern. It is, however, one more tool in your brewer's toolbox.

Again, great work.

*Fix, George : Principles of Brewing Science (2nd ed) - 1999

Yes, you are correct in that a thinner mash versus a thicker one (ALL other things being equal) should produce a more fermentable wort. From Fix* (via DeClerk): "It has been known that thicker mashes favor proteoletic activity whereas thinner mashes favor carbohydrase action because of the restraining influence [high] sugar concentrations have on alpha and beta amylase activity."

In other terms, if it's too thick, the enzymes will be prohibited from doing a thorough job of breaking sugars down into fermentables.

I would say that mash temperature plays a MUCH larger role in producing a more or less fermentable wort so, if your process is working for you and you are hitting the mash temps you have designed into your recipe (higher = less fermentable) then the thickness is probably of minor concern. It is, however, one more tool in your brewer's toolbox.

Again, great work.

*Fix, George : Principles of Brewing Science (2nd ed) - 1999

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)