meridianflyer

Member

- Joined

- Dec 28, 2012

- Messages

- 6

- Reaction score

- 0

Ok, stupid question, finishing up my keezer build and getting ready to install the fan. Which way do I want the airflow? I think it needs to blow towards the lid, right?

Yes, think convection currents. Cold air sinks, hot air rises. I have mine blowing from bottom to top.Ok, stupid question, finishing up my keezer build and getting ready to install the fan. Which way do I want the airflow? I think it needs to blow towards the lid, right?

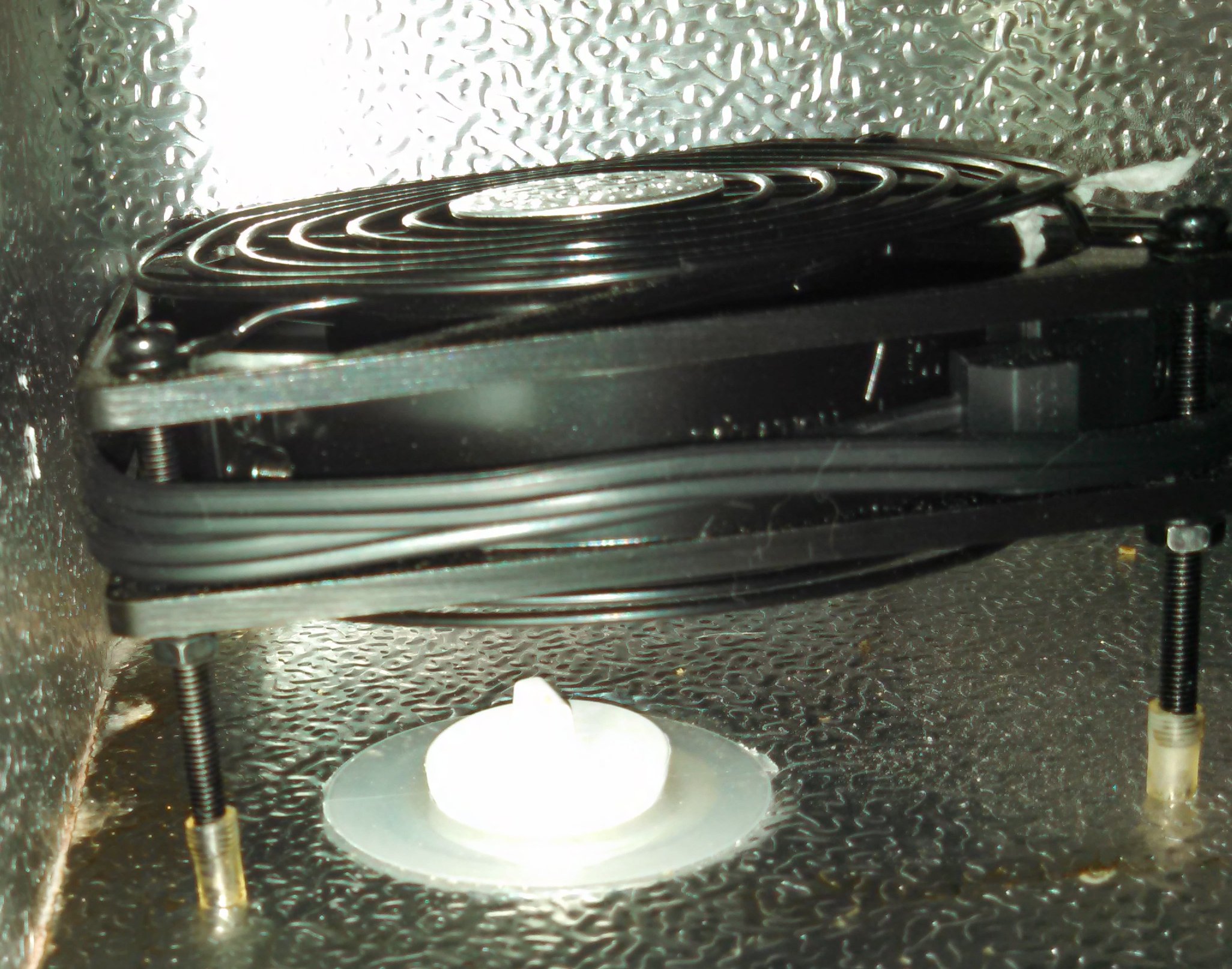

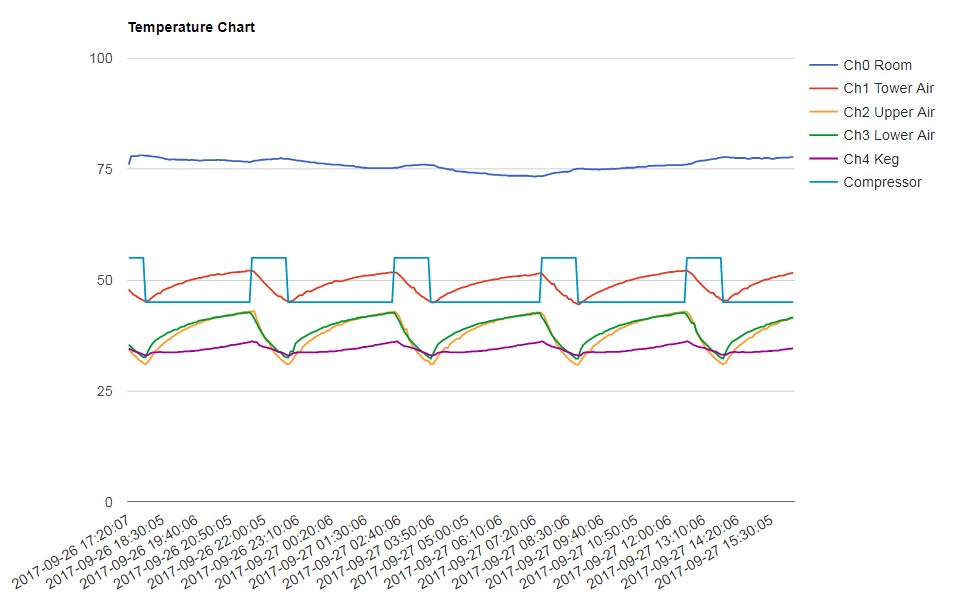

I like the chart! Looks like your tower air is quite a bit warmer. Does this pose any foaming issues?It may depend on the keg configuration but I have a 120mm 12vdc fan running at 9vdc perched upon the keezer hump firing along the long dimension between two rows of three kegs. This is an example plot from my temperature monitor showing there's not much temperature difference between the top and bottom of the interior space...

View attachment 643846

Cheers!