Garage12brewing

Well-Known Member

Hi guys,

Last night I brewed a Double IPA and after I transfered the wort in the fermenter I ended up with at least 8-10L of hops mixed with the wort. ( I brew 45L batch )

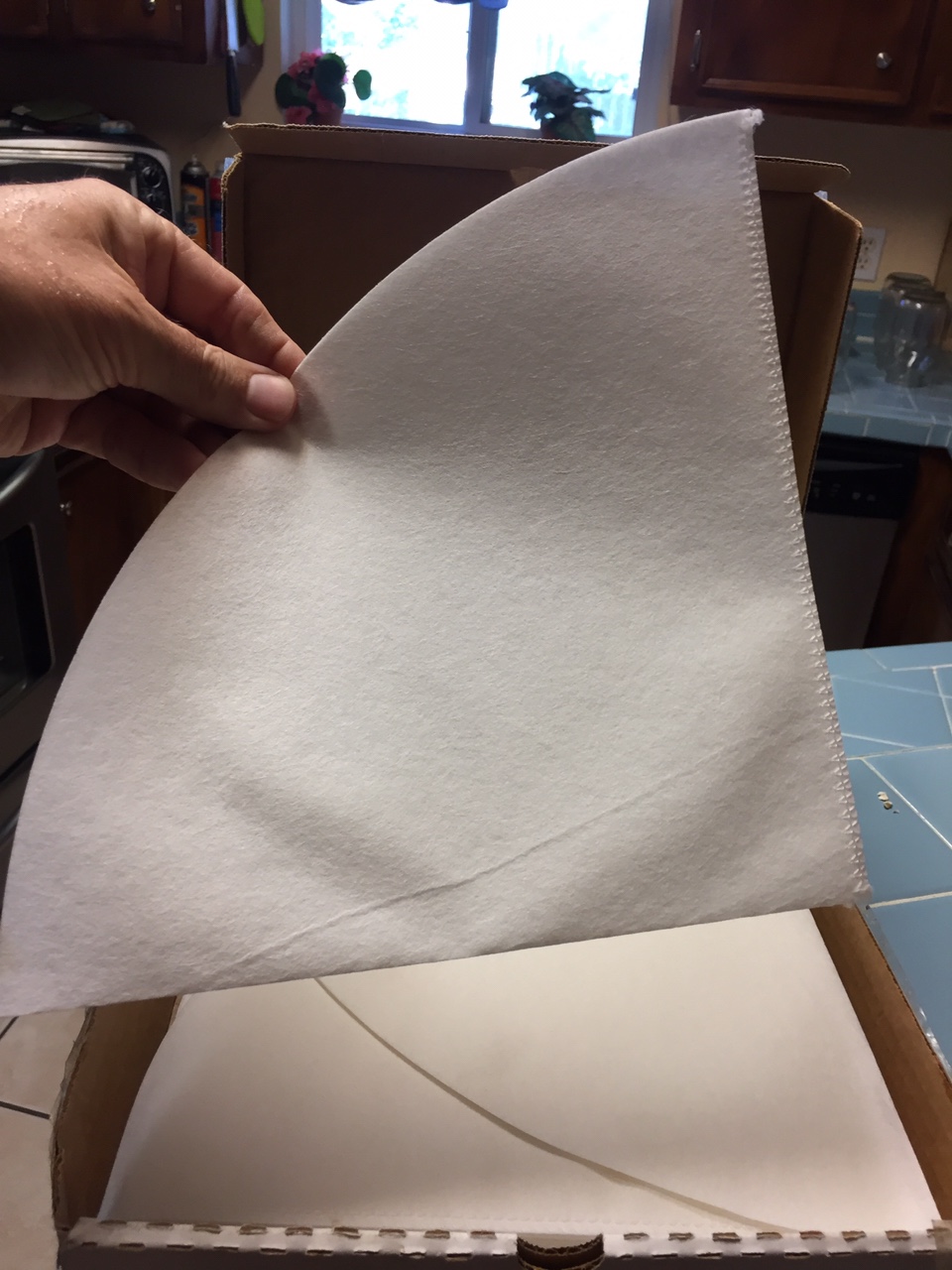

I would like to know if there is any technique to filter the last 5-10L wort after the transfer tothe fermenter to get the most beer possible ! Especialy when brewing beer with lots of hops...

Its not the first time that it is happening but I want to to figure out a way to improve that.

Thanks a lot !

Last night I brewed a Double IPA and after I transfered the wort in the fermenter I ended up with at least 8-10L of hops mixed with the wort. ( I brew 45L batch )

I would like to know if there is any technique to filter the last 5-10L wort after the transfer tothe fermenter to get the most beer possible ! Especialy when brewing beer with lots of hops...

Its not the first time that it is happening but I want to to figure out a way to improve that.

Thanks a lot !

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)