Gonefishing

Someday I'll stop procrastinating

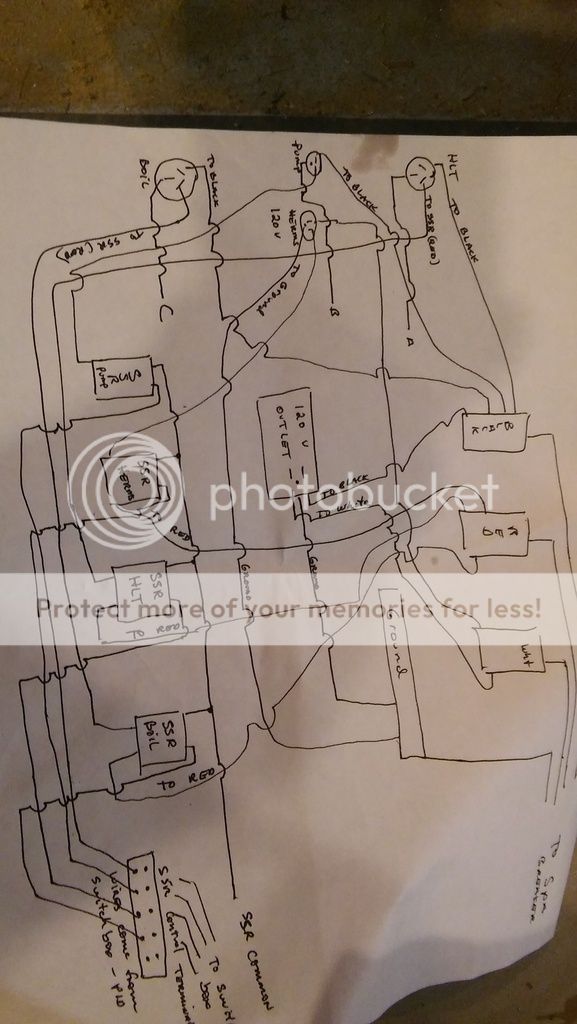

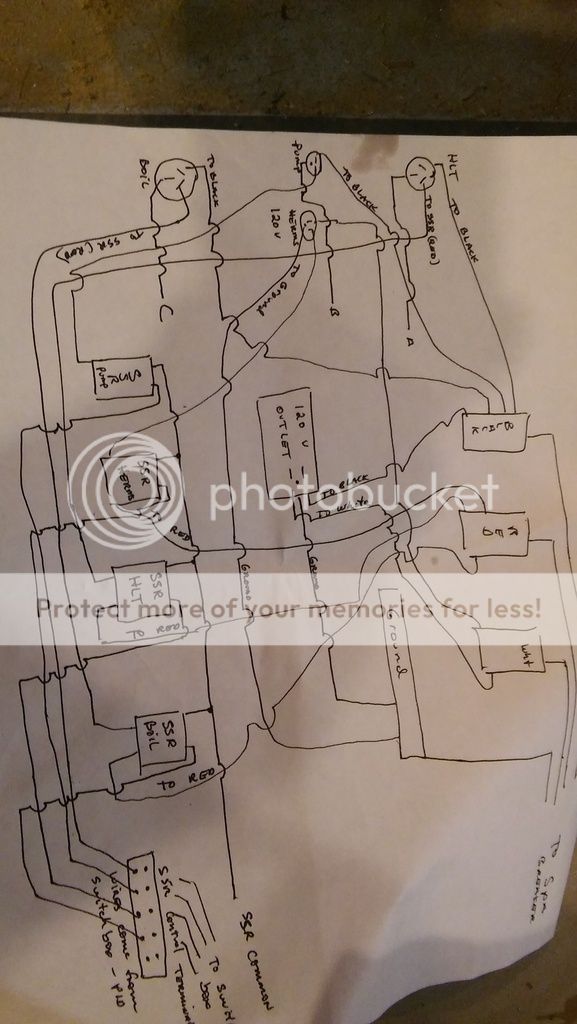

This is the wiring diagram I came up with for the electric box for my brewery. It doesn't show the PID and controls for the SSRs because all that is in a separate box.

I am not sure whether to connect wires A, B, and C to N or ground...can someone please help me out with that?

I am not sure whether to connect wires A, B, and C to N or ground...can someone please help me out with that?

Last edited by a moderator: