GrogNerd

mean old man

by "monitor" the temps, I thought you meant just that: reading what the temperature is at any specific time

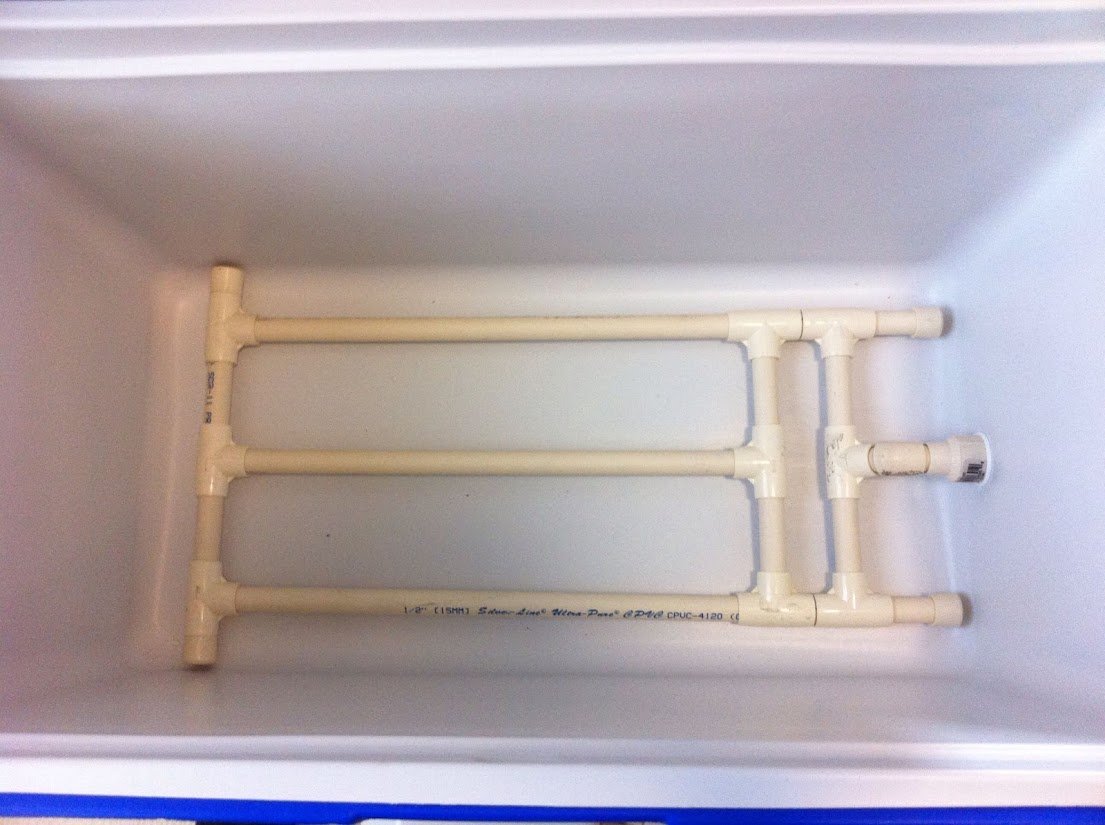

RIMS is for recirculating mash, which would not really be necessary in a cooler. that's what the cooler is for: maintaining temperature during the mash. mine lost 3° first time I used it, so the next time I covered the mash with aluminum foil and only lost 1°.

as for sparge, would only need to heat the water to mash out temp, keep it in a HLT (possibly another cooler) and slowly let it drain for a continuous sparge, circulating the vorlauf as needed, then letting the runnings drain

RIMS is for recirculating mash, which would not really be necessary in a cooler. that's what the cooler is for: maintaining temperature during the mash. mine lost 3° first time I used it, so the next time I covered the mash with aluminum foil and only lost 1°.

as for sparge, would only need to heat the water to mash out temp, keep it in a HLT (possibly another cooler) and slowly let it drain for a continuous sparge, circulating the vorlauf as needed, then letting the runnings drain

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)