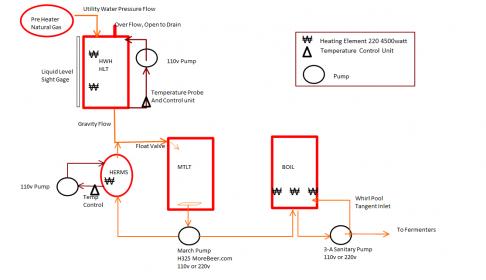

HLT/HWH Control unit;

Each tank control unit will be independent from each other.

This will keep the system modular. I expect a lot of changes over the next year or so.

The HLT is a 50 gallon standard Hot water heater. I will remove the built in thermostats.

I will also make sure the system is 'open' so as not to be able to build up pressure.

And it will still have a pressure release valve built in.

It is filled manually by turning on a ball valve for filling with preheated water.

There is an overflow pipe to a near by drain. (Figured this out the hard way.)

Water is circulated from the bottom to the top by a March pump. This prevents temperature variations.

The Sensor is fitted into the recirculation pipe.

A sight glass is attached to know the fill level and to measure the amount being infused into the mash.

I will have this higher than the MLT so I can gravity sparge. But it could be pumped easily if I want to lower it.

I have allreay made a 20 gallon unit like this and used a purchased controller.

Here is what is needed from the control unit:

1) Power feed In; 220v Single phase

2) Control unit power on/off at incoming point. Lighted push button to 220 relay.

Auber SW1 Red and Contactor, 2 pole 40 A, 240V coil CN-PBC402-240V

3) Single SYL-2352 PID temperature controller

Pt100 RTD Sensor

4) Single SSR to single 220v output to power 1 or 2 4500watt elements

Auber 40 A SSR RS1A40D40

5) Water level protection switch.

Elements can not come on if water is below minimum level.

http://www.mcmaster.com/#liquid-level-switches/=e7tysr

and

http://www.mcmaster.com/#liquid-level-switches/=e7u3yj

6) Indicator light when power is being suppied to heating elements

7) Over Temp Alarm

Flashing Buzzer Auber FLBuz

7) 2 Switched pump controls. 1 for Recirculation , 1 for future use.

110v Outlets

Auber SW1 Blue

What would be the advantage of a 4 wire system vs 3 wire?

Can you indicate the wire gauges needed inside the control panel?

P-J if you can design my control panels, I will upgrade your account to LifeTime Supporter. Or whatever else I can do for you.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)