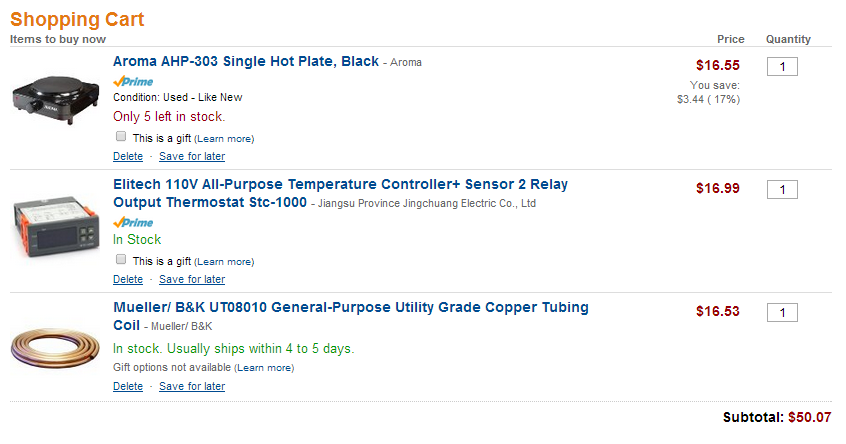

I will be documenting my new HERMS system build here. First off, I'm a cheapskate, so this is an extremely budget HERMS build. My plan is that for 50$ or slightly more depending on what I have lying around the house I can add a HERMS to my build. The 50$ price tag assumes you have a pump. But the price includes:

Heating

Coil

Automation

If you dont have a smaller pot lying around go to your local thrift store or pick a new one up at Walmart for 7$

From the 4 Items in the images I'm assuming most of you can get an idea of the final product. I will be making this and testing it soon, items are already ordered. If I'm right this will be a super inexpensive way to add HERMS to your brewery at a cost cheaper than most PIDs so we will see.

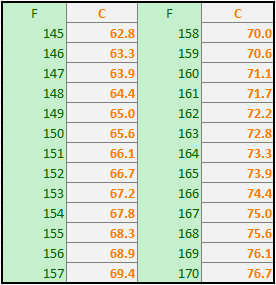

If your a dumb american like me and have to use F instead of C for everything this could come in handy to tape to the pot as well.

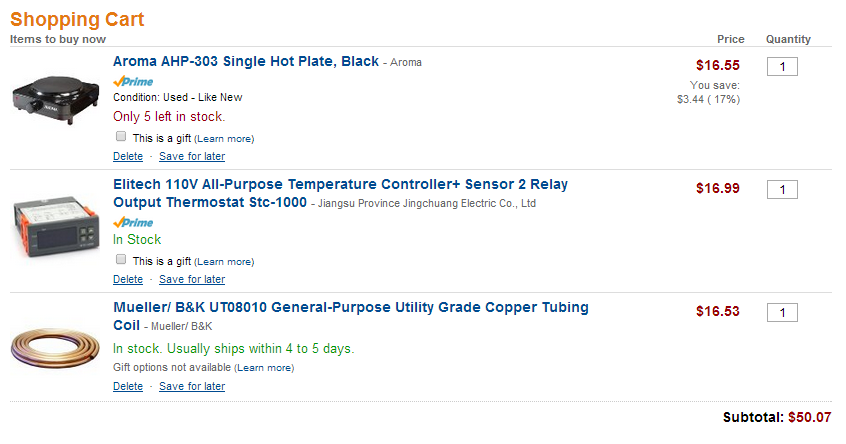

Heating

Coil

Automation

If you dont have a smaller pot lying around go to your local thrift store or pick a new one up at Walmart for 7$

From the 4 Items in the images I'm assuming most of you can get an idea of the final product. I will be making this and testing it soon, items are already ordered. If I'm right this will be a super inexpensive way to add HERMS to your brewery at a cost cheaper than most PIDs so we will see.

If your a dumb american like me and have to use F instead of C for everything this could come in handy to tape to the pot as well.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)