This Is The Final Revision. (I hope)

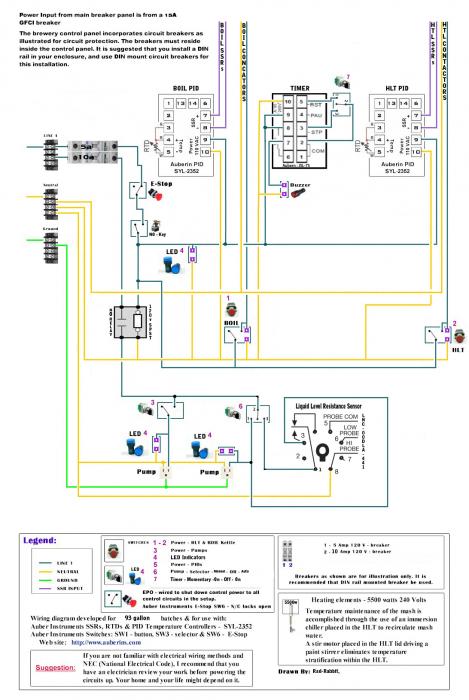

The controls panel now has a master key start and a master power indicator.

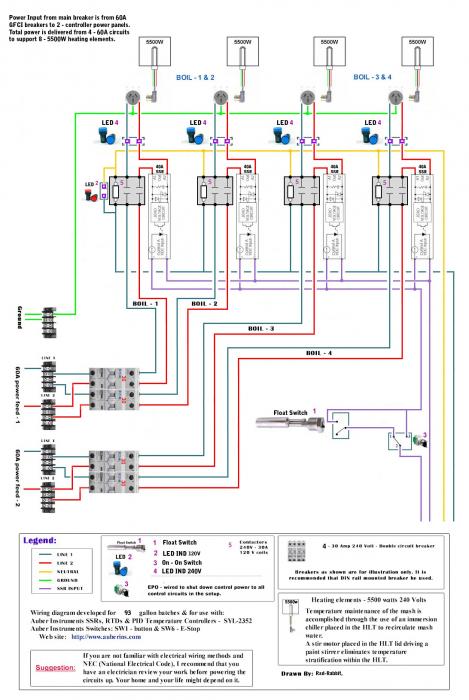

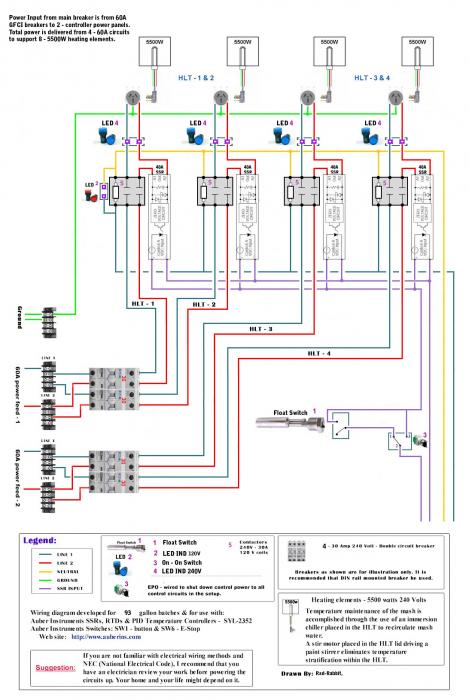

Both Power Panels have been completely redesigned from the ground up.

SSR's are now after the contactors. You can now push the (Boil or HLT) buttons and it will open both the contactors and the SSRs while not interfering with the display of PIDs and the timer on the Controls panel.

The timer now has momentary switch for STOP and RESET.

Each element has it's own 240V indicator to monitor that they are receiving power and quickly diagnose if there is a problem individually.

The float switch has a bypass switch.

Each pump has an indicator and one pump has an automated mode for liquid level resistance to use in vorlauf and lauter, and pump over to the boil kettle without pumping directly out of the MLT.

I can think of no other design inclusions that I would want or safety issues to be concerned with.

I'd like to cash-out on the design portion of the panels. I still have to finish the AutoCad and Solidworks drawings of the tanks, plumbing and platform. OH YES, I will have a platform!

Now with a little help (or a lot) putting together the parts list, I see no reason why I couldn't start putting orders in by Friday or Monday at the latest!!

Continuous thanks to all involved!

(I hope)... Well I hoped but there seems to be one more correction left.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I'd like to cash-out on the design portion of the panels. I still have to finish the AutoCad and Solidworks drawings of the tanks, plumbing and platform. OH YES, I will have a platform!

I'd like to cash-out on the design portion of the panels. I still have to finish the AutoCad and Solidworks drawings of the tanks, plumbing and platform. OH YES, I will have a platform!