You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3-phase split load design

- Thread starter podz

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Glad you found a way to make some progress. Hope you are healing up well.

Preparing for phase two: yesterday bought 100 meters (325 feet) of lamp cable and 200 meters (650 feet) of socket cable. That should be enough for SWMBO to do the rest of the cabling (our entire installation is surface-mounted).

- Joined

- Apr 11, 2013

- Messages

- 376

- Reaction score

- 61

Good luck with your project Podz.

Just wanted to chime in as to why panel load balancing is... and isn't important for a utility.

In the USA most home power has two phases. Technically though it is only one phase as far as the utility is concerned, which is split in the middle to produce two phases via the transformer on the nearest pole outside your house. The utility doesn't give two hoots about panel balancing in this case because your home is only pulling power from one of the utilities three phases.

It is good practice, as an electrician though, to balance a panel between its available phases because you never know when the home owner is going to decide they want to add another 50 amp breaker in their panel for home brewing or other purposes. In that case if the panel is unbalanced, that could cause the main breaker to trip unnecessarily even though your total power use is below its tripping value.

The phase balance is more important, from a utilities perspective, in buildings that have multiple phases. The reason why is much like what I just stated above.

Lets say there are 50 buildings that have three a three phase service, but for some reason or another out of those 50 the L1 or A phase is loaded more than the other two. Maybe by 20%. In what a utility would consider a peak demand time, the circuit that runs out from a substation to those 50 buildings will be considerably loaded, maybe to 90%. That A phase though. Its drawing 20% more, so the breaker back at the substation see excessive current over a period of time, and trips. Now all 50 buildings are out of power.

If all the panels were balanced then all three phases would have been below max capacity. Now imagine a circuit that is supplying 100 thousand buildings. Same thing.

I may have been a little wordy, but that is the reason why utilities care.

Just wanted to chime in as to why panel load balancing is... and isn't important for a utility.

In the USA most home power has two phases. Technically though it is only one phase as far as the utility is concerned, which is split in the middle to produce two phases via the transformer on the nearest pole outside your house. The utility doesn't give two hoots about panel balancing in this case because your home is only pulling power from one of the utilities three phases.

It is good practice, as an electrician though, to balance a panel between its available phases because you never know when the home owner is going to decide they want to add another 50 amp breaker in their panel for home brewing or other purposes. In that case if the panel is unbalanced, that could cause the main breaker to trip unnecessarily even though your total power use is below its tripping value.

The phase balance is more important, from a utilities perspective, in buildings that have multiple phases. The reason why is much like what I just stated above.

Lets say there are 50 buildings that have three a three phase service, but for some reason or another out of those 50 the L1 or A phase is loaded more than the other two. Maybe by 20%. In what a utility would consider a peak demand time, the circuit that runs out from a substation to those 50 buildings will be considerably loaded, maybe to 90%. That A phase though. Its drawing 20% more, so the breaker back at the substation see excessive current over a period of time, and trips. Now all 50 buildings are out of power.

If all the panels were balanced then all three phases would have been below max capacity. Now imagine a circuit that is supplying 100 thousand buildings. Same thing.

I may have been a little wordy, but that is the reason why utilities care.

Just wanted to chime in as to why panel load balancing is... and isn't important for a utility.

The reason utilities are concerned was discussed in #15. In case you didn't see it:

More seriously though and without getting too technical (I hope) a three phase system can be described by three currents: positive sequence, negative sequence and 0 sequence. The last is the neutral current. If it is appreciable the system can launch 'strays' which can, for example, shock cows connected to milking machines. If the three loads (phases A, B and C) are balanced 0 sequence current is 0. That's a good thing. Negative sequence current rotates in the opposite direction of the supplied voltages. IOW if the utility supplies the sequence A,B,C,A... negative sequence current is C,B,A,C.... This results in a field component in connected machines (motors, generators) running in the opposite directions of those machines' rotors which results in double frequency eddy currents and excess heating. Not a good thing. If the loads on phases A, B and C are equal the negative sequence current is 0.

The reason the home owner should care about panel balance is that if his loads are unbalanced badly enough neutral voltage can depart from ground voltage. Also I'm sure code requires it. This assumes you are on a biphase system. If you are a 3 phase customer you don't want imbalance because you don't want negative sequence currents over heating your motors any more than anyone else does.

The utilities have lots of ways of dealing with imbalance when it occurs. If, for example, there is a single phase to ground fault in a distribution system the protective fuses/cutouts/breakers for that phase open which removes that phase from the system although the other two phases may still be hot. This would happen, for example, if a tree branch falls across the primary line in my neighborhood taking it off line. If my neighborhood is on phase A obviously the relative loads on phase B and C go up. There is neutral sequence current and there is negative sequence current in those cases and the utility doesn't like that, of course, so they try to clear the fault. Their fault management strategies depend on monitoring of those currents.

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

- Joined

- Apr 11, 2013

- Messages

- 376

- Reaction score

- 61

I'm sorry ajdelange I missed your post for some reason. I did have a few last night though so that is probably why.

I agree with you having an event where one of the phases had low voltage it would stress motors and the like. I have never seen that happen as of yet though. I have seen motors burn up from locked rotors and such, and I have seen 3 phase motors lose one phase and cause the overload protection to operate. I have never seen a poorly balanced system cause an undervoltage to such a degree though, unless it is in the event of a single line to ground like you stated. Granted these are probably lessons the electric industry has learned over time.

Maybe I haven't seen this stuff because I have learned from good electricians, and we fix the problems that others leave.

Either way thanks for the explanation.

Podz. I will not hijack your thread so this is the last post I will put that is not related to your project.

I agree with you having an event where one of the phases had low voltage it would stress motors and the like. I have never seen that happen as of yet though. I have seen motors burn up from locked rotors and such, and I have seen 3 phase motors lose one phase and cause the overload protection to operate. I have never seen a poorly balanced system cause an undervoltage to such a degree though, unless it is in the event of a single line to ground like you stated. Granted these are probably lessons the electric industry has learned over time.

Maybe I haven't seen this stuff because I have learned from good electricians, and we fix the problems that others leave.

Either way thanks for the explanation.

Podz. I will not hijack your thread so this is the last post I will put that is not related to your project.

I agree with you having an event where one of the phases had low voltage it would stress motors and the like. I have never seen that happen as of yet though.

Imbalanced loads result in negative sequence voltages which result in negative sequence currents which cause motors and generators to heat more than they would otherwise. If the plant manager's secretary plugs in a single phase electric heater in her office that's not likely to cause sufficient negative sequence voltage to burn out all the motors in the plant or even enough to cause a measurable temperature rise. But remember that we got started looking into this from the POV of the utility when OP posted that his utility micromanages the balance of each customer. The utility definitely wants to present its generators with balanced loads because when their machines are running at 105% rating (summer, peak load) they don't have any margin. So they monitor balance throughout the network. If a substation finds that one distribution phase is drawing more current on average than another I would guess that the utility (talking US now) would reassign neighborhoods to different phases. For example, if the local substation found Phase A persistently relatively overloaded they might move my neighborhood (and some others) to Phase B - only have to move/replace one wire to do that.

I have seen motors burn up from locked rotors and such, and I have seen 3 phase motors lose one phase and cause the overload protection to operate. I have never seen a poorly balanced system cause an undervoltage to such a degree though, unless it is in the event of a single line to ground like you stated.

Maybe I haven't seen this stuff because I have learned from good electricians, and we fix the problems that others leave.

No engineer will design a plant that presents an imbalanced load to the utility (because the utility will be on him if he does). Thus imbalances, within a plant, are small (the secretary's heater, the fact that one department leaves its lights on when another doesn't) except in the case of a fault and faults are cleared as quickly as possible. It is the utility's perspective that we are focused on here. From the customer's perspective the only time that imbalance may be at issue is when, as in OP's case, the utility monitors and charges for imbalance. The other case might be in sizing backup generating equipment. In my house I have three panels and I have thought about installing a backup generator. It sort of seems to make sense that I hook up each panel to one of the phases of a 3ø generator. Clearly, here, the generator would not be presented a symmetrical load since two of the panels have air conditioners on them and one doesn't. Thus, in cooling season, that generator would have to deal with considerable negative sequence current, would experience additional temperature rise and would have to be de-rated.

The10mmKid

Well-Known Member

Hey Podz,

Could you please post some images of your completed panel guts?

I'm curious about how the branch circuits are jumpered back to the mains.

Thanks,

'da Kid

Could you please post some images of your completed panel guts?

I'm curious about how the branch circuits are jumpered back to the mains.

Thanks,

'da Kid

The10mmKid

Well-Known Member

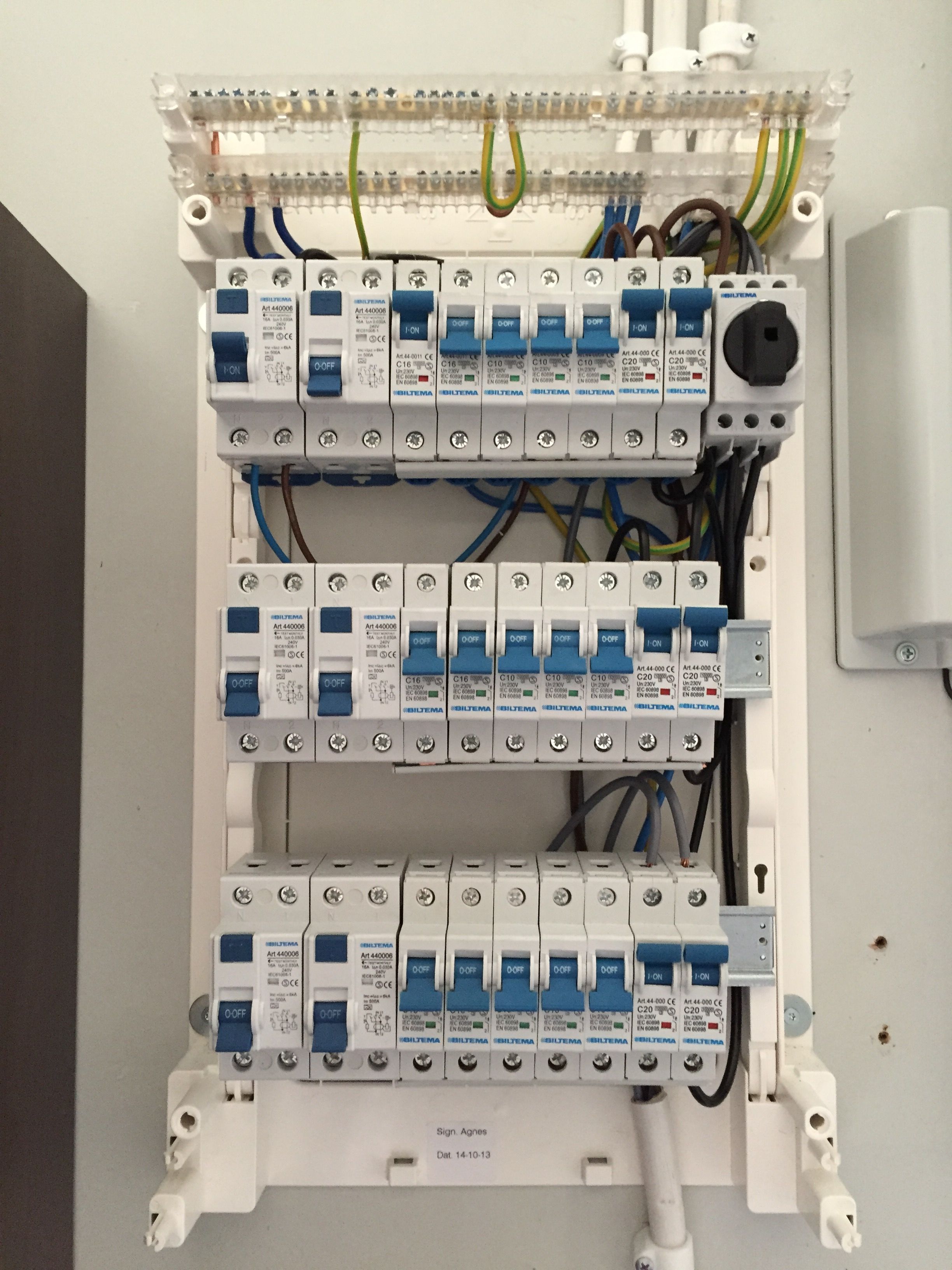

Excellent, just as I pictured in my head.

In my line of work, LINE almost without exception comes into the top of the breaker and LOAD exits the bottom.

Interesting that a ground fault will open the bad circuit and five of it's friends on that phase.

Podz, what condition exists when just one of the ground fault protectors trip on a 3-phase appliance? (I'm assuming the remaining two hold)

Thanks,

'da Kid

In my line of work, LINE almost without exception comes into the top of the breaker and LOAD exits the bottom.

Interesting that a ground fault will open the bad circuit and five of it's friends on that phase.

Podz, what condition exists when just one of the ground fault protectors trip on a 3-phase appliance? (I'm assuming the remaining two hold)

Thanks,

'da Kid

He hasn't shown you a picture of his box or even of the components in his box. For a magnetic/thermal breaker it doesn't matter which is input and which is output unless the panel in which the breaker is installed has wire lugs on one side and some sort of other terminals to mate with bus bars, for example, on the other.Excellent, just as I pictured in my head.

In my line of work, LINE almost without exception comes into the top of the breaker and LOAD exits the bottom.

I thought that was interesting too. Going to make for some interesting trouble shooting sessions.Interesting that a ground fault will open the bad circuit and five of it's friends on that phase.

He hasn't shown us connections for any three phase appliances. Just single phase branch circuits distributed across three phases. In all the stuff I've seen where a three phase load was protected by a GFCI/ELCB (or whatever you want to call it) the three phase conductors and the neutral all went through the doughnut in the breaker. Any current from any phase that did not return through one of the other phases or the neutral would trip the breaker disconnecting all three phases. Similarly, any magnetic or thermal overload on a single phase would trip the breaker and interrupt all 3.Podz, what condition exists when just one of the ground fault protectors trip on a 3-phase appliance? (I'm assuming the remaining two hold)

Does the main neutral bar get bonded to earth?

That diagram was just an example. I will try to get swmbo to help me take some photos today.

My design is different: I don't protect more than 1 circuit per residual current device, in order to avoid nuisance tripping. Also, I put the RCDs at the end of the row instead of the beginning so I can use bus bars to interconnect the breakers.

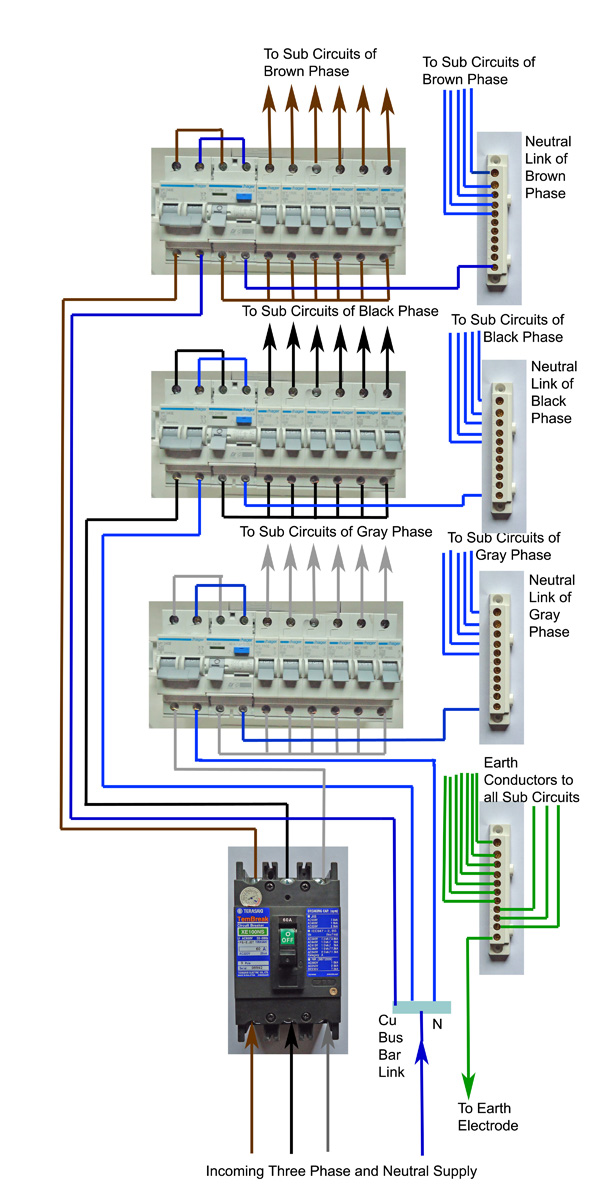

Similar to this:

I feed three-phase down to both of my sub panels with a single 20 amp breaker per phase in order to minimise outages, but my stove and brewing outlet are on 16 amp 3-pole simultaneous-trip breakers.

Stove doesn't require an RCD by code, but I do require one for my brewing outlet. I mounted it in a separate case since I didn't want to build a 3-row sub panel for the garage.

My design is different: I don't protect more than 1 circuit per residual current device, in order to avoid nuisance tripping. Also, I put the RCDs at the end of the row instead of the beginning so I can use bus bars to interconnect the breakers.

Similar to this:

I feed three-phase down to both of my sub panels with a single 20 amp breaker per phase in order to minimise outages, but my stove and brewing outlet are on 16 amp 3-pole simultaneous-trip breakers.

Stove doesn't require an RCD by code, but I do require one for my brewing outlet. I mounted it in a separate case since I didn't want to build a 3-row sub panel for the garage.

Does the main neutral bar get bonded to earth?

Yes, I have a TN-C system with PEN coming from the utility. And I'm only running one neutral bar anyway since I never protect more than a single circuit with a single RCD - just wire them straight together.

He hasn't shown you a picture of his box or even of the components in his box. For a magnetic/thermal breaker it doesn't matter which is input and which is output unless the panel in which the breaker is installed has wire lugs on one side and some sort of other terminals to mate with bus bars, for example, on the other.

DIN standard mini circuit breakers have places for wires as well as bus bars on both top and bottom so you have flexibility when wiring them up. Handy for the first circuit on a row, for example, where you can connect both a feed wire as well as a bus bar to feed the rest of the row faster.

We have three-phase bus bars as well. I use one in my kitchen sub panel because it's only a 1 row box. It looks like this:

Does the main neutral bar get bonded to earth?

As you are running separate neutral and protective conductors inside the building that would make it a TN-C-S. The grounding electrode puzzles me though. I'd be tempted to call that T(T/N)-C-S but there is, AFAIK, no such thing in IEC parlance. The NEC system is described as TN-C-S but also has the grounding electrode requirement at the service entrance.Yes, I have a TN-C system with PEN coming from the utility.

Anyway, it is most interesting to those of use completely parochialised by the NEC to get some exposure to how things are done in the rest of the world.

Yes, I have a TN-C system with PEN coming from the utility.

I see. Well, I was actually completely lost until I did a little reading.

As you are running separate neutral and protective conductors inside the building that would make it a TN-C-S. The grounding electrode puzzles me though. I'd be tempted to call that T(T/N)-C-S but there is, AFAIK, no such thing in IEC parlance. The NEC system is described as TN-C-S but also has the grounding electrode requirement at the service entrance.

Anyway, it is most interesting to those of use completely parochialised by the NEC to get some exposure to how things are done in the rest of the world.

I see your point. Although this terminoligy is new to me, I do not see a standard configuration that includes a grounding electrode. As an installer of many a ground rod, it seems ridiculous especially when much better grounding (earthing) options are available and actually requred to be used before driven rods.

I am enjoying the exposure to how things are done in the rest of the world. I have certainly learned a few things here and even if it is for curiosity's sake, it is valuable to me.

This old house doesn't have an equipotential bar, though I should install one and bury some copper in the yard. Connected to it should be the main breaker panel, rebar in the house, pipes, the metal roof, TV antenna, and ADSL connection.

Anyway, I've got neutral bonded to ground inside of the main panel and isolated inside the sub panels.

Still got four circuits waiting to migrate to the new panel. Those are a real pain because they trail through multiple rooms.

Anyway, I've got neutral bonded to ground inside of the main panel and isolated inside the sub panels.

Still got four circuits waiting to migrate to the new panel. Those are a real pain because they trail through multiple rooms.

This old house doesn't have an equipotential bar, though I should install one and bury some copper in the yard. Connected to it should be the main breaker panel, rebar in the house, pipes, the metal roof, TV antenna, and ADSL connection.

Anyway, I've got neutral bonded to ground inside of the main panel and isolated inside the sub panels.

Still got four circuits waiting to migrate to the new panel. Those are a real pain because they trail through multiple rooms.

So the way I understand, you will drive a rod (or use an existing electrode of some sort) and bond that to your supplied neutral in the main panel? Then the (equipment ground) is isolated in the subpanels...finally something that makes sense to me.

I would really like to see some pictures of your surface mount installation. That seems to be a last resort around these parts. Maybe you Europeans have a sexy way of doing it that we don't know about

There really is no need to do that unless you have special requirements of some sort (swimming pool, milking parlour...) and even in those cases the best approach is an equipotential surface around the pool etc. rather than lower impedance to earth. In the US the requirement is that the impedance be 25 Ω or less. A single rod is usually sufficient but if you have uncooperative soil a second one may be required.This old house doesn't have an equipotential bar, though I should install one and bury some copper in the yard.

If there is a problem with the PEN being above earth it is usually a problem with the utility and then often a poor connection in the neutral on the primary side. With the careful monitoring of phase imbalance you describe neutral current should be low. Does the utility run a Multiply Grounded Neutral? I would think they would given the northern latitude.

For example if my roof gets hit by lightning, it's currently ungrounded. It's a full metal roof.

Ground rods aren't allowed in the EU for new installations and I have never seen them here anyway. Minimum of 16mm2 cross section copper rope buried 80cm deep in a ring around the entire house, or 2x20m long sections if the ring is not physically possible. This is an EU-wide regulation.

Example:

Also look at pictures 3, 4, and 5 for allowed alternatives. Pictures 1 and 2 were the previous standard, so can be regularly encountered.

http://www.paneliankoskenvoima.fi/tuotteet-ja-palvelut-uusi-liittyma/maadoitus

Ground rods aren't allowed in the EU for new installations and I have never seen them here anyway. Minimum of 16mm2 cross section copper rope buried 80cm deep in a ring around the entire house, or 2x20m long sections if the ring is not physically possible. This is an EU-wide regulation.

Example:

Also look at pictures 3, 4, and 5 for allowed alternatives. Pictures 1 and 2 were the previous standard, so can be regularly encountered.

http://www.paneliankoskenvoima.fi/tuotteet-ja-palvelut-uusi-liittyma/maadoitus

Again, most interesting. In the US and Canada the realization that Fig. 2 is the safest is beginning to be accepted and is now required (in the US) around swimming pools. I have several times mentioned here that it would be the best for the electric, or any, for that matter, brewery and were I to redo my home setup would probably put a grid in the floor. A ground rod or rod or anything with < 25 Ω impedance is still required. That may seem high but I just checked my rod and it is 20 Ω but only injecting 13 mA into mother earth at the moment implying that the protective conductors in my house are 260 mV above ground. Clearly the system works.

Now if my earthing systems impedance were lower the voltage rise would be less. A loop buried 0.8 m deep would doubtless give a lower impedance here in VA but would it in Canada or Finland where I expect, at this time of year, that it would be imbedded in ice? Ground rods must be 2.5 m long in order to be sure that they reach below the frost line.

In the US and Canada most grounding problems, as I noted in an earlier post, seem to arise from problems with the primary neutral (corroded wire connectors) but that's because the utilities in those countries distribute the primary in a Y connection. This allows them to use lower voltage, single bushing transformers. It would be possible to protect consumers from neutral problems by installing devices which monitor the difference between earth and neutral voltage and isolate the PEN line to the consumer from the primary neutral if that rises. These cost money and the utilities generally dig in their heels when problems arise and blame inadequate grounding on users premises for the problem rather than install the devices. Given that 3ø is being distributed in Finland the utility has to be buying 3 bushing transformers anyway and so may be using a ∆ primary connection thus eliminating problems with primary neutrals by eliminating the neutral. The down side there is that more reliance must be placed on the customer's earthing. His only connections to Mother are at his premises and at the transformer. In the Y-connected MGN system he is connected to the neutrals at his premises, at his transformer, at every other transformer connected to the substation and every quarter mile in runs where there are no transformers.

Now if my earthing systems impedance were lower the voltage rise would be less. A loop buried 0.8 m deep would doubtless give a lower impedance here in VA but would it in Canada or Finland where I expect, at this time of year, that it would be imbedded in ice? Ground rods must be 2.5 m long in order to be sure that they reach below the frost line.

In the US and Canada most grounding problems, as I noted in an earlier post, seem to arise from problems with the primary neutral (corroded wire connectors) but that's because the utilities in those countries distribute the primary in a Y connection. This allows them to use lower voltage, single bushing transformers. It would be possible to protect consumers from neutral problems by installing devices which monitor the difference between earth and neutral voltage and isolate the PEN line to the consumer from the primary neutral if that rises. These cost money and the utilities generally dig in their heels when problems arise and blame inadequate grounding on users premises for the problem rather than install the devices. Given that 3ø is being distributed in Finland the utility has to be buying 3 bushing transformers anyway and so may be using a ∆ primary connection thus eliminating problems with primary neutrals by eliminating the neutral. The down side there is that more reliance must be placed on the customer's earthing. His only connections to Mother are at his premises and at the transformer. In the Y-connected MGN system he is connected to the neutrals at his premises, at his transformer, at every other transformer connected to the substation and every quarter mile in runs where there are no transformers.

80cm is the min depth, but of course impedance testing is required before taking into use. the primary intention of the circular loop is remote lightning strike protection, i.e current traveling across the ground, which happens during the time when the ground isn't frozen.

We also have a very shallow bedrock across most of the nordic regions... rock is exposed in many places, even in my yard. Driving a ground rod would require some heavy drilling and probably be pointless in the end.

finally got some photos inside my panel, will upload them later.

We also have a very shallow bedrock across most of the nordic regions... rock is exposed in many places, even in my yard. Driving a ground rod would require some heavy drilling and probably be pointless in the end.

finally got some photos inside my panel, will upload them later.

The problem you get into there is that a strike at one 'end' of the distributed ground injects HUGE current into the ground in its vicinity resulting in very large, very steep gradients. These induce very large currents in the grounding system some of which, on their way to the true earth potential at the transformer, may magnetically couple to the phases and damage electronic equipment. So that relates back to the question as to whether your utility uses a multiply grounded neutral (or a neutral at all). These are important in Canada (though they are used in the US as well) because of the large potential gradients induced by solar events. Even with MGN a CME in March 1989 wiped out Quebec's power grid. Shallow bedrock was cited as contributing to the problem. I'd guess it would be the same there.80cm is the min depth, but of course impedance testing is required before taking into use. the primary intention of the circular loop is remote lightning strike protection, i.e current traveling across the ground, which happens during the time when the ground isn't frozen.

What is the grounding system impedance requirement there?

We also have a very shallow bedrock across most of the nordic regions... rock is exposed in many places, even in my yard.

Same for my house in Quebec. I'm guessing that they built it onto the side of the hill rather than into the side of the hill but nevertheless it is earthed with a rod and the generator has another rod. Modern thinking is that that second rod shouldn't be there (because of the lightning strike problem mentioned above) and I've seen that one of the largest generator manufacturers in North America has removed installation of a rod from its installation instructions. I used to think the more wire you had in the dirt the better i.e. lower earth impedance had to be better than higher earth impedance but I am beginning to be swayed by the lightning argument.

Driving a ground rod would require some heavy drilling and probably be pointless in the end.

The obvious question then is that if you can't dig a hole below frost line for a rod how do you dig a trench below frost line for a cable?

Obviously, no one has yet come up with a completely foolproof method of grounding. Solve one problem and another pops up, it seems. This is why I tend to favor the grid under the floor approach. It doesn't matter if your grounding system goes to 10 kV above earth. You won't be standing on earth, you will be standing on the grid and all your equipment/wiring is at its potential. But I'm sure that system has some pitfalls too.

What is the grounding system impedance requirement there?

Sorry for being short, but the hand...

http://fi.wikipedia.org/wiki/Sähköa...otentiaalintasausjohtimen_jatkuvuuden_testaus

Mittauksen suojajohtimen hyväksyttävä mittausarvo on 0,13 ohmia.

So, between 0.1 and 3 ohms.

No problem. Just curious. Please don't worry about it any further.Sorry for being short, but the hand...

So, between 0.1 and 3 ohms.Mittauksen suojajohtimen hyväksyttävä mittausarvo on 0,13 ohmia.

That actually refers to the protective conductor (no, I don't know any Finnish - the only word I know in the whole Finno-Ugric system is 'Sor', the Hungarian word for beer). I meant the requirement for the impedance between the grounding rod terminal and the earth. I (probably obviously) got the translation for the quote above from Google Translate and looked over the rest of the page. The translation isn't great but I did see reference to testing with inductive type meters but no acceptable value.

ajdelange said:That actually refers to the protective conductor (no, I don't know any Finnish - the only word I know in the whole Finno-Ugric system is 'Sor', the Hungarian word for beer). I meant the requirement for the impedance between the grounding rod terminal and the earth. I (probably obviously) got the translation for the quote above from Google Translate and looked over the rest of the page. The translation isn't great but I did see reference to testing with inductive type meters but no acceptable value.

I don't know what the impedance should be, need to ask my electrician who does the testing.

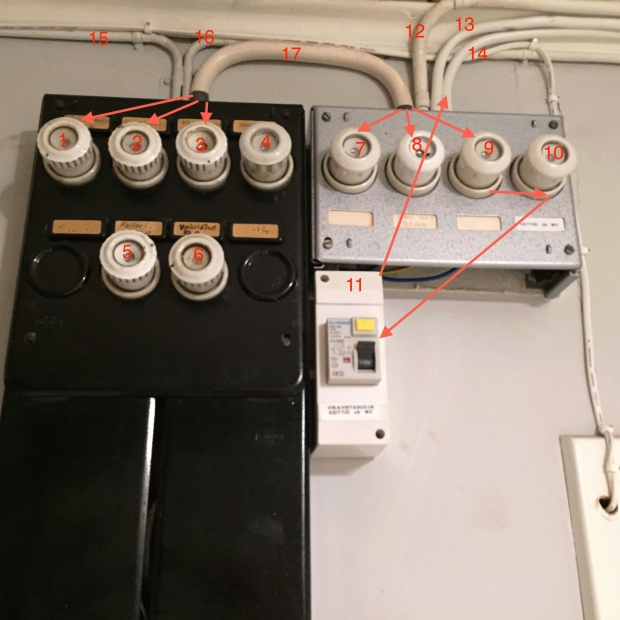

This was the beginning - prior to doing any work. Very old and dangerous setup.

1. 16 amp fuse feeding garage sub-panel (L1), also hotwired to 7 via cable 17

2. 16 amp fuse feeding garage sub-panel (L2), also hotwired to 8 via cable 17

3. 16 amp fuse feeding garage sub-panel (L3), also hotwired to 9 via cable 17

4. 10 amp fuse feeding entire ground floor (kitchen, living room and bedroom) via cable 16

5. 16 amp fuse feeding most of the basement

6. 10 amp fuse feeding two outside lights via cable 15

7. 16 amp fuse feeding stove L1 via cable 12

8. 16 amp fuse feeding stove L2 via cable 12

9. 16 amp fuse feeding stove L3 via cable 12, also wired to 10 to feed 11

10. 16 amp fuse feeding RCD 11

11. 40 amp RCD feeding a wall socket-lamp combo in the kitchen via cable 13 and the bathroom via cable 14

Similar threads

- Replies

- 5

- Views

- 2K

- Replies

- 15

- Views

- 1K

- Replies

- 0

- Views

- 839

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)