You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3-phase split load design

- Thread starter podz

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

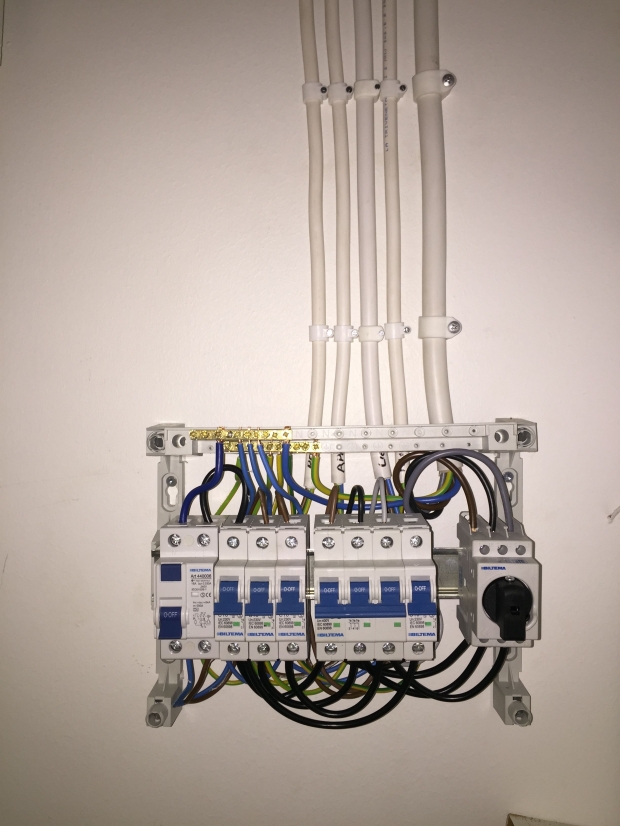

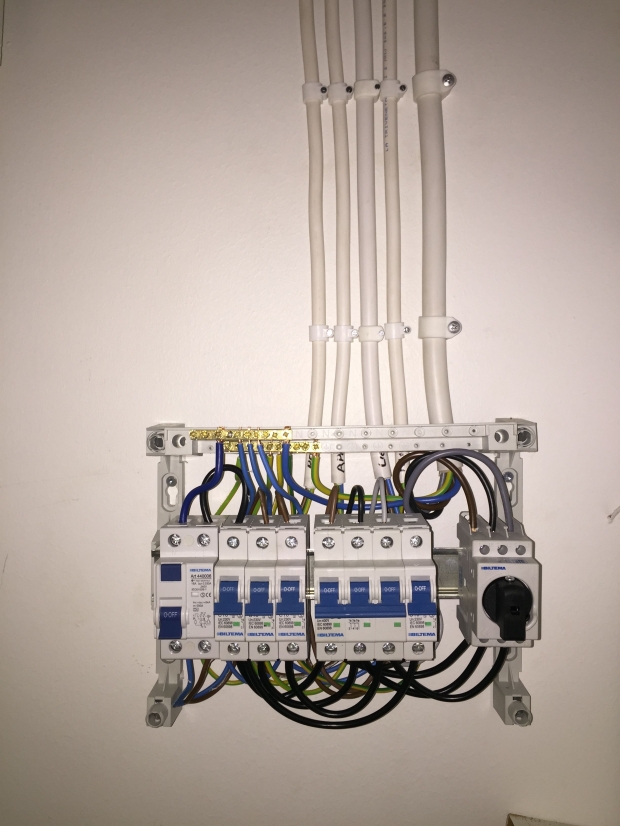

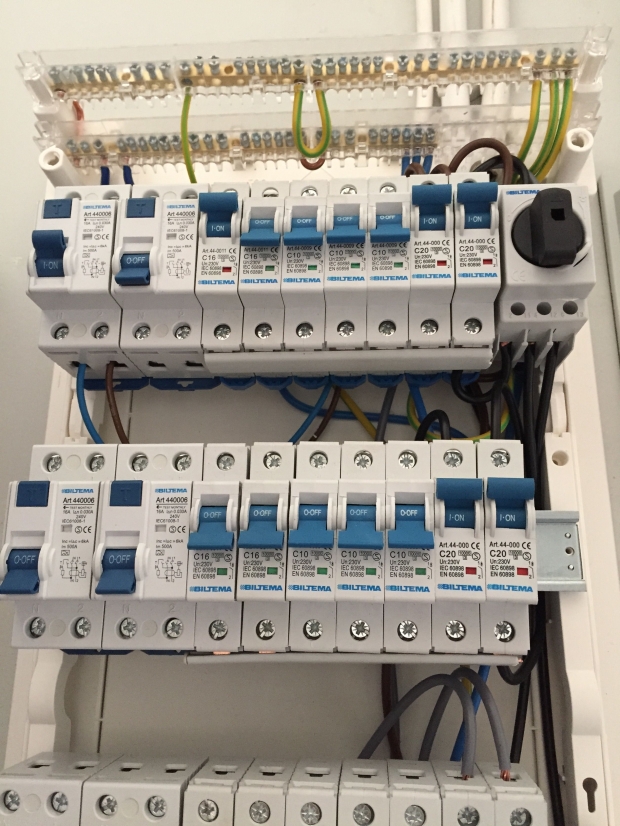

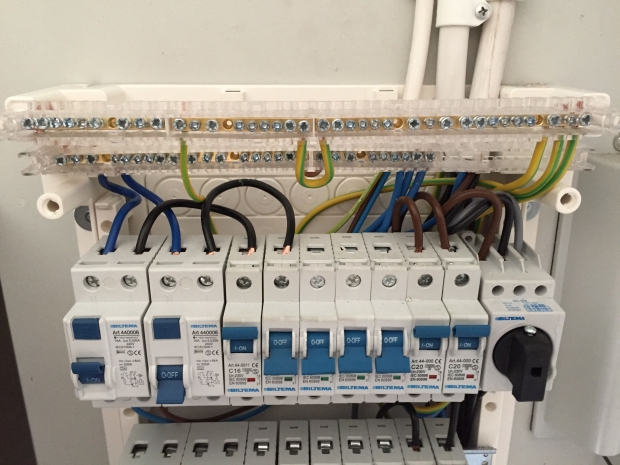

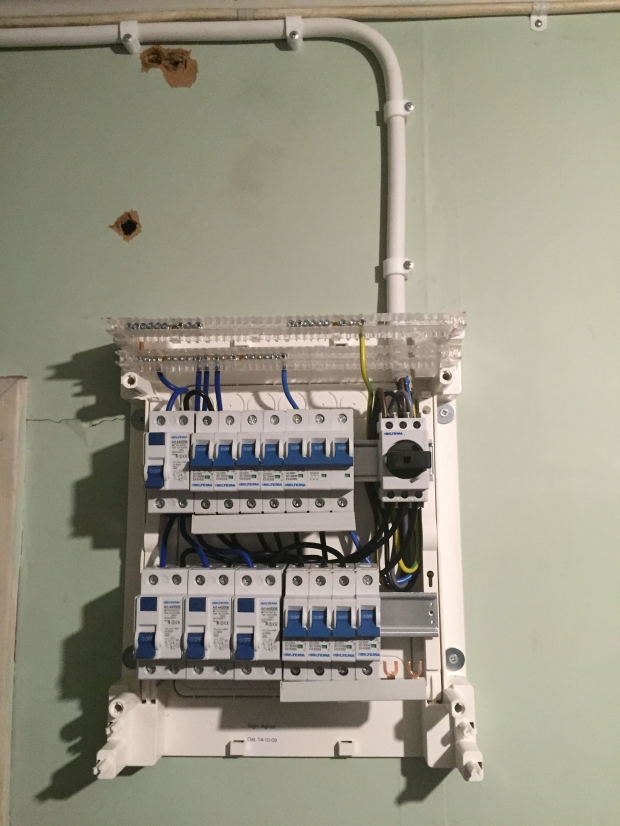

New sub panel in the kitchen. Lamp breaker on the far right isn't wired up in that photo. Three phases without bus bar, just wired the breakers together on the bottom side by hopping over. The second breaker on the right is a three-phase simultaneous trip breaker, feeds the stove. There is only one RCD here, for the general-purpose sockets.

Yes, now I finally have a dedicated 16 amp 3-phase circuit and outlet in my garage with it's very own RCD (GFCI).

Now to start shopping for a 3-phase stainless steel water heating element. I'm guessing 8000 watts max for this circuit (line to line voltage of 400, power factor .8). How does that sound?

Now to start shopping for a 3-phase stainless steel water heating element. I'm guessing 8000 watts max for this circuit (line to line voltage of 400, power factor .8). How does that sound?

BazzookaBuddy

Member

- Joined

- Mar 15, 2014

- Messages

- 13

- Reaction score

- 1

Nice thread post. Quite interesting to read since I'm from Sweden and most of the threads here are related to American standards.

Let me know what element you purchase and your experience with it. I'm on the same route as you are.

Let me know what element you purchase and your experience with it. I'm on the same route as you are.

Nice thread post. Quite interesting to read since I'm from Sweden and most of the threads here are related to American standards.

Let me know what element you purchase and your experience with it. I'm on the same route as you are.

Here is an 8.5 kW 3-phase stainless steel element for 342 EUR including tax (damned expensive). I'd like to find something about half that price! But anyway, that should still run without tripping a 16 amp circuit.

http://www.esska-fi.com/esska_fi_s/...erre-2-messinki-korkki-505340200000-6540.html

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

The10mmKid

Well-Known Member

Might be worth checking one of our American suppliers:

https://www.watlow.com/downloads/en/catalogs/immersion.pdf

You'll have to 'up' your wattage since we're at 480V.

'da Kid

https://www.watlow.com/downloads/en/catalogs/immersion.pdf

You'll have to 'up' your wattage since we're at 480V.

'da Kid

Might be worth checking one of our American suppliers:

https://www.watlow.com/downloads/en/catalogs/immersion.pdf

You'll have to 'up' your wattage since we're at 480V.

'da Kid

You can not import electrical devices into the European Union unless they are CE marked. That is roughly the US equivalent of UL marking. They simply won't make it through customs.

http://ec.europa.eu/enterprise/policies/single-market-goods/cemarking/

In addition, every country has it's own organisation that needs to approve all electrical devices being imported or sold in that country. For example, in Germany it's called "TÜV" and in Finland it's called TUKES.

Now that I have a 3-phase outlet in the garage, I am able to connect one of these (a circuit box meant originally for construction sites):

It's got a 16 amp 3-phase input, then 2 x 16 amp 3-phase outputs and 4 x 16 amp 1-phase outputs (2 per circuit). 2 x 16 amp circuit breakers for the 1-phase sockets and a 40 amp RCD (GFCI) for the entire thing.

I can connect a 10 meter 3-phase extension cord to the outlet in the garage and then mount this thing to my brew rig and take it out in the yard! Or use a 3-phase welder, etc.

Do you have such devices in the US? This one only costs 67 EUR.

It's got a 16 amp 3-phase input, then 2 x 16 amp 3-phase outputs and 4 x 16 amp 1-phase outputs (2 per circuit). 2 x 16 amp circuit breakers for the 1-phase sockets and a 40 amp RCD (GFCI) for the entire thing.

I can connect a 10 meter 3-phase extension cord to the outlet in the garage and then mount this thing to my brew rig and take it out in the yard! Or use a 3-phase welder, etc.

Do you have such devices in the US? This one only costs 67 EUR.

The10mmKid

Well-Known Member

Now that I have a 3-phase outlet in the garage, I am able to connect one of these (a circuit box meant originally for construction sites):

It's got a 16 amp 3-phase input, then 2 x 16 amp 3-phase outputs and 4 x 16 amp 1-phase outputs (2 per circuit). 2 x 16 amp circuit breakers for the 1-phase sockets and a 40 amp RCD (GFCI) for the entire thing.

I can connect a 10 meter 3-phase extension cord to the outlet in the garage and then mount this thing to my brew rig and take it out in the yard! Or use a 3-phase welder, etc.

Do you have such devices in the US? This one only costs 67 EUR.

OMG, heck no we don't have anything as gorgeous as that. Here is our closest sad equivalent.

The10mmKid

Well-Known Member

Still might be worth looking in to:

http://www.watlow.com/common/downloads_bak/en/agency/9999-0241-0000-L-Public.pdf

http://www.watlow.com/common/downloads_bak/en/agency/9999-0241-0000-L-Public.pdf

You can not import electrical devices into the European Union unless they are CE marked. That is roughly the US equivalent of UL marking. They simply won't make it through customs.

http://ec.europa.eu/enterprise/policies/single-market-goods/cemarking/

In addition, every country has it's own organisation that needs to approve all electrical devices being imported or sold in that country. For example, in Germany it's called "TÜV" and in Finland it's called TUKES.

OMG, heck no we don't have anything as gorgeous as that. Here is our closest sad equivalent.

That is really sad, indeed.

I don't think so, because homes are not wired 3ø in the US (people that want 3ø here have to make it from single phase). Nor do I remember seeing anything like that around shop floors or in labs or office buildings but that prove that they don't exist here.Do you have such devices in the US?

Curious as to why only two of the phases are supplied to single phase outlets. Are you fed corner delta?

Actually, I guess that's a pretty dumb question as previous posts make it pretty clear you are not.

I don't thing so, because homes are not wired 3ø in the US (people that want 3ø here have to make it from single phase). Nor do I remember seeing anything like that around shop floors or in labs or office buildings but that prove that they don't exist here.

Curious as to why only two of the phases are supplied to single phase outlets. Are you fed corner delta?

I think it just comes down to less of a risk of overloading the feeding 3-phase breakers. That, and symmetry. There are all sorts of different designs of these devices, this is a cheap one but it's IP44 and not supplied with it's own (restricted length) feeder cable, which I like.

- Joined

- Apr 11, 2013

- Messages

- 376

- Reaction score

- 61

What I am a bit jealous of is your 3ø power. I could do so much more at home if i had that.

A quick note. This is what I'm used to for quick power distribution on job sites in the US.

A quick note. This is what I'm used to for quick power distribution on job sites in the US.

What I am a bit jealous of is your 3ø power. I could do so much more at home if i had that.

A quick note. This is what I'm used to for quick power distribution on job sites in the US.

All houses here have it but most people don't use it for other than fixed-wire appliances like the stove, hot water heater, sauna heater, or underfloor heating.

Usually the only people who install a general purpose 3-phase socket are those who are welding or running some sort of workshop at home, which is like less than 1% of the population here.

What exactly would you do with 3-phase power if you had it at home?

The big advantages of 3ø are in motors and rectifiers. The former don't need starting/running capacitors and the latter have much lower inherent ripple. Most homeowners in the US who have 3ø equipment seem to be enthusiastic wood or metal workers who have obtained used factory planers, saws, lathes, milling machines... that have 3ø motors in them. Most of these guys make 3ø from the single phase coming into their houses by using a single-phased 3ø induction motor or simple capacitor based phase shifting circuits. There are lots of videos, etc., on the web that show how this is done.

Given the above I find it surprising that most of the 3ø loads in homes in Finland seem to be resistive. Are you saying that compressor motors in home heat pumps, for example, would be single phase?

Given the above I find it surprising that most of the 3ø loads in homes in Finland seem to be resistive. Are you saying that compressor motors in home heat pumps, for example, would be single phase?

- Joined

- Apr 11, 2013

- Messages

- 376

- Reaction score

- 61

Thanks for asking, as you seem pretty well versed in the world of electricity. Even from simple everyday things like a washing machine. Three phase power can increase your own electrical efficiency pretty tremendously.

From a common point between the two of us. Brewing. Meeting the power demands of a electric brewing rig can be quite daunting for brewers in the US. Many of the designs I see on HBT take into account the limitations of a bi-phase service and thus we are stuck with limited wattage.

Not to say that you don't have your own limitations with what you have.

I would certainly be interested in having the ability to use 3 phase motors, welders, and such things for a shop setup though.

I pulled this little blerb from another site which supports my jealousy. Mainly from an efficiency point of view.

From a common point between the two of us. Brewing. Meeting the power demands of a electric brewing rig can be quite daunting for brewers in the US. Many of the designs I see on HBT take into account the limitations of a bi-phase service and thus we are stuck with limited wattage.

Not to say that you don't have your own limitations with what you have.

I would certainly be interested in having the ability to use 3 phase motors, welders, and such things for a shop setup though.

I pulled this little blerb from another site which supports my jealousy. Mainly from an efficiency point of view.

I remember asking an engineering professor that same question. I.E. If a three phase motor is more efficient than single phase, how huch more efficient is it? He said without hesitation, "20 percent". I don't know if that is true, and that was in 1980, so things may have changed somewhat since then. However, you still can't get something for nothing. Compare full load amps on each machine. That's where the HP calculation comes from, so they can't be too far away from each other. One way of looking at the whole question would be to approach it form the "green" point of view and consider how much copper and iron are going to produce the same effect. As Tony says, "Looks can be deceiving". Generally, the 1 ph motor will have twice as much copper and iron as the 3 ph motor. That extra stuff is devoted exclusively to starting the 1 ph motor. When it gets up to normal operating speed, the centrifugal switch takes it out of the circuit. And as said earlier, the 3 ph motor runs cooler. I would attribute some of that to the start function in the 1 ph motor. WWQ

Are you saying that compressor motors in home heat pumps, for example, would be single phase?

For geothermal heat pumps, the motor is either to be wired as 3-phase or 1-phase connected via a safety switch. A safety switch is a switch that shuts off power if it notices the wire heating up i.e. the motor is not spinning for some reason.

The motor that circulates hot water in my house for heating and showers is wired with a safety switch. And it's a real bitch because every time I shut off power to the house, that motor refuses to restart on it's own. I need to unmount it, stand it on a shelf and hit the fins with my finger to kick start them. Then I need to let it run like that for about 15 minutes before it will restart on it's own with the safety switch before I can remount it.

Not to say that you don't have your own limitations with what you have.

Yes, well for example in Finland you can't get more than 3 x 63 amp service to a residence. That flatly eliminates any possibility of a 64 amp 3-phase residential power outlet. So, in practice, residential 3-phase is limited to a 32 amp outlet. Mine is limited to 16 amp because my service is 3 x 25 amp (3-phase outlets that you can buy for home use are either 16 or 32 amps).

Of course I have 6 x 20 amp breakers in my main panel that I feed down to 3-pole 16 amp breakers in my sub panels.

Not sure if the calculation is correct, but with 400v, 3-phase, power factor 0.8, an 8500 watt element should pull about 15.5 amps. So, that will clearly fit within my 16 amp circuit. I don't know if that power factor is correct or not, I just guessed it.

Assuming I heat 25 litres of water from 20c to 100c with an 8500 watt element, it should take 16.5 minutes. Not bad.

http://processheatingservices.com/water-heating-time-calculator/

I assume that you mean it can be either a 3ø motor or a single phase motor but not a 3ø motor wired single phase. This does work if you can get it started but is certainly hard on the motor and clearly presents an asymmetric load to the system.For geothermal heat pumps, the motor is either to be wired as 3-phase or 1-phase connected via a safety switch. A safety switch is a switch that shuts off power if it notices the wire heating up i.e. the motor is not spinning for some reason.

Both single phase and 3ø motors will be equipped with some sort of protection against the locked rotor condition. This can be an overcurrent sensor (fuse, magnetic or thermal or combination circuit breaker) or sometimes just a thermally operated switch on the motor which opens if the motor gets too hot and can be reset manually ((typical for garbage disposal units) or automatically when it cools. 3ø motors are often equipped with single phasing detectors (one phase fails) as well.

Of course I have no idea what you actually have there but if it is a single phase motor with a starting or starting/running capacitor I'd check that. Also see if you can clean/lubricate the bearings. Circulating pumps in heating systems are usually pretty puny and often don't have the starting circuitry (they are shaded pole construction) in which case it may just be the bearings are binding.The motor that circulates hot water in my house for heating and showers is wired with a safety switch. And it's a real bitch because every time I shut off power to the house, that motor refuses to restart on it's own. I need to unmount it, stand it on a shelf and hit the fins with my finger to kick start them. Then I need to let it run like that for about 15 minutes before it will restart on it's own with the safety switch before I can remount it.

Unbelievable. That's less than 50 KVA. I guess pottery isn't a common hobby over there. In the US they'll install as much as you are willing to pay for - even three phase if you want it (you don't when you see the price tag). I have, for example, three 200 Amp bi-phase panels for a total of 144 KVA installed. No, I'm not Al Gore. My average load over the last year has been 3.75 KW. The house is relatively small but it has been added on to twice and each time they installed another 200 amp panel (total of 3). When the utility saw that they just put a bigger transformer on the pole (and sent me a bill).Yes, well for example in Finland you can't get more than 3 x 63 amp service to a residence.

The10mmKid

Well-Known Member

Podz,

I've noticed your pics show 'surface mounted' cabling. Are any wires concealed in the walls, attics, sub flooring?

'da Kid

I've noticed your pics show 'surface mounted' cabling. Are any wires concealed in the walls, attics, sub flooring?

'da Kid

Unbelievable. That's less than 50 KVA. I guess pottery isn't a common hobby over there.

Not many home potters, no.

Additionally, the maximum allowable size for a single phase circuit is 16 amps and that has to run on 2,5mm2 wire, which would be the equivalent of 13 AWG if such a size existed. In other words, no 240v sockets are sold here with a rating of greater than 16 amps and bypassing this will void your home insurance.

You have to remember, though, that we are running 240v single phase and 400v 3-phase, so the amperage requirements are much lower. I haven't yet seen a 3-phase MIG welder that won't run on a 16 amp circuit at 400v.

I believe, but have no proof, that the 63 amp restriction is political. 3-phase power comes in 16, 32, 64 amp and so on. Businesses that pay business-rate electricity prices don't want people to get away with running 64 amp 3-phase on residential rates (creates competition, and the european way is all about locking new competition out).

QUOTE=podz;6813858]

You have to remember, though, that we are running 240v single phase and 400v 3-phase, so the amperage requirements are much lower. I haven't yet seen a 3-phase MIG welder that won't run on a 16 amp circuit at 400v.[/QUOTE] If you delta connect you can get 3*63*240*sqrt(3) = 78.6 kVA which is certainly better but still not a lot by comparison to what one finds in the American McMansion. Again, though, we note that the average load drawn is usually only a few percent of the installed capacity.

You have to remember, though, that we are running 240v single phase and 400v 3-phase, so the amperage requirements are much lower. I haven't yet seen a 3-phase MIG welder that won't run on a 16 amp circuit at 400v.[/QUOTE] If you delta connect you can get 3*63*240*sqrt(3) = 78.6 kVA which is certainly better but still not a lot by comparison to what one finds in the American McMansion. Again, though, we note that the average load drawn is usually only a few percent of the installed capacity.

I figured as much but wanted to step delicately around that and though I am tempted to add some further comments will refrain from doing so.I believe, but have no proof, that the 63 amp restriction is political.

Podz,

I've noticed your pics show 'surface mounted' cabling. Are any wires concealed in the walls, attics, sub flooring?

'da Kid

Not in this house, except for the cable that runs between the feed fuses and the main circuit panel. And that will be replaced with surface mount soon. My walls are full of sawdust as insulation and soundproofing and I don't really want cables in there. The new way is to pull flexible plastic pipes and then pull individual cables inside of those, not the PVC coated cables like I have.

This is an old house built after the war when the government had to build 300 thousand new houses FAST for displaced citizens and returning war heroes. You can imagine the quality with which they built them at that speed. The oldest wires in my house are wrapped with woven cloth and coated with tar. Thank god they aren't feeding more than LED lamps at this time and will be replaced ASAP. I took apart one of the old light switches the other day and the coating on the wires had melted together.

I figured as much but wanted to step delicately around that and though I am tempted to add some further comments will refrain from doing so.

Be as it may, I am still able to run an 8.5kW heating element on my puny service whereas most of you are not able to do it even on your huge ass services. ;-)

Be as it may, I am still able to run an 8.5kW heating element on my puny service whereas most of you are not able to do it even on your huge ass services.

I have a 14 KW auxiliary heater in one of my air handlers. It's on a 60 amp breaker in a 200 amp panel. Thank heaven it rarely runs. Even this last winter which was unusually cold.

- Joined

- Apr 11, 2013

- Messages

- 376

- Reaction score

- 61

Please educate me. Why are you calculating your current with a power factor of .8? Your element should be pretty much purely resistive, no inductance or very very little.

Am I wrong in thinking this way. You should he able to calculate ampacity at 100% power factor. Either way that would correct your ampacity to a lower value .

[edit]

I was at work when I first posted this so I only gave it a little attention. Here is a touch more.

So I went ahead and did a little math for you. This is my math from using Python on my computer.

Here in the states it would be (8500/2)/120 = 35.5 amps. Which would require 2 X 8awg or (I think for metric) 3.5mm wire. Thats a pretty big difference between that and 3 X 14awg or 1.5mm wire if I had your electric system.

Am I wrong in thinking this way. You should he able to calculate ampacity at 100% power factor. Either way that would correct your ampacity to a lower value .

[edit]

I was at work when I first posted this so I only gave it a little attention. Here is a touch more.

So I went ahead and did a little math for you. This is my math from using Python on my computer.

Python 3.4.2 (v3.4.2:ab2c023a9432, Oct 6 2014, 22:15:05) [MSC v.1600 32 bit (In

tel)] on win32

Type "help", "copyright", "credits" or "license" for more information.

>>> import math

>>> rt3 = math.sqrt (3)

>>> lineVoltage = 400/rt3

>>> lineVoltage

230.94010767585033

>>> lineAmps = (8500/3.0)/lineVoltage

>>> lineAmps

12.268693220279546

>>>

Here in the states it would be (8500/2)/120 = 35.5 amps. Which would require 2 X 8awg or (I think for metric) 3.5mm wire. Thats a pretty big difference between that and 3 X 14awg or 1.5mm wire if I had your electric system.

Similar threads

- Replies

- 5

- Views

- 2K

- Replies

- 15

- Views

- 1K

- Replies

- 0

- Views

- 839

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)