You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3-in-1 "Boil Kettle, Jacketed Chiller, Conical Fermenter" by Brewha

- Thread starter MeetsCriteria

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

MeetsCriteria

Well-Known Member

Congratulations!

I did get the water chiller controller. I already have temp controllers so didn't need more in that regard.

Just saw this:

http://brewha.co/products/mash-colander

Did you get the BIAC? Since already have a HERMS set up so hard to justify at this point, but it is very intriguing...

I also got one of these from brewhemoth:

https://brewhemoth.com/pressurizer

It makes transfer via CO2 a breeze.

A word of caution. I almost exploded my 3-in-1 after my second brew session!

I had left the valve CLOSED on the blow off assembly after brewing. When I got up at 5 am the morning after brewing (having gone to bed at 0100) I saw no bubble activity but wasn't too surprised. I checked again at round 1400 and surprised that there was STILL no bubble activity. I had the gas in fitting from brewhemoth on the 3-in-1 with a pressure relief valve on it and for whatever reason pulled on the relieve valve. Gas shot out of there, like a keg pressurized to 20+ PSI. I looked at the valve on the blow-off assembly and couldn't believe it was closed.

I had the sudden feeling one standing next to a bomb must feel when they realize it's about to go off. The lid was noticeably convex up and I let off the pressure from the pressure relief valve, then opened the blow off valve. There was no apparent damage to the 3-in-1, but then it was blowing off co2 like crazy and it must have been moments away from blowing up.

So, be advised it's easy to leave that valve closed. Be careful! It's one thing to blow up a bucket...it's another to blow this thing up! The purpose of that valve of course is have a way to shut off the blow off assembly in order to push out the beer with CO2 if that's how you want to do it.

Good luck!

I did get the water chiller controller. I already have temp controllers so didn't need more in that regard.

Just saw this:

http://brewha.co/products/mash-colander

Did you get the BIAC? Since already have a HERMS set up so hard to justify at this point, but it is very intriguing...

I also got one of these from brewhemoth:

https://brewhemoth.com/pressurizer

It makes transfer via CO2 a breeze.

A word of caution. I almost exploded my 3-in-1 after my second brew session!

I had left the valve CLOSED on the blow off assembly after brewing. When I got up at 5 am the morning after brewing (having gone to bed at 0100) I saw no bubble activity but wasn't too surprised. I checked again at round 1400 and surprised that there was STILL no bubble activity. I had the gas in fitting from brewhemoth on the 3-in-1 with a pressure relief valve on it and for whatever reason pulled on the relieve valve. Gas shot out of there, like a keg pressurized to 20+ PSI. I looked at the valve on the blow-off assembly and couldn't believe it was closed.

I had the sudden feeling one standing next to a bomb must feel when they realize it's about to go off. The lid was noticeably convex up and I let off the pressure from the pressure relief valve, then opened the blow off valve. There was no apparent damage to the 3-in-1, but then it was blowing off co2 like crazy and it must have been moments away from blowing up.

So, be advised it's easy to leave that valve closed. Be careful! It's one thing to blow up a bucket...it's another to blow this thing up! The purpose of that valve of course is have a way to shut off the blow off assembly in order to push out the beer with CO2 if that's how you want to do it.

Good luck!

I didn't go with the BIAC - I plan on brewing 10g batches and would prefer to use a separate mash tun.

Is there any reason you added the brewhemoth pressurizer? I was under the impression you just add a ball lock (or pin lock) post to the included triclover fitting on the top of the lid?

Is there any reason you added the brewhemoth pressurizer? I was under the impression you just add a ball lock (or pin lock) post to the included triclover fitting on the top of the lid?

MeetsCriteria

Well-Known Member

I think the issue becomes HOW exactly does one "add" a ball lock to the tri-clover fitting.

The pressurizer is one such solution, which involves welding the fittings together. I am not aware of a direct off-the shelf compatible connection between a ball-lock fitting and a tri-clover fitting. But if you find a different solution, I am sure there will be many who are interested!

The pressurizer is one such solution, which involves welding the fittings together. I am not aware of a direct off-the shelf compatible connection between a ball-lock fitting and a tri-clover fitting. But if you find a different solution, I am sure there will be many who are interested!

I think the issue becomes HOW exactly does one "add" a ball lock to the tri-clover fitting.

The pressurizer is one such solution, which involves welding the fittings together. I am not aware of a direct off-the shelf compatible connection between a ball-lock fitting and a tri-clover fitting. But if you find a different solution, I am sure there will be many who are interested!

Am I wrong in thinking that I could just screw one of these into the included 1/4" threaded female triclover, then attach a ball lock post to this?

http://www.midwestsupplies.com/kegg...-fittings/cornelius-plug-adapter-1-4-mpt.html

MeetsCriteria

Well-Known Member

No, I think that would work nicely! Nice find!

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

abarnett

Well-Known Member

Despite the scientific explanation and seemingly sound line of reasoning, I subsequently elected to get an element with a stainless base, which is what I am using in the current batch. In the end, I asked myself if there was a stainless steel option, why would I NOT want it. There wasn't a clear answer to this question...

I'm sure I would have been fine had there not been a stainless steel option...I haven't seen the results of fermenting with the new element yet. My plan was to take a picture of it after fermentation is done and compare to the prior element. I'll post those results here.

I wasn't aware they made elements with stainless bases. Do you have a link for what you used?

Sent from my iPhone using Home Brew

MeetsCriteria

Well-Known Member

http://brewmation.com/Heating_Elements.html

Quick service from these guys. I got the 5500W 14" element. Once I get the batch out of the 3-in-1 (this weekend maybe?) I'll take pics of it's condition post fermentation.

Quick service from these guys. I got the 5500W 14" element. Once I get the batch out of the 3-in-1 (this weekend maybe?) I'll take pics of it's condition post fermentation.

KIAKillerXJ

Well-Known Member

Congratulations!

I did get the water chiller controller. I already have temp controllers so didn't need more in that regard.

Just saw this:

http://brewha.co/products/mash-colander

Did you get the BIAC? Since already have a HERMS set up so hard to justify at this point, but it is very intriguing...

I normally don't get all distracted my fancy brew objects, but I do love BIAB, and have been wanting to go electric, and have a nice conical. This setup looks PIMP, and the cost is totally justifiable! WANT!!

ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

Interesting concept....seems like the system is totally useable for someone who brews every other week. Primary fermentation actually doesn't take too long if you pitch properly....transferring to kegs could be done at the beginning of the brew day or the night before. Actually pretty cost effective when you look at how expensive some of these Blichmann/B3 3 vessel builds and sculptures are, and for the folks who also have a 10 gallon fermenter, you can bet they spent at LEAST $3000 for a system and conical altogether.

MeetsCriteria

Well-Known Member

Have you noticed it has a lot of trub on use sides after a boil?

Also any idea of what type of efficiency you're getting?

Well, I haven't calc'd brewhouse efficiency. My efficiency after the mash has been lower than I'm used to, which I think has to do with running off too fast (obviously this has nothing to do with the 3-in-1).

If I had to gestalt it, i'd say my brewhouse efficiency has gone up a fair bit as transfer losses are definitely less. After I cool, the grub gets dumped from the conical (before pitching yeast). Probably is just 32 oz worth of wort / trub give or take.

There is some trub on the sides, and I imagine it is no problem. But I have felt compelled to wipe it off as best as possible after 30 min of boiling or so, just because I could.

What style of hops do you use in your boil, leaf or pellet? Do you use the hop baskets that Brewha sells?

I use pellet hops and plan on throwing them directly in the boil. My thought is I should be able to drop them out of the bottom drain after the boil is complete. My only concern is clogging that port with compacted hop matter.

Also, have you tried recirculating during chilling with the racking arm that you installed? I'm thinking it would speed up the chilling process significantly.

I use pellet hops and plan on throwing them directly in the boil. My thought is I should be able to drop them out of the bottom drain after the boil is complete. My only concern is clogging that port with compacted hop matter.

Also, have you tried recirculating during chilling with the racking arm that you installed? I'm thinking it would speed up the chilling process significantly.

MeetsCriteria

Well-Known Member

So far I've just used pellet. The first batch, I did exactly as you described...just put them in the boil and dumped trub after cooling.

I think that with the hops plus the coagulated protein / trub, I could see how it could plug the system. It took a minute (at least it felt like a minute) or so for the plug to "break free" when I was ready to dump it. There was a gelatinous plug that had formed...The irish moss may have contributed to this?

The second batch I used a hop spider:

http://www.stainlessbrewing.com/Hop-Spider-with-seam-welds_p_158.html

It was the 6 5/8" version. That worked great. Big enough to use for multiple hop additions. Whether one used a hop spider vs. what is offered by brewha, that's the only way I could see using whole hops.

No "plug" with that batch. Trub dump was easy.

I also wondered with the first batch how much of the hops just went to the bottom of the valve / cone vs. stayed aloft in the boil, and how that did / did not contribute to hop utilization. Beer was great, so probably ok...

I have thought of recirculating to chill, and I bet it would be somewhat faster. It slightly complicates the process, introduces an extra sanitation step, and would contribute to less brewhouse efficiency...all counter to why I got the 3-in-1 in the first place. But I have considered doing such, say if I was going to recirculate using a hop back or something like that.

Knowing how long the commercial guys whirlpool, I'm not worried about the 20-30 min to cool it as is...and the fact that sanitation becomes a non-issue is very compelling. I don't miss those last few steps of my old brew process in the least!

I think that with the hops plus the coagulated protein / trub, I could see how it could plug the system. It took a minute (at least it felt like a minute) or so for the plug to "break free" when I was ready to dump it. There was a gelatinous plug that had formed...The irish moss may have contributed to this?

The second batch I used a hop spider:

http://www.stainlessbrewing.com/Hop-Spider-with-seam-welds_p_158.html

It was the 6 5/8" version. That worked great. Big enough to use for multiple hop additions. Whether one used a hop spider vs. what is offered by brewha, that's the only way I could see using whole hops.

No "plug" with that batch. Trub dump was easy.

I also wondered with the first batch how much of the hops just went to the bottom of the valve / cone vs. stayed aloft in the boil, and how that did / did not contribute to hop utilization. Beer was great, so probably ok...

I have thought of recirculating to chill, and I bet it would be somewhat faster. It slightly complicates the process, introduces an extra sanitation step, and would contribute to less brewhouse efficiency...all counter to why I got the 3-in-1 in the first place. But I have considered doing such, say if I was going to recirculate using a hop back or something like that.

Knowing how long the commercial guys whirlpool, I'm not worried about the 20-30 min to cool it as is...and the fact that sanitation becomes a non-issue is very compelling. I don't miss those last few steps of my old brew process in the least!

ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

I skimmed back through this thread....did I miss any suggestions for low pressure steam? If you could boil the wort by pushing steam through the jacket WITH THE OUTLET COMPLETELY UNRESTRICTED, you would be able to eliminate the element. Then, you could later use the jacket for chilling and maintaining wort temps.

- Joined

- Nov 1, 2010

- Messages

- 344

- Reaction score

- 28

- Joined

- Nov 1, 2010

- Messages

- 344

- Reaction score

- 28

I skimmed back through this thread....did I miss any suggestions for low pressure steam? If you could boil the wort by pushing steam through the jacket WITH THE OUTLET COMPLETELY UNRESTRICTED, you would be able to eliminate the element. Then, you could later use the jacket for chilling and maintaining wort temps.

That actually sounds like a great idea.

Do you think the valve is responsible for the slow draining of the hop/break sludge? I've been thinking about swapping that ball valve out for a butterfly valve. The opening on the ball valve looks like it's quite restrictive compared to the opening on the triclover.

MeetsCriteria

Well-Known Member

Do you think the valve is responsible for the slow draining of the hop/break sludge? I've been thinking about swapping that ball valve out for a butterfly valve. The opening on the ball valve looks like it's quite restrictive compared to the opening on the triclover.

That's certainly possible. I have a butterfly valve (1") that I could try next time. That said, the second brew session was not a problem. It could have been the increased hop debris from not using a hop basket, and the hot break congealed in the bottom.

Still loving it but haven't had time to brew again due to work. Probably in the next week or two!

KIAKillerXJ

Well-Known Member

Man, I really, really, want the whole BIAC package. And frankly, for $2900 I still think its a smoking deal. Just need the 2900 bucks haha. It would suit my style perfectly. I already brew 10gal BIAB batches, and would love a conical. Jacketed. Pressure transfer. Electric. Not sure what else I could ask for. I don't get to brew often enough for the problem of tying up all my vessels at once, so think it would work brilliantly. And the craftsmanship just looks fantastic.

On a non jacketed fermentor something like this might be an solution to not having a heating element submerged during fermentation.

http://www.ebay.com/itm/1740mm-X-250mm-2000-Watt-220V-Silicone-Drum-Heater-WVO-Biodiesel-Tank-Barrel-55G-/131161594612?pt=LH_DefaultDomain_3&hash=item1e89d71af4

http://www.ebay.com/itm/1740mm-X-250mm-2000-Watt-220V-Silicone-Drum-Heater-WVO-Biodiesel-Tank-Barrel-55G-/131161594612?pt=LH_DefaultDomain_3&hash=item1e89d71af4

Well, I haven't seen anything on this specific topic.

I've had a 120v HERMS mash system for a over a year now but have been using propane for the boil.

Recently, I've been looking to go electric on my brew kettle. Through that search, I discovered the 3-in-1 "Boil Kettle, Jacketed Chiller, Conical Fermenter" by Brewha. I've seen nothing on the forum yet either debating its design, or any posts from early adopters. It seems amazingly promising.

Check it out:

http://brewha.co/products/3-in-1

Long story short, I decided to pull the trigger on it, so mine is "in the mail" as they say.

I'll periodically update my experiences (which are hopefully excellent) for general consumption of the community. Wish me luck!

Cheers,

Mike

Full Disclosure: I have no private or public interest in Breha or its products. My post is simply for information purposes only.

Last edited by a moderator:

or perhaps it would be possible to boil with low pressure steam through the jacket like on a steam kettle.

or you could circulate heated mineral oil to avoid any pressure, and use the same oil to chill during fermentation

http://www.multitherm.com/multitherm-pg-1.html

or you could circulate heated mineral oil to avoid any pressure, and use the same oil to chill during fermentation

http://www.multitherm.com/multitherm-pg-1.html

I ended up upgrading to the BIAC instead of just the 3-in-1. Brewha has upped the size of the conical from 67 liters to 80, allowing you to brew a 10g batch in the single vessel. I can't wait to get this thing in my hands.

MeetsCriteria

Well-Known Member

I ended up upgrading to the BIAC instead of just the 3-in-1. Brewha has upped the size of the conical from 67 liters to 80, allowing you to brew a 10g batch in the single vessel. I can't wait to get this thing in my hands.

It just keeps getting better and better! Can't wait to see pics / hear about results!

MeetsCriteria

Well-Known Member

Finally found time to upload pics regarding the elements I've tried.

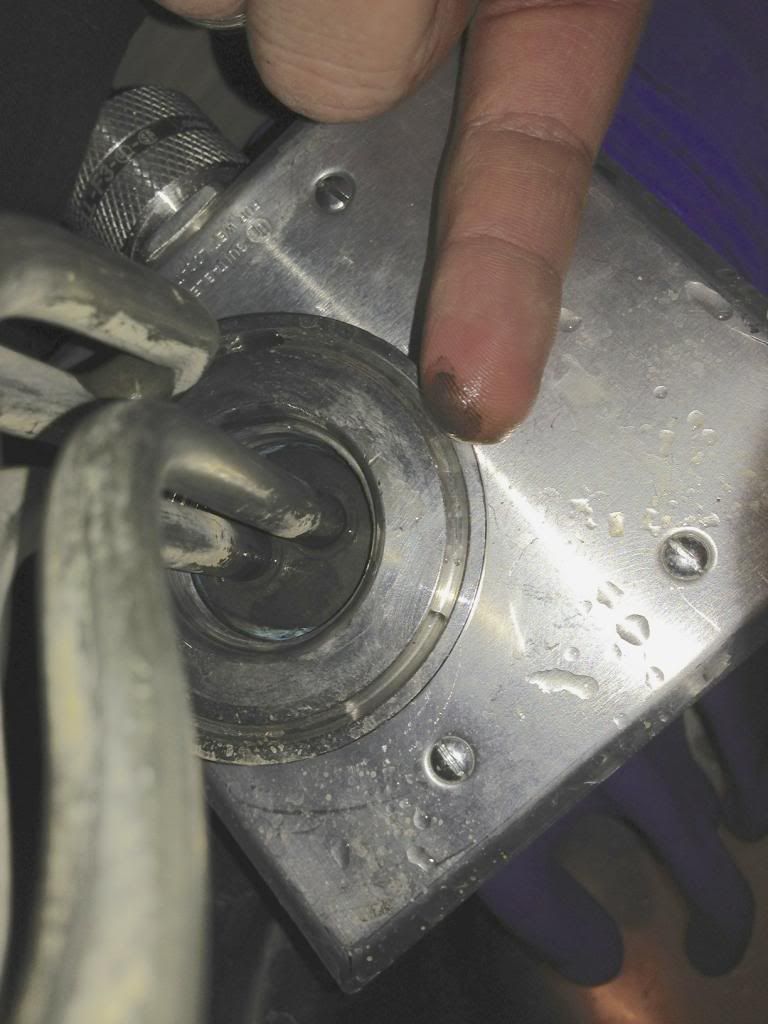

After first brew, the base of the first element did have some bit of oxidation, as I noted earlier. Here's what that looked like:

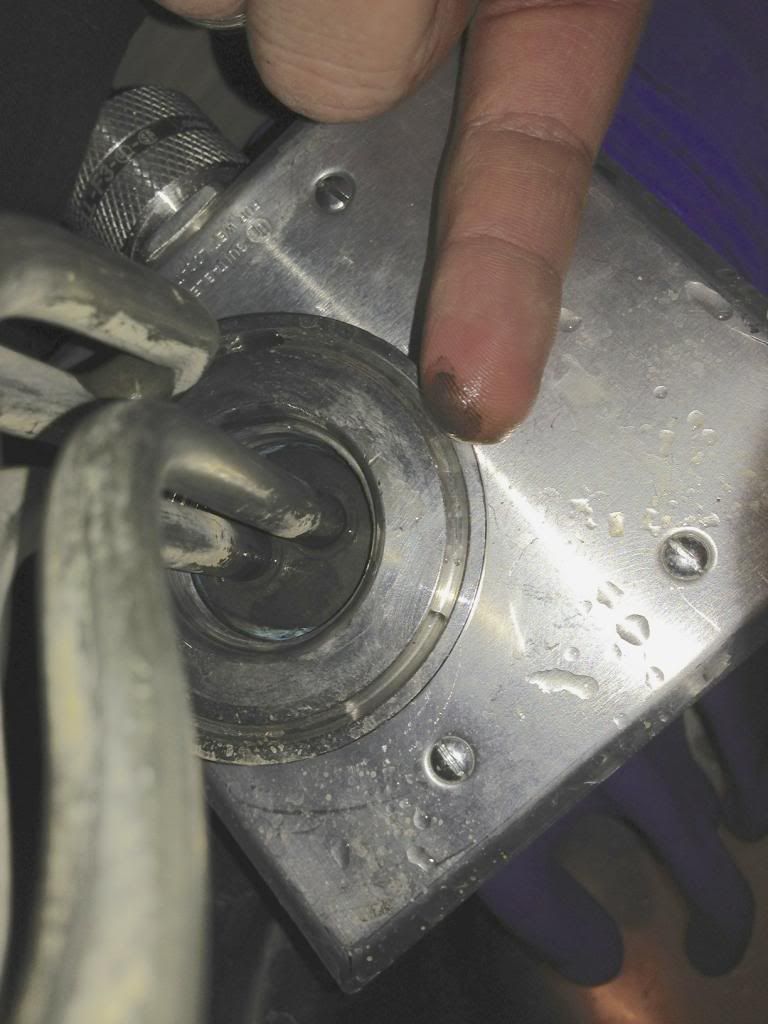

The upgraded SS base element after the first batch looked like new, as expected (it IS stainless steel after all):

So, no flys on the SS base element for sure!

After first brew, the base of the first element did have some bit of oxidation, as I noted earlier. Here's what that looked like:

The upgraded SS base element after the first batch looked like new, as expected (it IS stainless steel after all):

So, no flys on the SS base element for sure!

MeetsCriteria

Well-Known Member

The racking arm is a nice addition and highly rec'd.

This is a great idea. Thanks MeetsCriteria for starting this thread.

BIAB with a 10 gallon system then 2 weeks in the conical and off to bottle/kegging.

mmmmm lots of time left over for the important work of sampling

BIAB with a 10 gallon system then 2 weeks in the conical and off to bottle/kegging.

mmmmm lots of time left over for the important work of sampling

Similar threads

- Replies

- 0

- Views

- 483

- Replies

- 1

- Views

- 686

- Locked

- Replies

- 15

- Views

- 3K

- Replies

- 17

- Views

- 3K

- Replies

- 7

- Views

- 2K