joutlaw

Well-Known Member

Hey Guys,

We have been in our new house for a year and I wished I had ran 220v to the garage during construction. I have a 15 gallon 3 vessel system and I'm interested in RIMS/HERMS, but would likely still use propane for boiling. The garage has 110v 20A GFCI in place and I could likely use that for RIMS. However, I am not sure if I could do step mashes and ramp up the 10 gallon batches effectively. I also want to have the option for going all electric in the future.

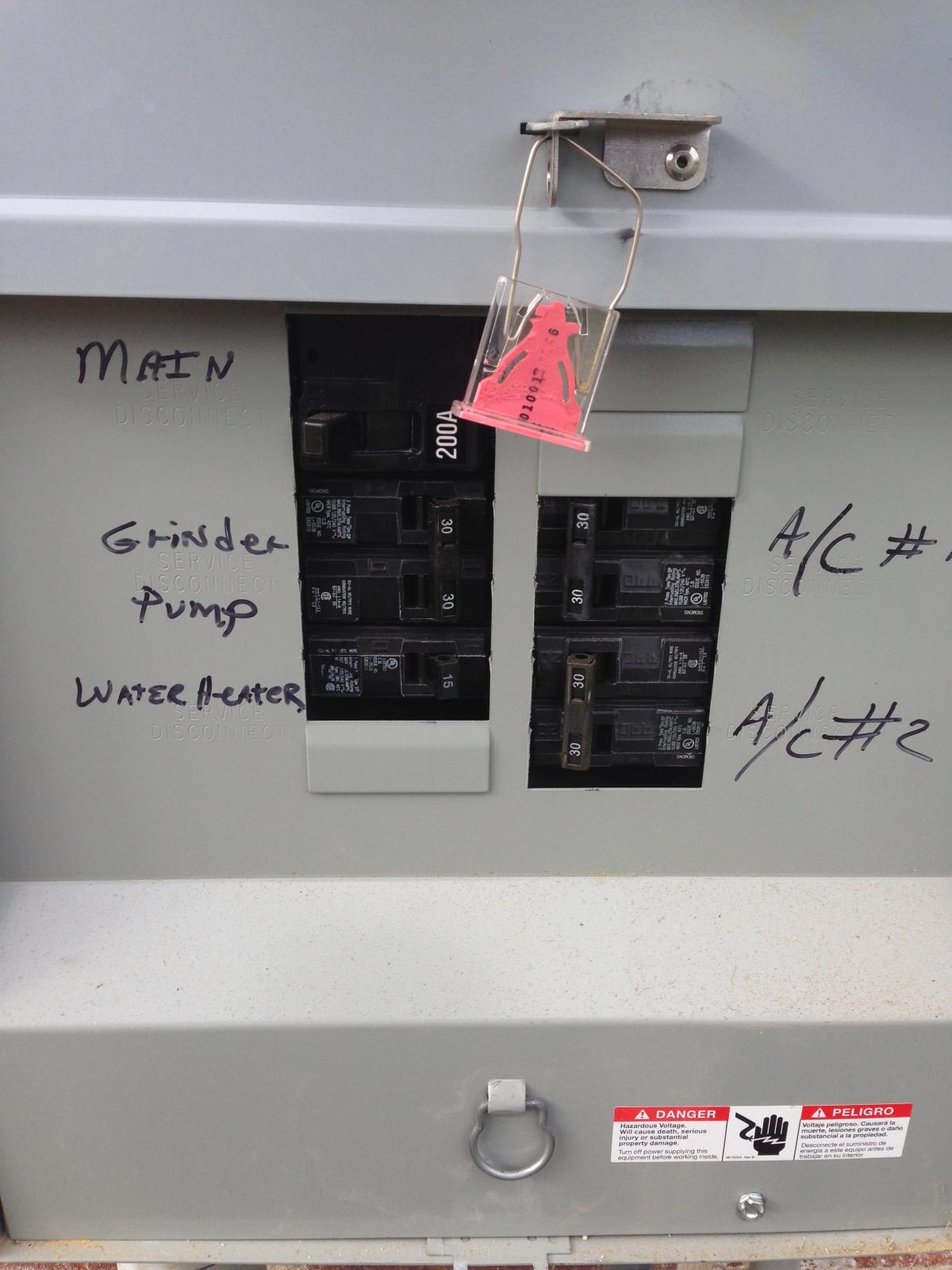

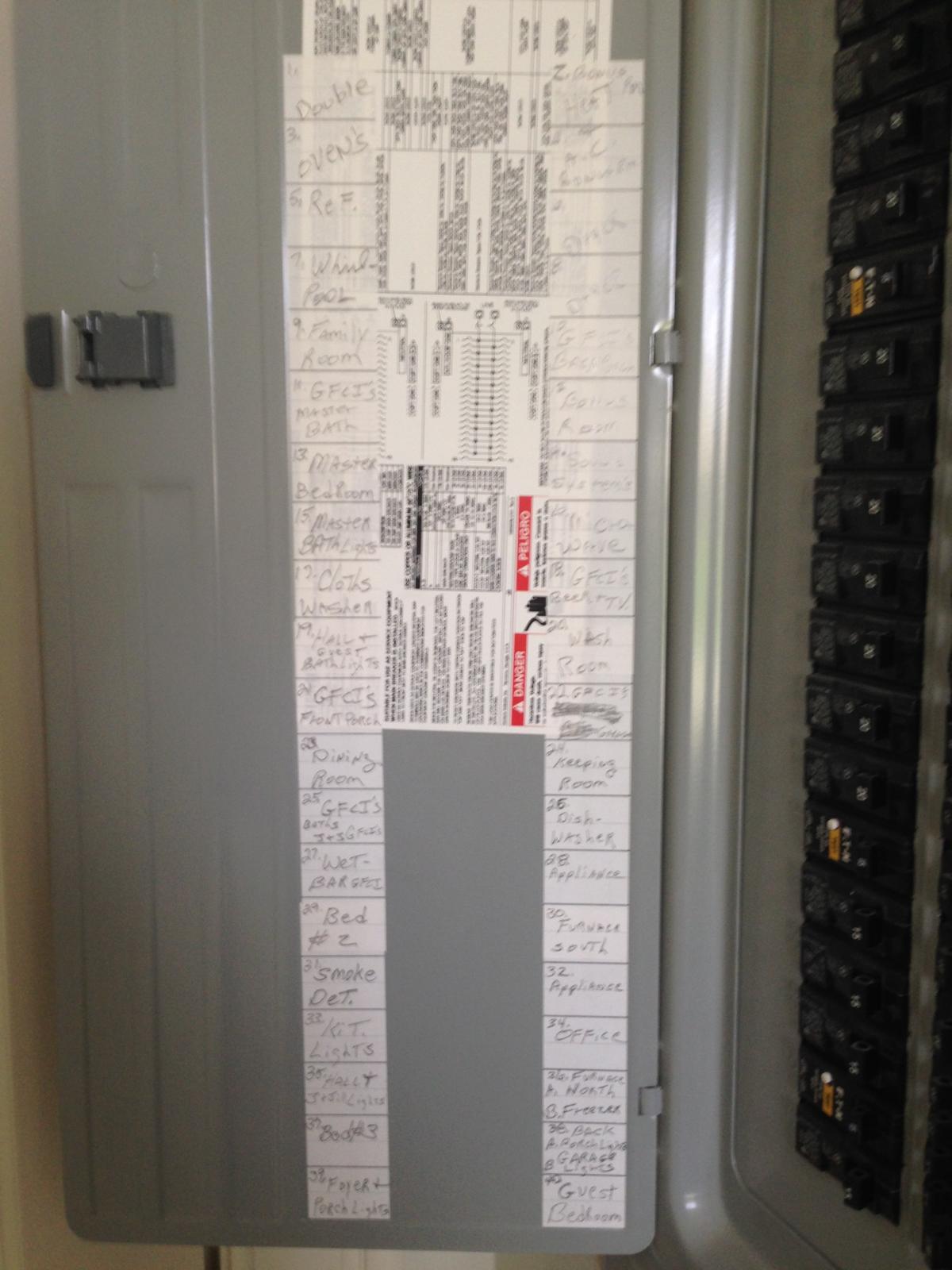

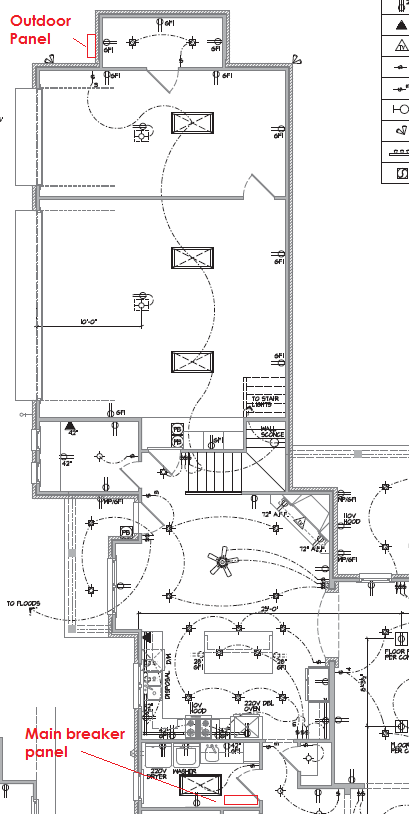

We have a main panel outside and then a sub panel that is used by our bonus room's A/C and electric heat units. It appears from looking in the attic that the sub panel is fed by SER cable coming from 200A main breaker panel in our laundry room.

Being that the outdoor sub panel is on the exterior wall of garage, could a 220v line be fed off that panel? I'm thinking the wiring expense would be much less if so.

We have been in our new house for a year and I wished I had ran 220v to the garage during construction. I have a 15 gallon 3 vessel system and I'm interested in RIMS/HERMS, but would likely still use propane for boiling. The garage has 110v 20A GFCI in place and I could likely use that for RIMS. However, I am not sure if I could do step mashes and ramp up the 10 gallon batches effectively. I also want to have the option for going all electric in the future.

We have a main panel outside and then a sub panel that is used by our bonus room's A/C and electric heat units. It appears from looking in the attic that the sub panel is fed by SER cable coming from 200A main breaker panel in our laundry room.

Being that the outdoor sub panel is on the exterior wall of garage, could a 220v line be fed off that panel? I'm thinking the wiring expense would be much less if so.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)