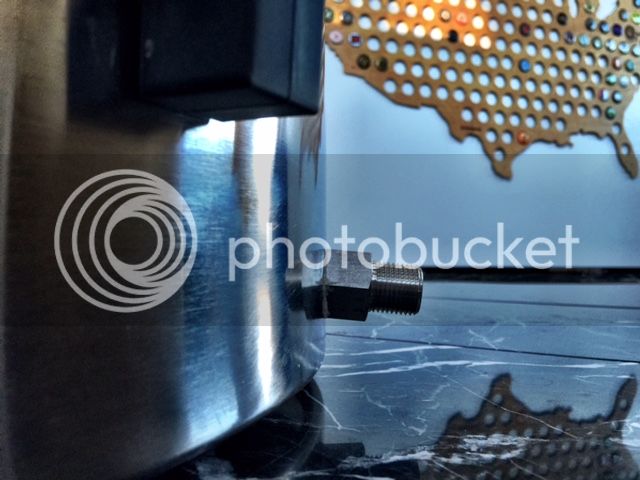

The purpose of a manometer in a mash tun application is to monitor the pressure differential both above and below the false bottom. The manometer offers a visual representation of how fast you are drawing wort through the grain bed, based on the difference in level between the two tubes. When wort is run-off quickly it creates a pressure differential within the grist, and can actually compact the grain bed, typically resulting in a stuck sparge. While grists consisting of 100% barley are rarely at risk; wheat, rye or oat blends will compact more easily because they do not have a comparably rigid grain husk. While lautering, if you observe the difference between the upper and lower manometer tubes approaching 3⁄4 inch, you are running-off too quickly. Ideally, the difference should be zero to 1⁄4 of an inch.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)