- Joined

- Jan 3, 2020

- Messages

- 3,275

- Reaction score

- 3,977

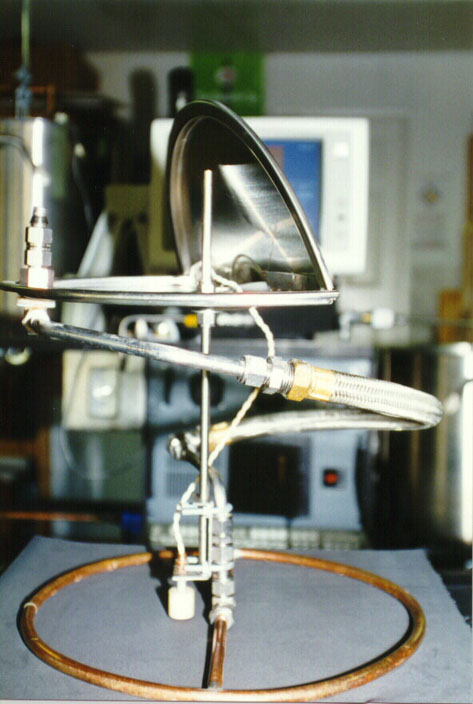

I have an electric keggle with hopstopper. Hopstopper is 2-3 years old? I have no need to recirculate during the boil. For a 6 gallon batch, anything over 50% power is plenty virgorous to where I have no need to even stir. Similar for 10 gallons, but maybe a little more power.

I also whirlpool hops for 20-30 minutes through another port not connected to my hopstopper using a Spike Flow, no problems with hazies. Temps 155-175F. Only problem Is I recently discovered it requires a shorter period for breaking down the pump for deep cleaning. I normally CIP every brew for 30 minutes at 150F. I might have been beyond my deep cleaning interval but I don't think so and the pump was gunky. Could have been I didn't use the correct amount of PBW. Spike claims the propellor chews through hops. Whole hops I'd probably still put in a spider, mostly pellets these days.

Before the hopstopper, nearly all trub went in the fermenter with a side pickup. (I would tilt the keggle at the end) With the hopstopper some trub I think settles with the hops. Really can't tell how much. Pickup tube is neary centered but floating as the hopstopper bottom is flat and the end of the pickup tube touches the hopstopper bottom.

I also whirlpool hops for 20-30 minutes through another port not connected to my hopstopper using a Spike Flow, no problems with hazies. Temps 155-175F. Only problem Is I recently discovered it requires a shorter period for breaking down the pump for deep cleaning. I normally CIP every brew for 30 minutes at 150F. I might have been beyond my deep cleaning interval but I don't think so and the pump was gunky. Could have been I didn't use the correct amount of PBW. Spike claims the propellor chews through hops. Whole hops I'd probably still put in a spider, mostly pellets these days.

Before the hopstopper, nearly all trub went in the fermenter with a side pickup. (I would tilt the keggle at the end) With the hopstopper some trub I think settles with the hops. Really can't tell how much. Pickup tube is neary centered but floating as the hopstopper bottom is flat and the end of the pickup tube touches the hopstopper bottom.

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)