Mdunlop4428

Active Member

- Joined

- May 6, 2014

- Messages

- 30

- Reaction score

- 3

I spent 2 years on theelectricbrewery website researching and designing and one year building my fully electric BCS controlled brewery. I also have a thread on this site. I've only brewed on this system 6 times. I'm moving to a location where I just don't have the space for my set up. I'm hesitant in listing this but know it has to be done. I'm going to do the best that I can to list everything that I'm selling. I'm not interested in parting this out. What I'm offering is an entire set up that needs nothing.

Here it goes:

View attachment 382739

View attachment 382741

View attachment 382742

View attachment 382743

View attachment 382744

View attachment 382745

View attachment 382746

View attachment 382747

This link is to my Photobucket. Make sure to look at my bucket and recent downloads. If there is something specific you want a picture of let me know. I have hundreds of pictures of my system and the build process

http://s1078.photobucket.com/user/mikedunlop1ndunlop4428/library/?sort=3&page=1

20 gallon stout tanks- HLC has custom 5/8 SS coil, sight gauge, Thermal well, TC connector for electric heating element. temperature probe communicates to the BCS from the tank output line

MT 20 gallon and has false bottom with bottom outlet and temperature probe on the output line of the tank reporting to BCS

BC 20 gallon with tangible inlet and thermal well probe reporting directly to BCS and TC connector for heating element for professional and clean install

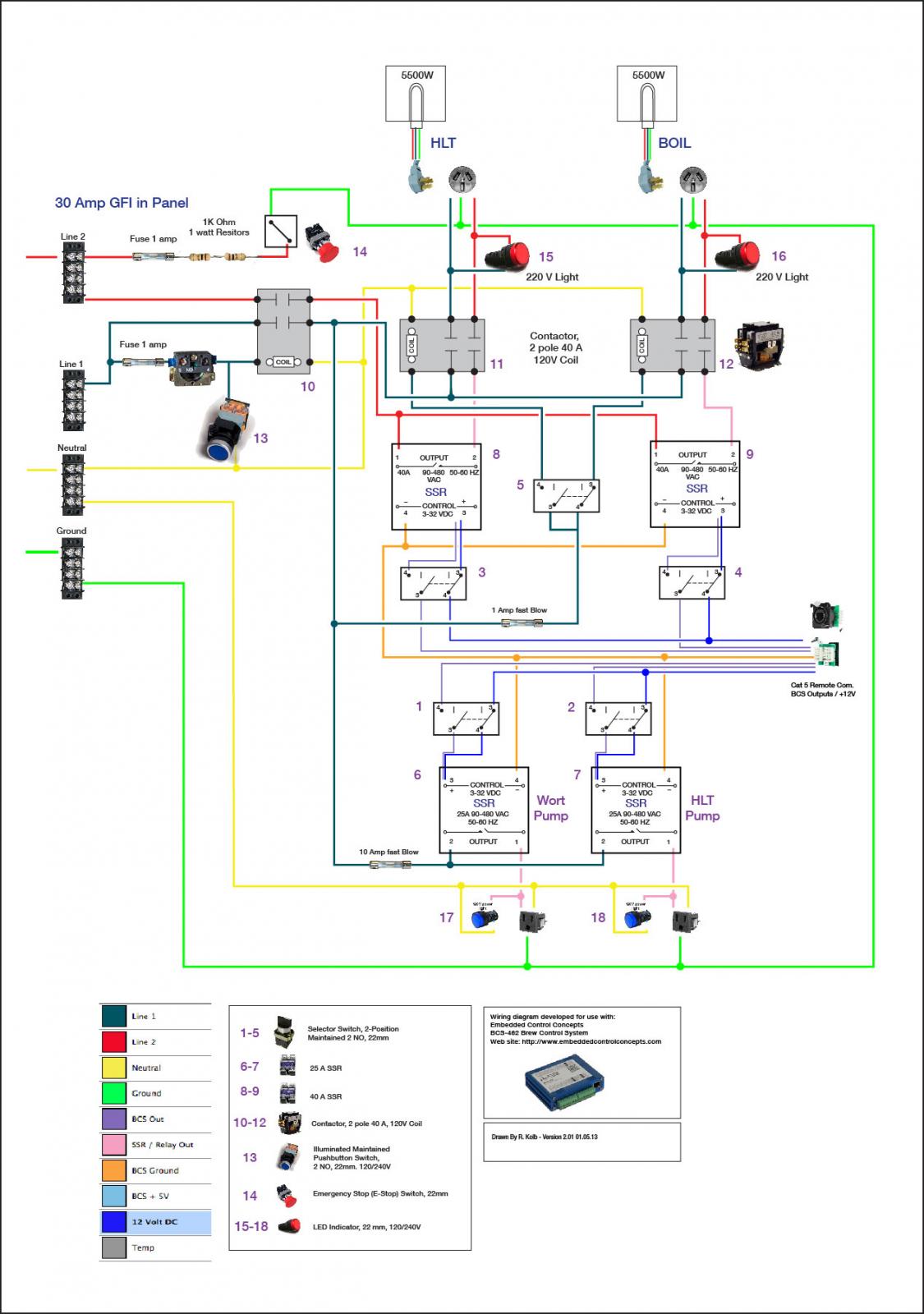

30 amp panel that runs in automatic or manual mode with the BCS controller. BCS has processes to automate the brewing process from start to finish. Motorized valves control the flow and movement from the beginning of brew day where water enters the HLC, transfers to mash tun, circulating and strike in, to BC, sterilizing the counter flow chiller and finally through the counter flow chiller and oxygenation through a diffuse stone built into the plumbing. Panel can also run heating elements and pumps in manual if desired. Emergency stop and keyed power control. This panel was copied by a diagram I found on Homebrewtalk that PJ designed. I have the schematic to share is desired. All power and input cables are built and protected per Kal's design

2 Chugger SS pumps and one spare motor on the self

7 motorized ball valves with TC fitting. BCS controlled to automate the enter process

BCS panel houses the controller and power supply. My system has processes built to control my the brewing process, Glycol chiller, and keg frig all through an I-pad or PC. I'm using cat 5 wire to communicate to the respective temperature probes and also to send a 5v control signal to a power relay that runs the keg and glycol chiller power.

2 SS Tables. 1 60 inches and 1 48 inches

1 24x24 SS commercial sink with drip tray and commercial spray wand.

1 custom exhaust hood driven by the identical fan Kal uses including the ARI-Speed controller

1 Copper Counter flow chiller with temperature of its output reporting to the BCS

1 TC oxygen stone on the output side of the CF chiller.

1 oxygen tank and regulator

4 glass carboy's

1 8 tap Micromatic Glycol cooled draft tower. Two Stout faucets, same as Kal's

1 SS Micromatic Drip tray with glass rinse option same as Kal's

8 product supply truck line with glycol tubes

keg frig holds 8 kegs, and is plumbed to customize keg pressures. new chest freezer with 6 inch laminated collar and temperature probe reporting to BCS and controlling a power relay from the custom process

1 beer gas tank and regulator with tank pressure runs two kegs at the same pressure for dark beers

1 20lb Co2 tank and regulator with two way output and tank guage

11 kegs and half were purchased new. All have new seals and o-rings

Glycol chiller is a dehumidifier and cooler with RV fluid which operates very efficiently. It is fully automated by BCS. A pump keeps my trunk line and draft tower at the perfect temperature for the perfect poor. Temperature probe and power relay runs from a process designed within the BCS and can be fully customized

I have tons of extra parts.

4 motorized ball valves

4 BCS temperature probes

2 extra faucets for Micomatic tower

oxygen fill connector for tank

Tons of salts

Keg o-rings and extra parts

extra chugger motor

TC fittings

cat 5 connections

Deco Brother scale

2 in 2 roller SS monster mill

Nuova II stir plate and 2000 ml flask for starters

chemical, cleaners, sterilizers, tools...

1 three way Taprite CO2 manifold allows me to have three keg with customs pressure and three kegs with the same pressure

Make me a reasonable offer. Located in Wisconsin [email protected] or [email protected] or 920-750-1734

This system has been such a joy to use and I love the automation and interface of the BCS. If you want, I can also provide screen shots of the many BCS processes I built and how they interface with the brewing, chilling, fermentation, and serving process.

Here it goes:

View attachment 382739

View attachment 382741

View attachment 382742

View attachment 382743

View attachment 382744

View attachment 382745

View attachment 382746

View attachment 382747

This link is to my Photobucket. Make sure to look at my bucket and recent downloads. If there is something specific you want a picture of let me know. I have hundreds of pictures of my system and the build process

http://s1078.photobucket.com/user/mikedunlop1ndunlop4428/library/?sort=3&page=1

20 gallon stout tanks- HLC has custom 5/8 SS coil, sight gauge, Thermal well, TC connector for electric heating element. temperature probe communicates to the BCS from the tank output line

MT 20 gallon and has false bottom with bottom outlet and temperature probe on the output line of the tank reporting to BCS

BC 20 gallon with tangible inlet and thermal well probe reporting directly to BCS and TC connector for heating element for professional and clean install

30 amp panel that runs in automatic or manual mode with the BCS controller. BCS has processes to automate the brewing process from start to finish. Motorized valves control the flow and movement from the beginning of brew day where water enters the HLC, transfers to mash tun, circulating and strike in, to BC, sterilizing the counter flow chiller and finally through the counter flow chiller and oxygenation through a diffuse stone built into the plumbing. Panel can also run heating elements and pumps in manual if desired. Emergency stop and keyed power control. This panel was copied by a diagram I found on Homebrewtalk that PJ designed. I have the schematic to share is desired. All power and input cables are built and protected per Kal's design

2 Chugger SS pumps and one spare motor on the self

7 motorized ball valves with TC fitting. BCS controlled to automate the enter process

BCS panel houses the controller and power supply. My system has processes built to control my the brewing process, Glycol chiller, and keg frig all through an I-pad or PC. I'm using cat 5 wire to communicate to the respective temperature probes and also to send a 5v control signal to a power relay that runs the keg and glycol chiller power.

2 SS Tables. 1 60 inches and 1 48 inches

1 24x24 SS commercial sink with drip tray and commercial spray wand.

1 custom exhaust hood driven by the identical fan Kal uses including the ARI-Speed controller

1 Copper Counter flow chiller with temperature of its output reporting to the BCS

1 TC oxygen stone on the output side of the CF chiller.

1 oxygen tank and regulator

4 glass carboy's

1 8 tap Micromatic Glycol cooled draft tower. Two Stout faucets, same as Kal's

1 SS Micromatic Drip tray with glass rinse option same as Kal's

8 product supply truck line with glycol tubes

keg frig holds 8 kegs, and is plumbed to customize keg pressures. new chest freezer with 6 inch laminated collar and temperature probe reporting to BCS and controlling a power relay from the custom process

1 beer gas tank and regulator with tank pressure runs two kegs at the same pressure for dark beers

1 20lb Co2 tank and regulator with two way output and tank guage

11 kegs and half were purchased new. All have new seals and o-rings

Glycol chiller is a dehumidifier and cooler with RV fluid which operates very efficiently. It is fully automated by BCS. A pump keeps my trunk line and draft tower at the perfect temperature for the perfect poor. Temperature probe and power relay runs from a process designed within the BCS and can be fully customized

I have tons of extra parts.

4 motorized ball valves

4 BCS temperature probes

2 extra faucets for Micomatic tower

oxygen fill connector for tank

Tons of salts

Keg o-rings and extra parts

extra chugger motor

TC fittings

cat 5 connections

Deco Brother scale

2 in 2 roller SS monster mill

Nuova II stir plate and 2000 ml flask for starters

chemical, cleaners, sterilizers, tools...

1 three way Taprite CO2 manifold allows me to have three keg with customs pressure and three kegs with the same pressure

Make me a reasonable offer. Located in Wisconsin [email protected] or [email protected] or 920-750-1734

This system has been such a joy to use and I love the automation and interface of the BCS. If you want, I can also provide screen shots of the many BCS processes I built and how they interface with the brewing, chilling, fermentation, and serving process.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)