You can also silver braze stainless. Decent fillet joints should be plenty strong.

OK, as usual, going gonzo to pick up what I can. So been watching Welding tips - 5 part series on Mig alone. Thanks, Sandy, that guy's awesome and this is really fascinating.

I also watched Weld Fever's Mig welding square tubing, and learned a lot, in just one video.

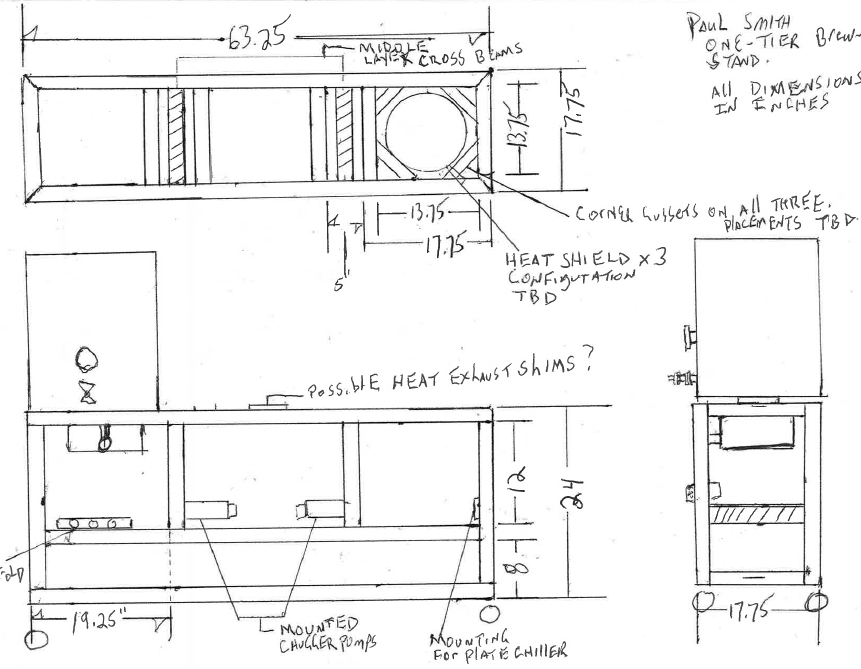

So, in other words, don't laugh at the questions, guys. Ong, Fever makes the point that each joint surface has its own character, e.g., flared bevel where the rolled side meets the straight cut? And I think he seemed to be saying that along these edges, you need to slow it down and fill in more, because of the less-than-perfect match of the surfaces; right? Then the fillet and butt welds. Take this as a total noob trying to keep it straight, not questioning expertise. The reason I'm asking is just to double check if something like silver brazing is strong enough, given this? Or am I overthinking this?

Now - let me tie your suggestion, Ong, into a second thing. I fear I'll truly screw this all up. Even though it's mig, just because it's stainless, and I've never dealt with shielding gases before. If brazing can do it, man, I'd feel better about that.

The final thing - first time I built the rig, that 1 x 1 mild, I had a brewing supplier who was happy to rent to me at a substantial break, in trade for beer. This time, I've got zip in the way of equipment and am not sure I can rent all the incidentals. I know myself and know I could easily go nuts on yet another new thing, but SWMBO I think, would finally tilt. And if what I just read was right - with examples of Praxair charging couple hundred for the cylinder, and 350-400 for the gas (cheapest example, Airgas for a total of $240, cylinder inclusive), well...I wonder if I'm being ridiculous in basically starting to acquire a welding setup, when I'm lousy at it, and can easily outspend doing this compared to just finding a more responsive professional.

If I knew I could rent everything, practice enough to not make it look like modern art, and do it, all in, at a cost that didn't swamp my just paying a pro, then the bug in me is definitely lit. Seriously, always wanted to learn to weld and I know MIG is the easiest of all of them as a way in (right?). But so far, it's not looking good. Am I making any sense?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)