Need help checking my work

First brew attemt, don't have ro access, tap water not a viable choice for me. Starting with distilled and already have all the salts so I'm not Not going to use them.

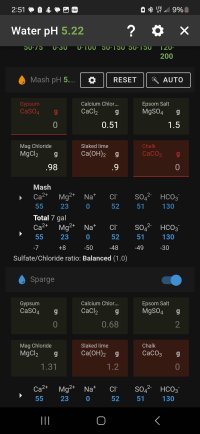

This is what I have so far

0.49 g — Chalk (CaCO3) — Mash

0.79 g — Epsom Salt (MgSO4) — Mash

0.49 g — Gypsum (CaSO4) — Mash

8 ml — Lactic Acid 80% — Mash

0.79 g — Magnesium Chloride (MgCl2) — Mash

0.49 g — Slaked Lime (Ca(OH)2) — Mash

0.83 g — Calcium Chloride (CaCl2) — Sparge

0.65 g — Chalk (CaCO3) — Sparge

1.05 g — Epsom Salt (MgSO4) — Sparge

0.65 g — Gypsum (CaSO4) — Sparge

2.54 ml — Lactic Acid 80% — Sparge

1.05 g — Magnesium Chloride (MgCl2) — Sparge

0.65 g — Slaked Lime (Ca(OH)2) — Sparge

recipe

71% efficiency

Batch Volume: 4.5 gal

Boil Time: 60 min

Mash Water: 5.16 gal

Sparge Water: 1.55 gal

Total Water: 6.72 gal

Boil Volume: 5.76 gal

Pre-Boil Gravity: 1.064

Vitals

Original Gravity: 1.074

Final Gravity: 1.017

IBU (Tinseth): 17

BU/GU: 0.23

Color: 7.6 SRM

Mash

Strike Temp — 207.9 °F

protien — 99 °F — 30 min

ferulic rest — 112 °F — 40 min

sacch' rest — 145 °F — 60 min

after — 150 °F — 30 min

Malts (12 lb 6.9 oz)

5 lb 10.7 oz (45.6%) — Cargill Wheat White — Grain — 2.7 °L — Mash — 90 min

3 lb 13.4 oz (30.9%) — Pilsner Malt — Grain — 1.8 °L — Mash — 90 min

2 lb 14.9 oz (23.6%) — Munich Malt, Germany — Grain — 7.6 °L — Mash — 90 min

Hops (0.36 oz)

0.36 oz (17 IBU) — Magnum 12% — First Wort

First brew attemt, don't have ro access, tap water not a viable choice for me. Starting with distilled and already have all the salts so I'm not Not going to use them.

This is what I have so far

Miscs

0.62 g — Calcium Chloride (CaCl2) — Mash0.49 g — Chalk (CaCO3) — Mash

0.79 g — Epsom Salt (MgSO4) — Mash

0.49 g — Gypsum (CaSO4) — Mash

8 ml — Lactic Acid 80% — Mash

0.79 g — Magnesium Chloride (MgCl2) — Mash

0.49 g — Slaked Lime (Ca(OH)2) — Mash

0.83 g — Calcium Chloride (CaCl2) — Sparge

0.65 g — Chalk (CaCO3) — Sparge

1.05 g — Epsom Salt (MgSO4) — Sparge

0.65 g — Gypsum (CaSO4) — Sparge

2.54 ml — Lactic Acid 80% — Sparge

1.05 g — Magnesium Chloride (MgCl2) — Sparge

0.65 g — Slaked Lime (Ca(OH)2) — Sparge

recipe

71% efficiency

Batch Volume: 4.5 gal

Boil Time: 60 min

Mash Water: 5.16 gal

Sparge Water: 1.55 gal

Total Water: 6.72 gal

Boil Volume: 5.76 gal

Pre-Boil Gravity: 1.064

Vitals

Original Gravity: 1.074

Final Gravity: 1.017

IBU (Tinseth): 17

BU/GU: 0.23

Color: 7.6 SRM

Mash

Strike Temp — 207.9 °F

protien — 99 °F — 30 min

ferulic rest — 112 °F — 40 min

sacch' rest — 145 °F — 60 min

after — 150 °F — 30 min

Malts (12 lb 6.9 oz)

5 lb 10.7 oz (45.6%) — Cargill Wheat White — Grain — 2.7 °L — Mash — 90 min

3 lb 13.4 oz (30.9%) — Pilsner Malt — Grain — 1.8 °L — Mash — 90 min

2 lb 14.9 oz (23.6%) — Munich Malt, Germany — Grain — 7.6 °L — Mash — 90 min

Hops (0.36 oz)

0.36 oz (17 IBU) — Magnum 12% — First Wort

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)