ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

I think I'm gonna do it.

I think I'm gonna do it.  God help me if it breaks

God help me if it breaks

I think I'm gonna do it.

I think I'm gonna do it.  God help me if it breaks

God help me if it breaks I think I'm gonna do it.

God help me if it breaks

I think I'll restrict the flow into the chamber vs on the output so pressure can't build.

Sawdustguy, did you order from KLGstainless.com or KLG's ebay store? Or is there a difference?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Guy-

What brand is your element? Does it have NPT or NPS threads? I'm ordering my sightglass and I wonder if I'll be okay threading a 4500-5500w LD element into a 1" FPT triclover adapter.

I've also considered buying a 1.5" FPT triclover adapter, then JB welding the element into a bushing. Then I could screw the element in/out as intended without worrying about damaging threads.

Alternatively (but it could be a PITA) I would buy a 2" triclover endcap and drill it out to 1". Then I could add the element with a weldless setup.

Steve,

My element has a 1" NPS thread so I purchased a 1.5" Tri-Clover to 1" NPT adapter. You simply need to make use of the washer that comes with the element. The NPS will thread into a NPT with no caveat.

Oh. I thought it would be a case of grinding threads, etc. So you're saying the o-ring will provide a good seal if you can get it tight enough.

Good looking out...guess it's time to spend yet some more money. Man, it adds up, doesn't it?

I refuse to pay $179 for this, but someone else might pony up.

I bet the element doesn't hit the sides in theirs.

Sorry ScubaSteve, it was to easy.

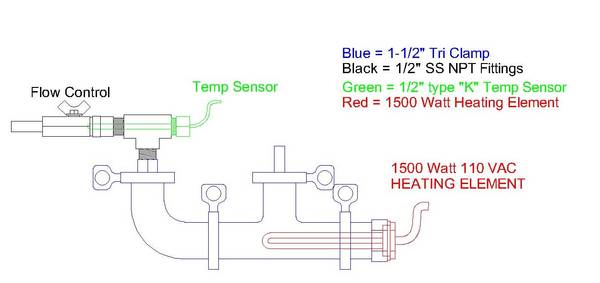

I belive the 220vac heating element is a lot longer than the 110v and would not work in this situation.Wurz

Do you think that a 220V element would work in the single tee elbow combo? I am guessing that the longer 22v 5500W element might not fit in your tube.

Did you go all SS with the temp probe section?

What kinda fasteners did u use to on the tee? Those look like they work well

Do those fasteners allow you to easily remove the tubing to clean it? Thats what I'm really after.

Is your temp probe threaded into a bushing?

I have been following his thread, that is what inspired me to make my rims tube. see below for pics.

I used u bolts to hold my rims tube down but they don't work that well. My tube is top heavy so it always wants to rotate down but I think i figured out a solution. If i can find some rubber I will put it between the rims tube and the u bolts which will create friction and in the end preventing the tube from rotating down. Regardless, I should come up with a different method for ease of disconnecting and cleaning. Right now it's going to be a main to remove it.

I have been following his thread, that is what inspired me to make my rims tube. see below for pics.