Bretso

Member

- Joined

- May 1, 2020

- Messages

- 8

- Reaction score

- 2

Hello all. Just getting started and set up.

Brewing seems like a great hobby while we're all trapped at home.

I have tried two different one gallon IPA kits from Brooklyn Brew Shop.

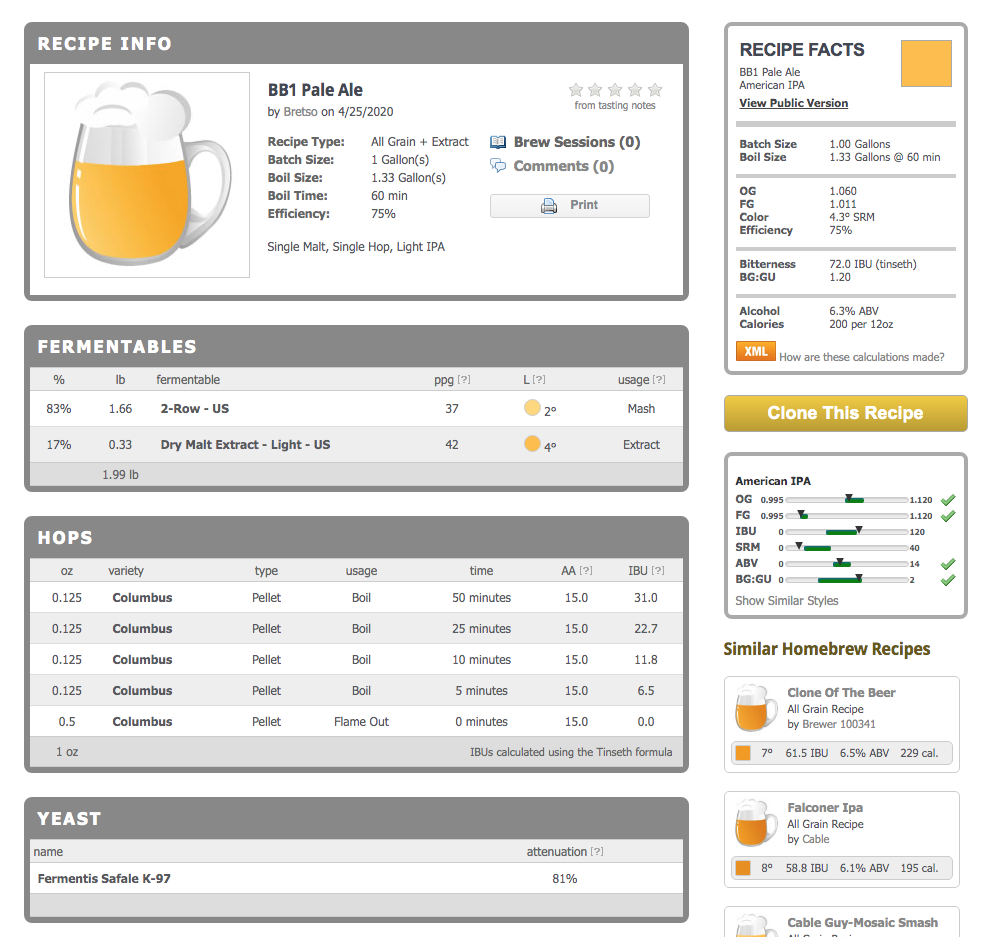

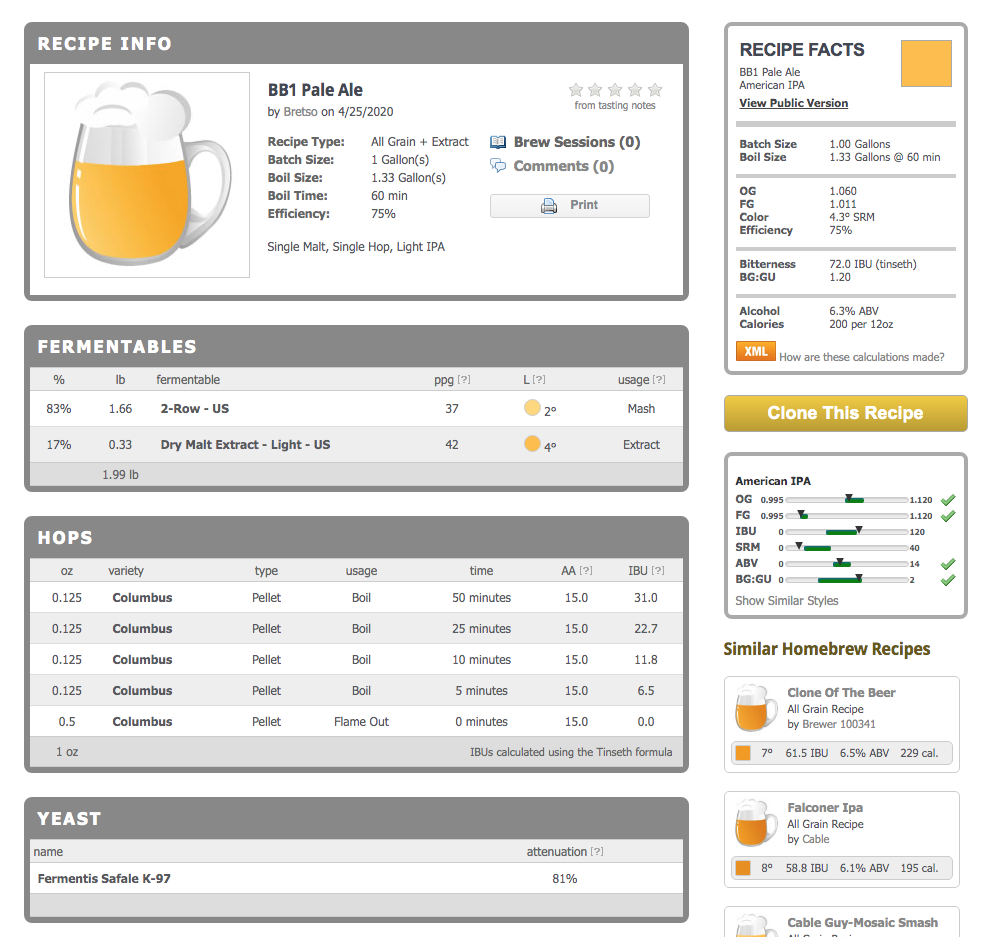

Their recipes seem simple enough so I plugged in some bulk ingredients in a recipe builder so I can try my first truly homemade beer.

How do you think this one will turn out?

(Edit: I did this in a Proper recipe builder as well - Brewer's Friend link)

Any advice is appreciated.

Brewing seems like a great hobby while we're all trapped at home.

I have tried two different one gallon IPA kits from Brooklyn Brew Shop.

Their recipes seem simple enough so I plugged in some bulk ingredients in a recipe builder so I can try my first truly homemade beer.

How do you think this one will turn out?

(Edit: I did this in a Proper recipe builder as well - Brewer's Friend link)

Any advice is appreciated.

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)