alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

Hi!

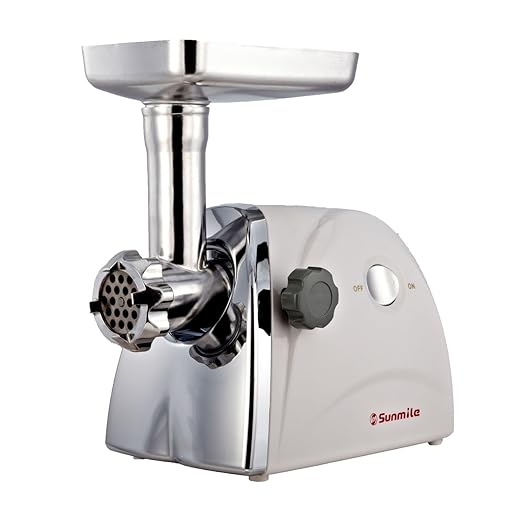

There are a lot of options when it comes to malt mills. I myself own a monster mill three roller that I motorized with the motor from a cheap meat grinder. It works very well, so I really have no reason to complain. Except...

Even though my setup would be considered 'compact' comparing to some of the sheave setups around, I still think it is too big and too heavy. I'd like cleanup to be easier.

Reading threads about mills, there seems to be a lot of talk about optimal RPM and throughput. Personally I don't mind if it is slow as <insert random four letter word>, as long as it is compact, light and still produces a decent crush. If I don't need to stand there and hold a drill or whatever, taking an hour to crush a 10 pounds would be fine for me. Why the obsession with a speedy crush? Brewing is not for the inpatient anyway. Slower (lower RPM) means a smaller motor would still produce a lot of torque.

My ideal mill, would probably look something like the old phil mill, but with a connector that fits straight into a meat grinder. You know, like an accessory to that model. It could easily be removed and cleaned. If i had the tools, know-how and time, I'd probably attempt to build it, but since I don't and since I already have a functional mill, I can only dream.

What strikes me though, is that most mills have long rollers (the mattmill kompakt seems pretty cool though) and most are not motorized or have an option to motorize (a drill seems to be the default to use). It seems most mills are 'overkill' on a homebrewing scale.

What do you guys think? What is important for you in a mill? Why aren't there any mills with rollers that are motorized and 'done', that are not semi-industrial?

There are a lot of options when it comes to malt mills. I myself own a monster mill three roller that I motorized with the motor from a cheap meat grinder. It works very well, so I really have no reason to complain. Except...

Even though my setup would be considered 'compact' comparing to some of the sheave setups around, I still think it is too big and too heavy. I'd like cleanup to be easier.

Reading threads about mills, there seems to be a lot of talk about optimal RPM and throughput. Personally I don't mind if it is slow as <insert random four letter word>, as long as it is compact, light and still produces a decent crush. If I don't need to stand there and hold a drill or whatever, taking an hour to crush a 10 pounds would be fine for me. Why the obsession with a speedy crush? Brewing is not for the inpatient anyway. Slower (lower RPM) means a smaller motor would still produce a lot of torque.

My ideal mill, would probably look something like the old phil mill, but with a connector that fits straight into a meat grinder. You know, like an accessory to that model. It could easily be removed and cleaned. If i had the tools, know-how and time, I'd probably attempt to build it, but since I don't and since I already have a functional mill, I can only dream.

What strikes me though, is that most mills have long rollers (the mattmill kompakt seems pretty cool though) and most are not motorized or have an option to motorize (a drill seems to be the default to use). It seems most mills are 'overkill' on a homebrewing scale.

What do you guys think? What is important for you in a mill? Why aren't there any mills with rollers that are motorized and 'done', that are not semi-industrial?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)