Ok - I am going to add my .02 here -

I have been using Sankes to serve in and ferment now for about 8 months. What I have been doing is taking the tube out if it is a serving keg, then putting them on my "bucket pump cleaner" which has 1/3hp pump in it and a 1/2" outlet on top - then putting using a healthy dose of PBW at 120-140*F and letting it do it's magic for up to a few hours (yes I am that anal about it) - while turning it a qtr turn every half hour. This seems to have been working. It works wonders because I get about 2gal which sits in the bottom of it making it more sturdy on the bucket (but I usually prop it up with a chair just in case) but it really gets the top part of my keg clean as it soaks and moves the water around too.

Was thinking about getting a spray head that everyone has been talking about but this process (the hours spent) has been starting to wear on me - as I am doing more beer. I have two fermentation chambers and have three 15.5 sanke kegs, four 7.75 serving kegs, and two 1/6 kegs, which leaves me room to clean them as I ferment in one or two.

Let me break it down in detail (see first pic of me cleaning a 7.75 serving keg using the above method)

1 - PBW TAP water clean around 120-140*F - about 1.5 - 2 hours of cleaning

2 - Hot Rinses in TAP water at the same temp - I do 3 or 4 rinses and roll it around hard on the rug in my garage on its side - upside down swirls, right side swirls too - for around 15-20 min each time - ~1 hr

3 - Cold FILTERED water rinse 15 min - same as above

4 - StarSan in FILTERED water rinse - 15 min same as above

5 - Drain and let it sit on the blue carboy drainer for a few hours

Total Time - as I have actually timed this is ~4-5 hours - just for one keg (thankfully I can do things while I wait)

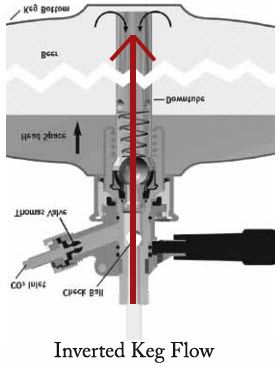

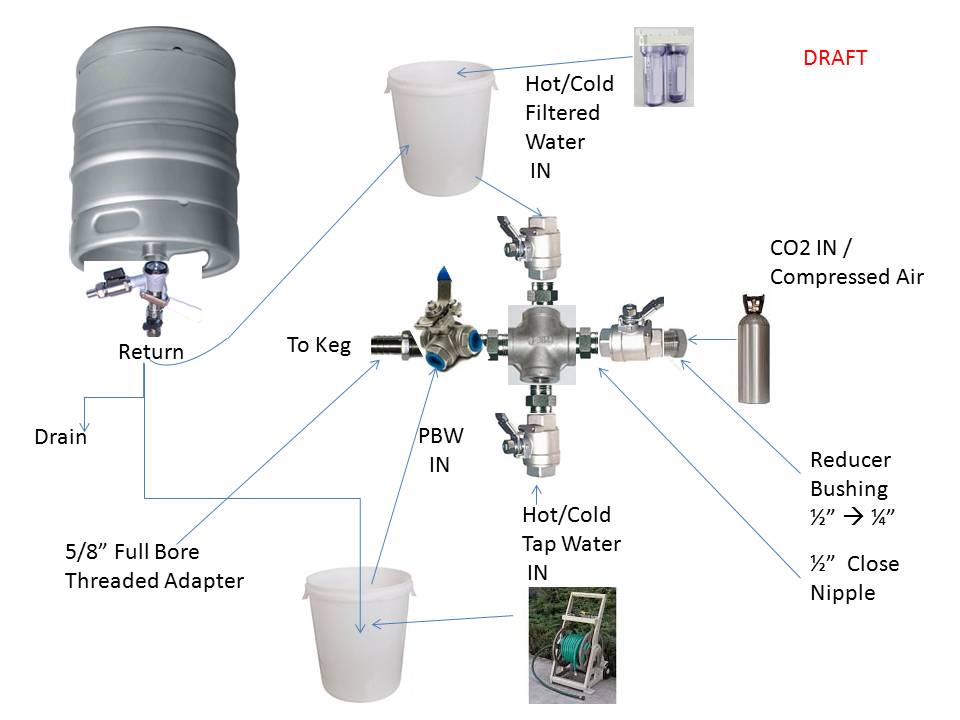

While I have had good luck with this so far - it is just too much time and energy for me - imho. And so now I am embarking on a new project - similar to MarcB where he made a commercial style keg inverted cleaner - a two tank job and a AC-5B-MD pump with hot PBW from heat stick.

While he and others talk about using a March ac5 or better pump - I just don't think spending $395-600 for a pump is going to make sense to me - again just my humble opinion based on my budget right now.

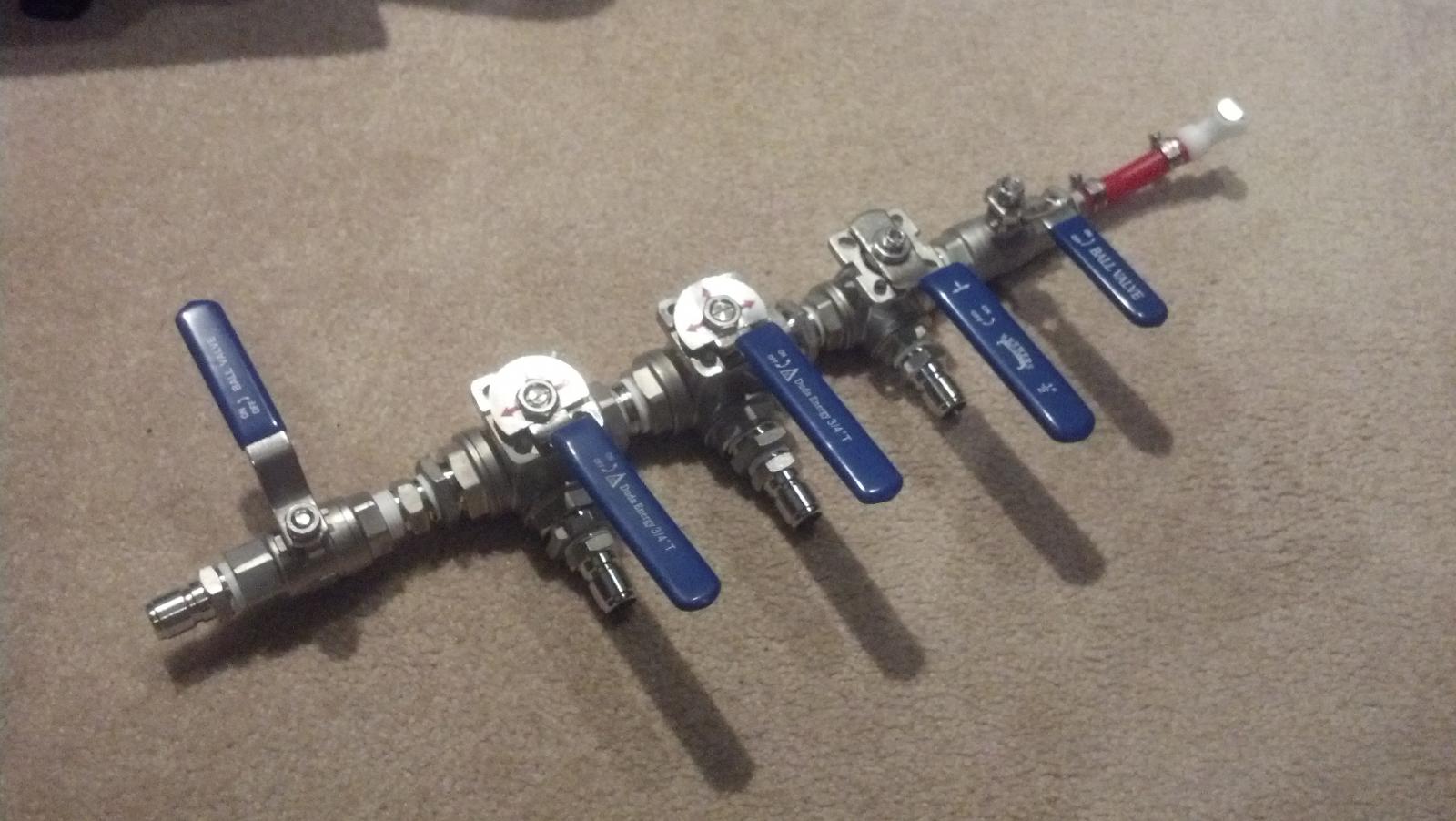

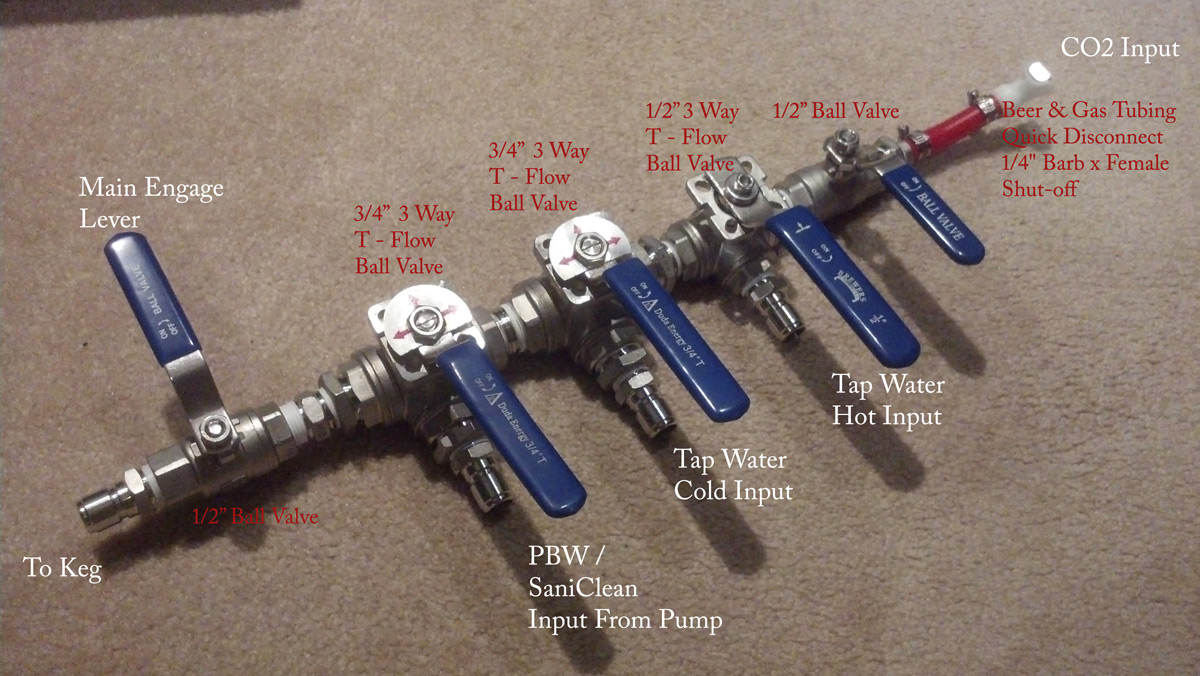

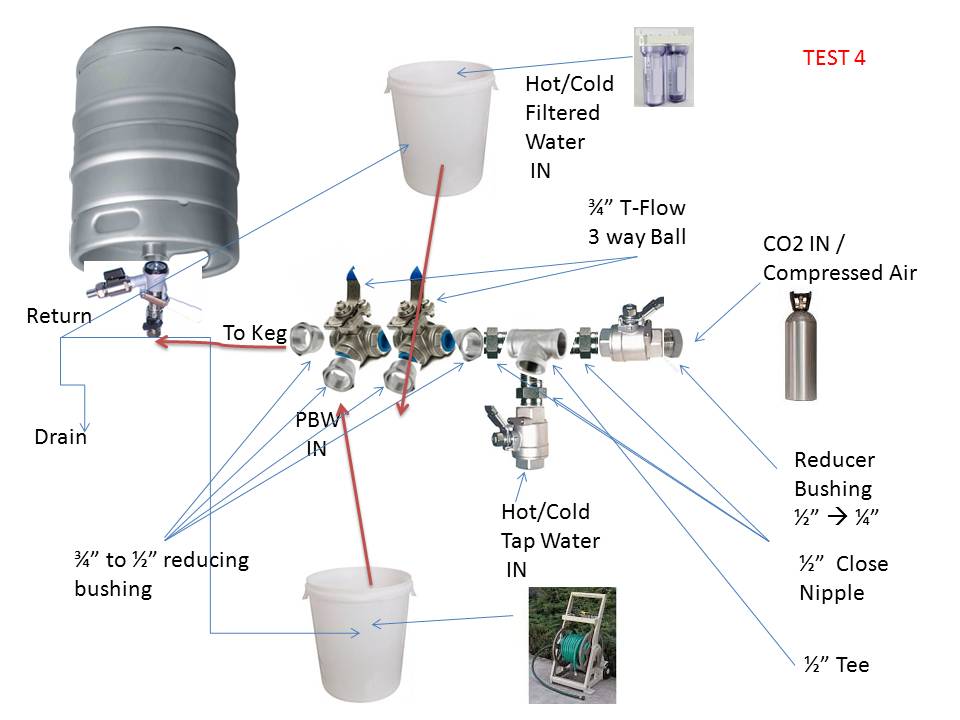

I bought the 1/2" keg tailpieces from Micromatic last week and did a test this weekend and will follow up with more pics and vids as I do them. My test was to take my basic 1/3hp pump in a bucket and shoot the water through the 1/2" tube up into a 1/2" tube which then was received by the 1/2" tailpiece in the coupler and sent through the coupler into the tube and out. See pic below. The idea was to understand how far the water was thrown into the air. The idea was if that worked I could then use the pump to channel it into the inverted keg with it's coupler/tap attached and set this system up using two 1/3hp pumps (superior sumps) in two different buckets for the clean and rinse methods using my two burners and my boil and HLT as reservoirs.

My problem was I couldn't get the water to travel up as far as I liked. This week I intend on getting the Sabco (https://www.brewmagic.com/product/wash-head-tap/) wash head tap to see if this helps with the throughput into the tube. Then making a 3/4" pipe from the pump to a 3/4" tube and then into the inverted keg.

Does anyone know the actual clearance from the tube and the bottom of the keg? This would help me greatly.

EDIT: it looks as if it is around 7/8" based on measuring.

more as I do this...

I have been using Sankes to serve in and ferment now for about 8 months. What I have been doing is taking the tube out if it is a serving keg, then putting them on my "bucket pump cleaner" which has 1/3hp pump in it and a 1/2" outlet on top - then putting using a healthy dose of PBW at 120-140*F and letting it do it's magic for up to a few hours (yes I am that anal about it) - while turning it a qtr turn every half hour. This seems to have been working. It works wonders because I get about 2gal which sits in the bottom of it making it more sturdy on the bucket (but I usually prop it up with a chair just in case) but it really gets the top part of my keg clean as it soaks and moves the water around too.

Was thinking about getting a spray head that everyone has been talking about but this process (the hours spent) has been starting to wear on me - as I am doing more beer. I have two fermentation chambers and have three 15.5 sanke kegs, four 7.75 serving kegs, and two 1/6 kegs, which leaves me room to clean them as I ferment in one or two.

Let me break it down in detail (see first pic of me cleaning a 7.75 serving keg using the above method)

1 - PBW TAP water clean around 120-140*F - about 1.5 - 2 hours of cleaning

2 - Hot Rinses in TAP water at the same temp - I do 3 or 4 rinses and roll it around hard on the rug in my garage on its side - upside down swirls, right side swirls too - for around 15-20 min each time - ~1 hr

3 - Cold FILTERED water rinse 15 min - same as above

4 - StarSan in FILTERED water rinse - 15 min same as above

5 - Drain and let it sit on the blue carboy drainer for a few hours

Total Time - as I have actually timed this is ~4-5 hours - just for one keg (thankfully I can do things while I wait)

While I have had good luck with this so far - it is just too much time and energy for me - imho. And so now I am embarking on a new project - similar to MarcB where he made a commercial style keg inverted cleaner - a two tank job and a AC-5B-MD pump with hot PBW from heat stick.

While he and others talk about using a March ac5 or better pump - I just don't think spending $395-600 for a pump is going to make sense to me - again just my humble opinion based on my budget right now.

I bought the 1/2" keg tailpieces from Micromatic last week and did a test this weekend and will follow up with more pics and vids as I do them. My test was to take my basic 1/3hp pump in a bucket and shoot the water through the 1/2" tube up into a 1/2" tube which then was received by the 1/2" tailpiece in the coupler and sent through the coupler into the tube and out. See pic below. The idea was to understand how far the water was thrown into the air. The idea was if that worked I could then use the pump to channel it into the inverted keg with it's coupler/tap attached and set this system up using two 1/3hp pumps (superior sumps) in two different buckets for the clean and rinse methods using my two burners and my boil and HLT as reservoirs.

My problem was I couldn't get the water to travel up as far as I liked. This week I intend on getting the Sabco (https://www.brewmagic.com/product/wash-head-tap/) wash head tap to see if this helps with the throughput into the tube. Then making a 3/4" pipe from the pump to a 3/4" tube and then into the inverted keg.

Does anyone know the actual clearance from the tube and the bottom of the keg? This would help me greatly.

EDIT: it looks as if it is around 7/8" based on measuring.

more as I do this...

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)