It has taken WAY longer than it should have for me to get to this point, but last weekend I was finally able to take my new brew rig for a test run. I've been spending a lot of time on HBT since getting back into brewing a couple of years ago. Last year I built a stir plate (had to figure out how to do that with a 4-wire PWM fan) and an fermentation chamber based on an STC-1000 and a Whirlpool 7.2cf chest freezer.

I also started mulling over what I wanted in the way of an all-grain setup. My objectives were as follows:

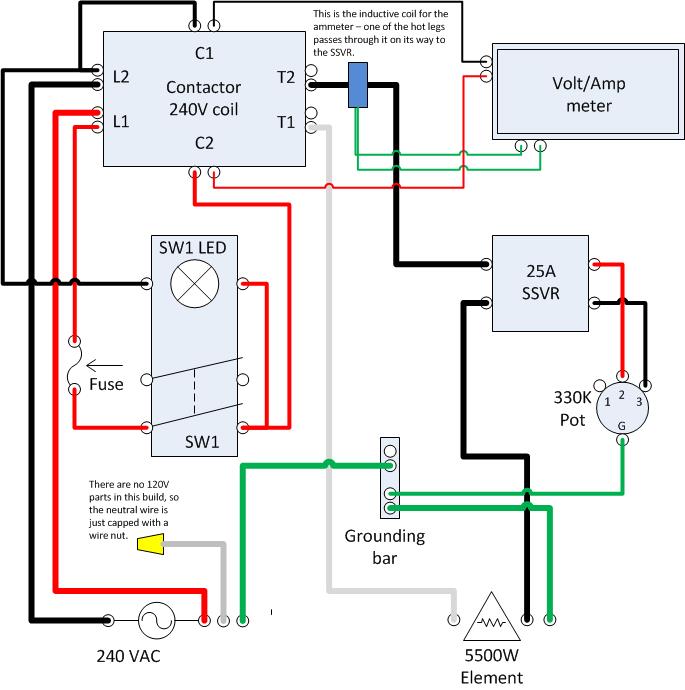

I decided early on that BIAB seemed like a good place to start - fewer vessels to store and clean. PID-based controllers are fascinating and definitely the way to go in a 3-vessel system, but in a BIAB setup it just seems to me that a knob is all that's needed. About the time I was ready to start building a PWM-based controller, Auber came out with their solid state voltage regulator.

So, here's what I came up with. The vessel is a bottom-drained e-keggle with a single 5500W element driven by a SSVR-based controller. The voltmeter/ammeter looks a bit blingy but it's actually there to give me an indication of the power that is being supplied to the element (the relationship between knob position and power output is non-linear).

There are a few more pictures in my gallery (use the link in my sig).

I also started mulling over what I wanted in the way of an all-grain setup. My objectives were as follows:

- Electric powered

- Capable of brewing 5-6 gallon batches

- Compact and storable

- Easy cleanup

- As simple as possible (no pumps, purpose-built sculpture, etc.)

- Fun to build

I decided early on that BIAB seemed like a good place to start - fewer vessels to store and clean. PID-based controllers are fascinating and definitely the way to go in a 3-vessel system, but in a BIAB setup it just seems to me that a knob is all that's needed. About the time I was ready to start building a PWM-based controller, Auber came out with their solid state voltage regulator.

So, here's what I came up with. The vessel is a bottom-drained e-keggle with a single 5500W element driven by a SSVR-based controller. The voltmeter/ammeter looks a bit blingy but it's actually there to give me an indication of the power that is being supplied to the element (the relationship between knob position and power output is non-linear).

There are a few more pictures in my gallery (use the link in my sig).

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)