A cut and paste from another thread because people seem to miss this stuff.

There are 2 ways to get 240VAC in a kitchen without rewiring anything.

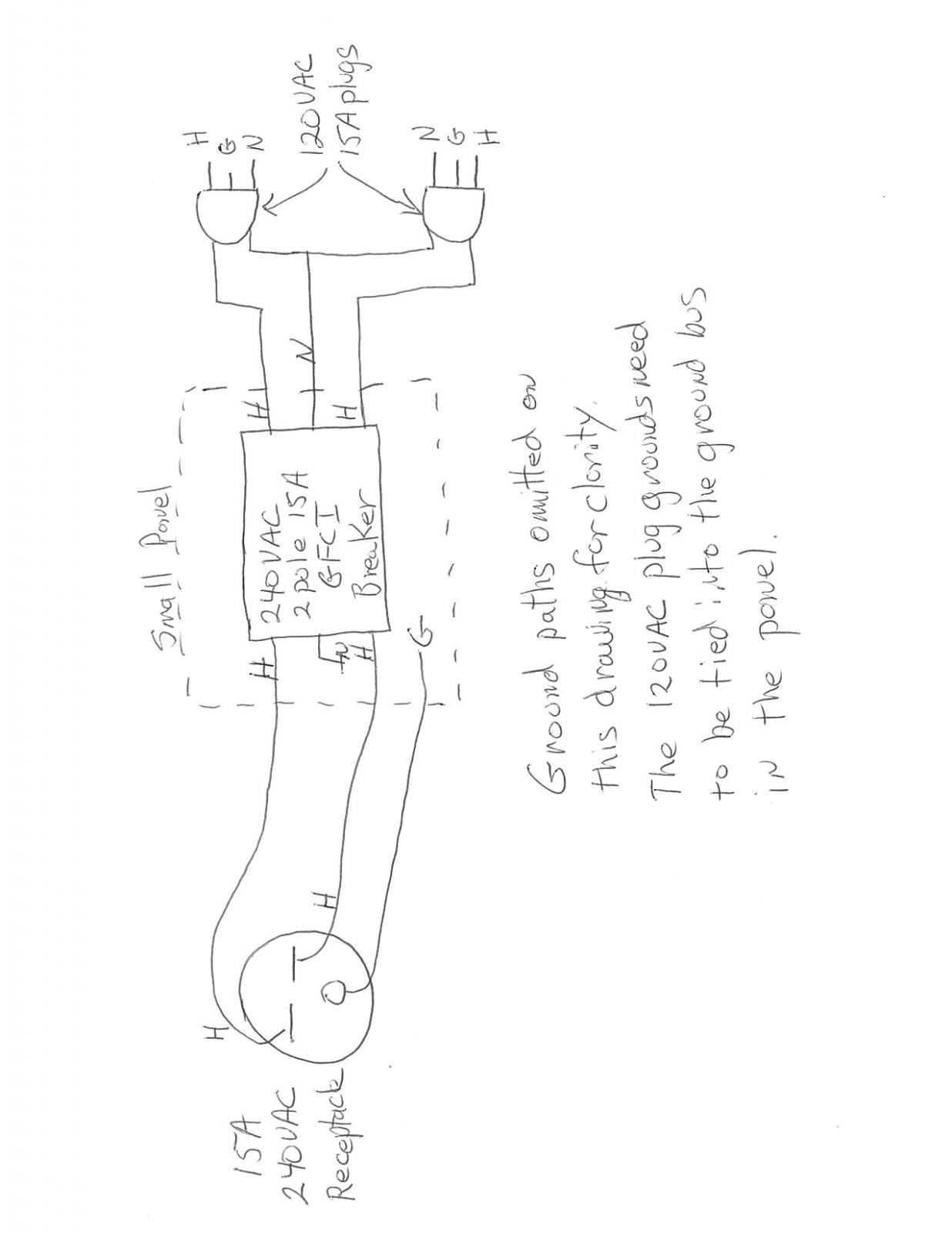

1) Plug the unit into the stove receptacle. This will require replacing the stove breaker with a GCFI breaker at the very least. Or you can wire up a small 2 breaker panel with a GFCI in it and a plug that plugs into the stove receptacle.

2) Find 2 120VAC plugs that are wired to opposite sides of the 240VAC supply. Build an adapter cord to go from 2 120VAC plugs to the 240VAC receptacle that the unit requires. The breakers on both 120VAC circuits will need to be replaced with GFCI breakers or wire in a small 2 breaker panel and put a 2 pole GCFI in it. This circuit will function exactly like a normal 15A 240VAC circuit would, only the 2 hot wires come from 2 different plugs rather than 1.

One can pull 240VAC x 15A = 3600 watts from 2 standard 120VAC plugs wired to opposite sides of the 240VAC supply.

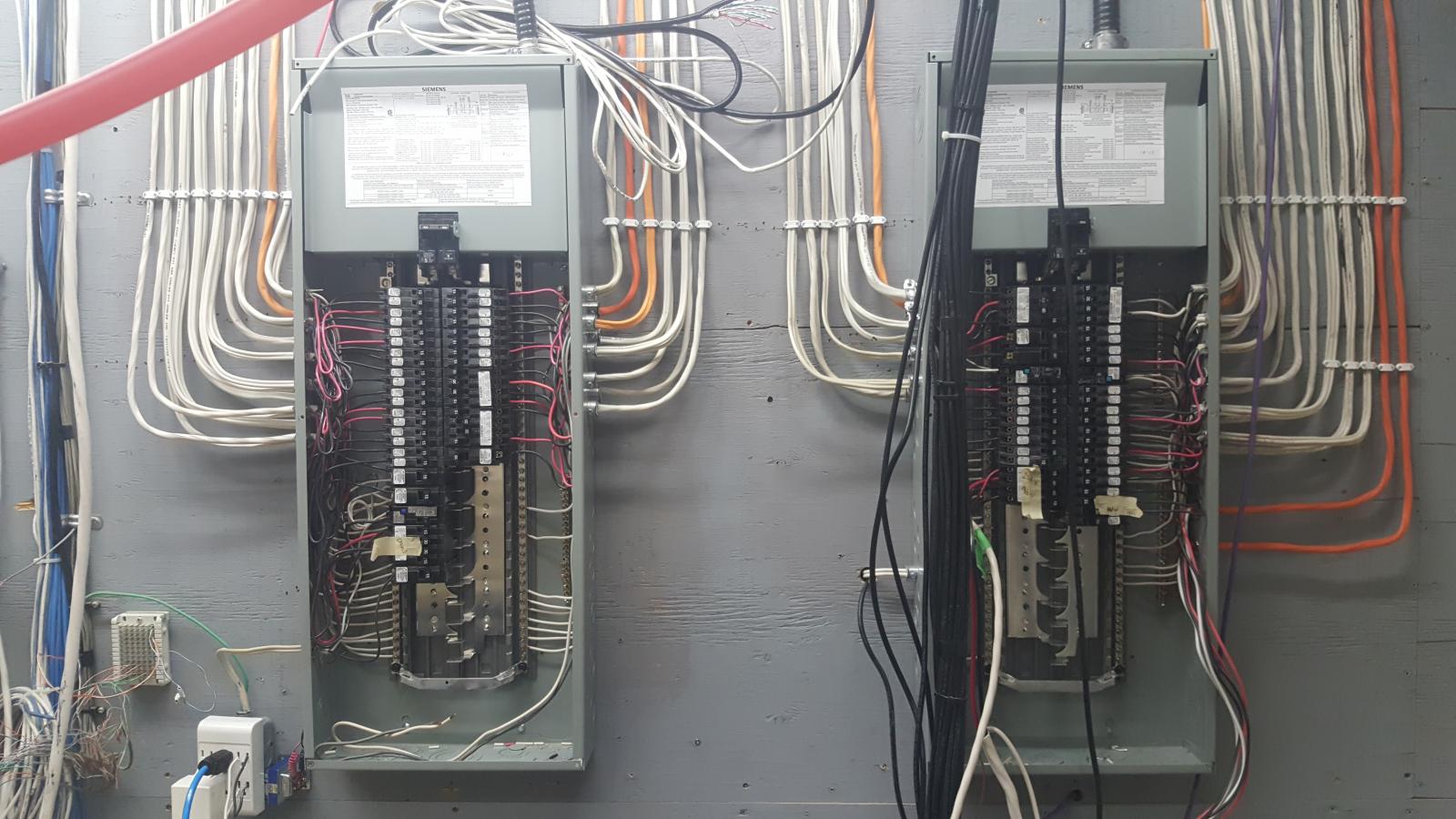

If the garage has a panel in it, it is very easy to put a device box on the panel with a simple connector, pop in a GFCI breaker and install a receptacle in the device box.

If the garage has plugs on multiple breakers, it is possible that they may be on opposite sides of the 240V supply, just like in a kitchen.

You can also get 240VAC power from a dryer plug.

I hope this helps.

There are 2 ways to get 240VAC in a kitchen without rewiring anything.

1) Plug the unit into the stove receptacle. This will require replacing the stove breaker with a GCFI breaker at the very least. Or you can wire up a small 2 breaker panel with a GFCI in it and a plug that plugs into the stove receptacle.

2) Find 2 120VAC plugs that are wired to opposite sides of the 240VAC supply. Build an adapter cord to go from 2 120VAC plugs to the 240VAC receptacle that the unit requires. The breakers on both 120VAC circuits will need to be replaced with GFCI breakers or wire in a small 2 breaker panel and put a 2 pole GCFI in it. This circuit will function exactly like a normal 15A 240VAC circuit would, only the 2 hot wires come from 2 different plugs rather than 1.

One can pull 240VAC x 15A = 3600 watts from 2 standard 120VAC plugs wired to opposite sides of the 240VAC supply.

If the garage has a panel in it, it is very easy to put a device box on the panel with a simple connector, pop in a GFCI breaker and install a receptacle in the device box.

If the garage has plugs on multiple breakers, it is possible that they may be on opposite sides of the 240V supply, just like in a kitchen.

You can also get 240VAC power from a dryer plug.

I hope this helps.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)