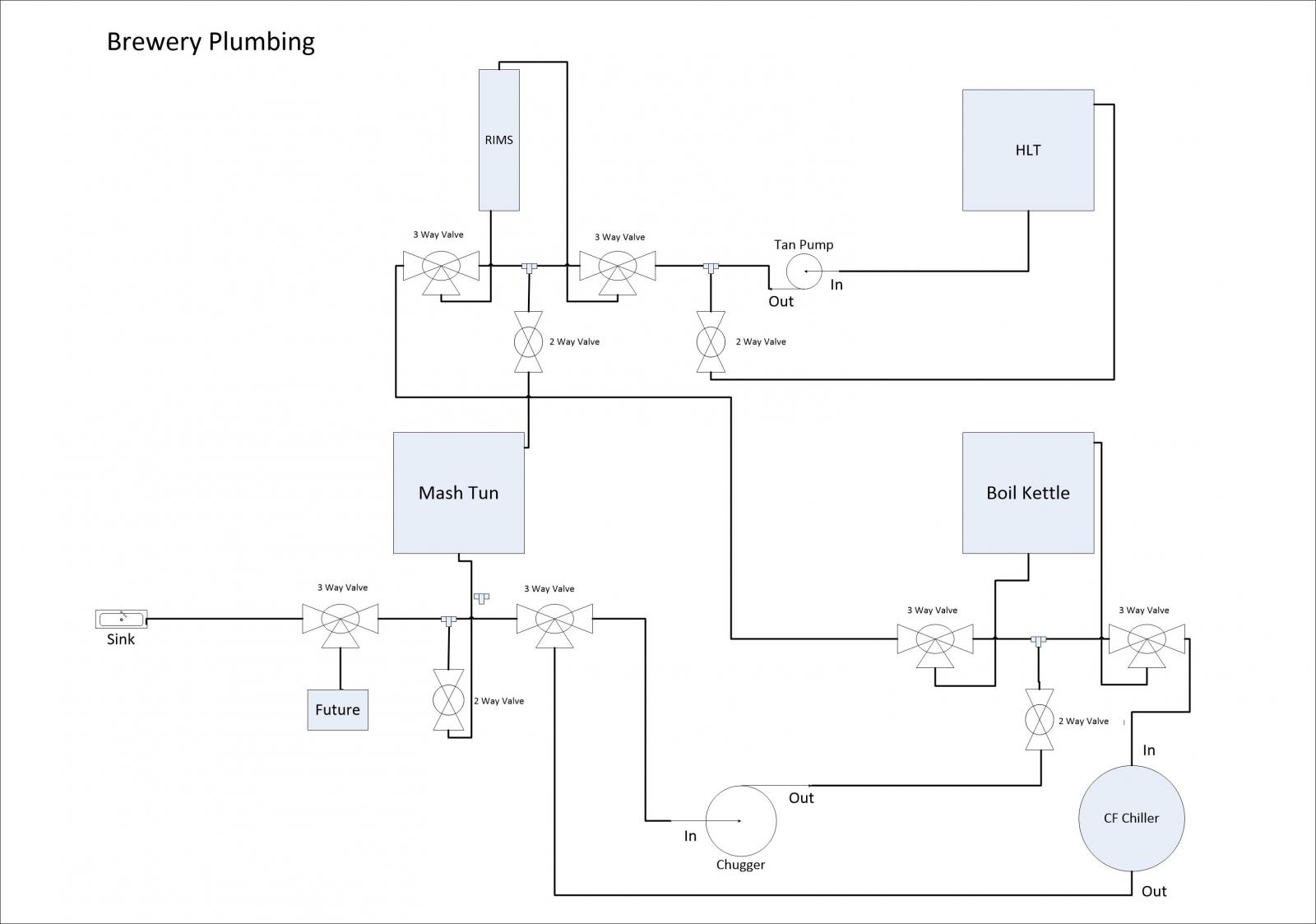

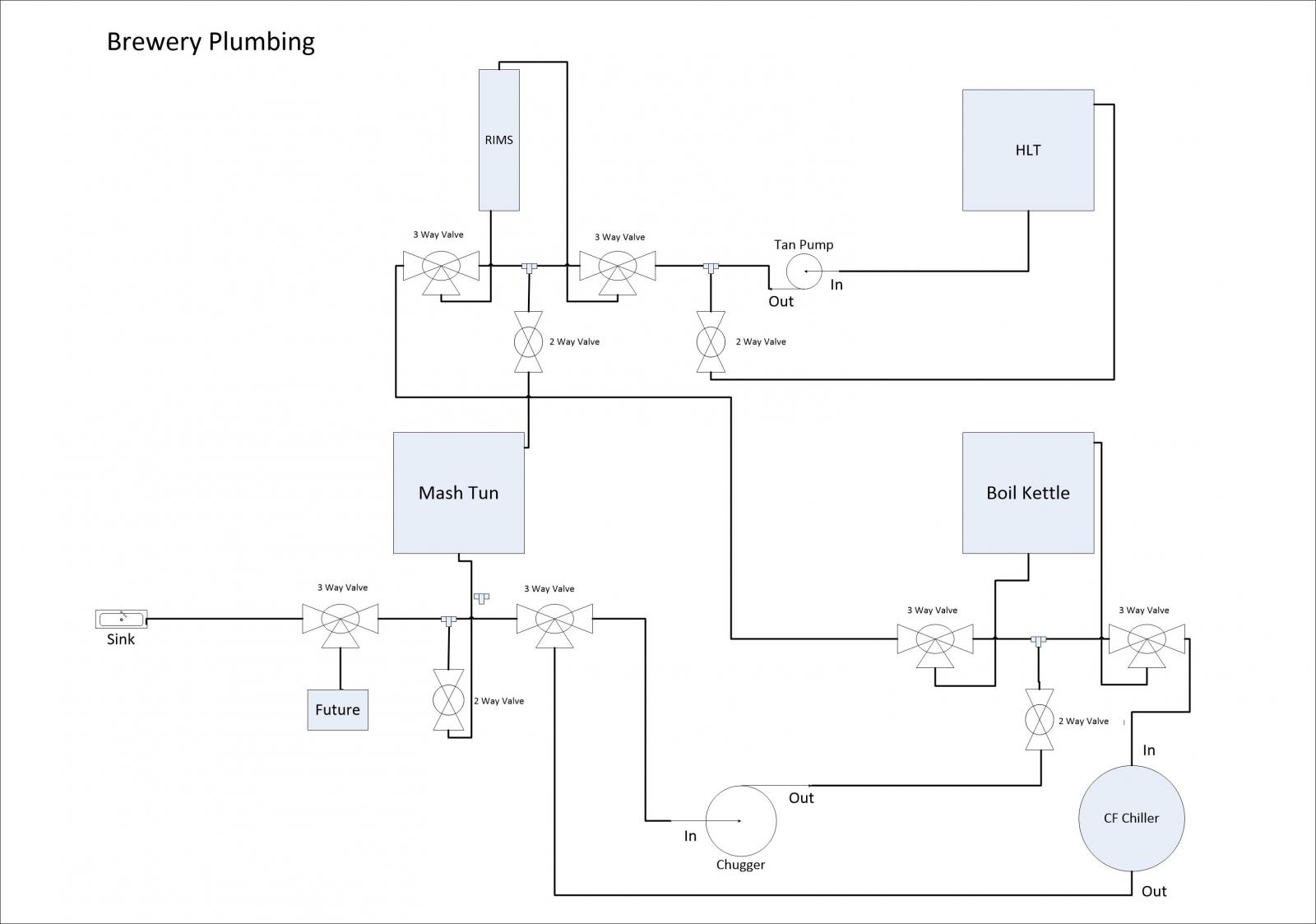

There are a lot of valves!

While planning it out, after putting it together and and continuing to look at it, I could for sure reduce the number of valves, as long as I don't want to change anything.

For example, if I have a 2way valve on the output of my MT, HLT or Boil Kettle and the hose goes to another 2 way valve on the other end, the second valve is probably not always necessary. Where there are 3 way valves with a "T" and a 2 way valve hung off the "T" ,I could eliminate the 2 way valve, as long as there is a valve on the other end of the hose. Nothing is going to get through that point unless the opposite end is opened. That is great during brewing but it would limit what I could do at that point if I ever wanted to move hoses or disconnect the other end for cleaning (i.e. the mash tun after mashing). So having a valve on both ends of a hose does give me the opportunity to pull hoses and move things around should I find the need, without a lot of forethought and mess.

Also, as Augiedoggie says If I added another dedicated tan pump or two I could isolate one or two spots and not have to keep swapping in the chugger pump. I may do this once I am convinced that I can eliminate grain particles from the RIMS recirculation portion. I also run water backwards through the pumps when I am filling the HLT.

Cleaning it shouldn't be a big deal. When I am done, since I have a sink right next to the stand I can circulate a few gallons of Oxiclean throughout and then run hot water through everything to rinse it.

In answer to the "How is it on a Brew day?" question. I will let you know.

I plan on brewing in a couple days. I do know that I will probably be drinking nothing stronger than coffee and soda.

It is hard enough for me to figure out brewing manually moving things around. I think using the new system is really going to tax my mental abilities at first.

![20170117_233515[1].jpg 20170117_233515[1].jpg](https://cdn.homebrewtalk.com/data/attach/329/329696-20170117-233515-1-.jpg)

![20170117_233515[1].jpg 20170117_233515[1].jpg](https://cdn.homebrewtalk.com/data/attach/329/329696-20170117-233515-1-.jpg)

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

![IMG_20170121_140632324[1].jpg IMG_20170121_140632324[1].jpg](https://cdn.homebrewtalk.com/data/attach/330/330151-IMG-20170121-140632324-1-.jpg)