I have a 1 gallon pitcher that I use for measuring my water volumes right now, but I don't necessarily trust the 1 gallon marking to be exactly 1 gallon, nor do I really trust my ability to guesstimate fractions of a gallon within it. I weigh my water additions and hops on a tiny little scale that only has a pound or two capacity.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wildly varying BIAB efficiency frustrations. What do I do?

- Thread starter vance

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

You are quoting efficiency numbers that you have achieved, but without accurate measurements of water volumes, you really cannot say where your inconsistency issue is coming from. While it is easy (and probably not without merit) to blame crush, you will never get any idea of how much of the variability comes from the grain crush versus inconsistency within your process if you don't measure and enter into BeerSmith the best measurements for volumes and gravity at each step you can.

Yeah, I'm aware. The two measurements I have any certainty on are my initial strike water volume and my volume into the fermenter, but the rest I have no way to measure until I get a dipstick or something together.

I hit 85%-90% efficiency pretty regularly on my BIAB but I do crush my own grain (Cereal Killer). I also squeeze, sparge, then squeeze again.

That really sucks about the ruler. I had to look at a ton of rulers to find one without that stupid cork backing. Maybe you could take a grinder to it?

That really sucks about the ruler. I had to look at a ton of rulers to find one without that stupid cork backing. Maybe you could take a grinder to it?

I have a 1 gallon pitcher that I use for measuring my water volumes right now, but I don't necessarily trust the 1 gallon marking to be exactly 1 gallon, nor do I really trust my ability to guesstimate fractions of a gallon within it.

Oh yeah, and there's that! Just as quickly as one can convert 0.63 gallons to quarts/cups/whatever and dose that out one could more accurately pull out there phone and convert to 0.63x8.32=5.24 lb and weigh that out directly in the pitcher... or maybe even quicker?

As has been well covered, efficiency calculations are only as good as the volume (and grain weight, and SG) measurements. I use the marked wooden dowel method, and calibrated by weighing out 1 gal (8.3304 lb/gal @ 68˚F) increments and marking the dowel. I had tried first with a marked 1 gal pitcher, but found its markings weren't accurate enough.

Once you get your measurements down, then you know if you really have efficiency inconsistencies. There are several different efficiencies you can calculate:

To get consistent overall efficiency, you need to get consistency in all of the individual elements: conversion efficiency, lauter efficiency, and transfer efficiency.

Crush, mash time and mash temp have the largest effect on conversion efficiency. You can determine your conversion efficiency from the grain bill weight, strike water volume and mash wort SG using the method described here. Your conversion efficiency should be 95% or better. Since you can't really improve your crush (yet), your best bet is to extend your mash times. If you have a refractometer, it is easy to monitor your wort SG as the mash progresses, in order to determine when your mash is "done."

There is a lot of software (BrewSmith, BrewersFriend, etc.) that will calculate your mash efficiency from your pre-boil volume, pre-boil SG, and grain bill. And the same calculation can be done with post-boil volume, post-boil SG, and grain bill, as long as no sugar was added during the boil. Once you have your mash efficiency and conversion efficiency, then calculate lauter efficiency as: lauter eff = mash eff / conv eff.

Lauter efficiency will be determined by the consistency of your sparge process (if you use one) and the consistency of your bag draining and/or squeezing. Batch sparging can be very consistent. Pouring sparge water over the bag will be less consistent. Consistency of draining/squeezing is determined by calculating the grain absorption ratio, which equals (strike volume - 1st runnings volume) / grain weight.

Transfer efficiency is just fermenter volume / post-boil volume, so you want to be consistent in the fraction of the post-boil volume that gets left in the BK.

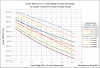

And as mentioned by others, efficiency will vary with the size of the grain bill (for same size batches), with larger grain bills having lower efficiency. This is all due to the effect on lautering efficiency caused by more grain absorbing a greater fraction of the total wort volume. The chart below shows how lauter efficiency is affected by grain bill. To normalize for different batch sizes, the X axis is grain bill weight / pre-boil volume. Different curves represent the effects of sparge vs. no-sparge, and various grain absorption rates (levels of squeezing.)

Brew on

Once you get your measurements down, then you know if you really have efficiency inconsistencies. There are several different efficiencies you can calculate:

Conversion Efficiency: The actual amount of sugar created in the mash divided by the potential amount of sugar in the grain bill.

Lauter Efficiency: The amount of sugar that makes it into your boil kettle divided by the amount of sugar that was created in the mash.

Mash Efficiency: a.k.a. Pre-Boil Efficiency. The amount of sugar that makes it into your boil kettle divided by the potential amount of sugar in the grain bill. Mash Efficiency equals Conversion Efficiency times Lauter Efficiency.

Transfer Efficiency: The amount of sugar in your fermenter divided by the amount of sugar in your boil kettle. Also equal to the fermenter volume divided by the post-boil volume.

Brewhouse Efficiency: The amount of sugar that makes it into your fermenter divided by the potential amount of sugar in the grain bill. Brewhouse Efficiency equals Mash Efficiency times Transfer Efficiency. Also equals Conversion Efficiency times Lauter Efficiency times Transfer Efficiency.

All of the above definitions are for fractional efficiency. You can convert any fractional efficiency to percentage by multiplying by 100%. However, if you are multiplying efficiencies together, you need to do that with fractional efficiencies.Lauter Efficiency: The amount of sugar that makes it into your boil kettle divided by the amount of sugar that was created in the mash.

Mash Efficiency: a.k.a. Pre-Boil Efficiency. The amount of sugar that makes it into your boil kettle divided by the potential amount of sugar in the grain bill. Mash Efficiency equals Conversion Efficiency times Lauter Efficiency.

Transfer Efficiency: The amount of sugar in your fermenter divided by the amount of sugar in your boil kettle. Also equal to the fermenter volume divided by the post-boil volume.

Brewhouse Efficiency: The amount of sugar that makes it into your fermenter divided by the potential amount of sugar in the grain bill. Brewhouse Efficiency equals Mash Efficiency times Transfer Efficiency. Also equals Conversion Efficiency times Lauter Efficiency times Transfer Efficiency.

To get consistent overall efficiency, you need to get consistency in all of the individual elements: conversion efficiency, lauter efficiency, and transfer efficiency.

Crush, mash time and mash temp have the largest effect on conversion efficiency. You can determine your conversion efficiency from the grain bill weight, strike water volume and mash wort SG using the method described here. Your conversion efficiency should be 95% or better. Since you can't really improve your crush (yet), your best bet is to extend your mash times. If you have a refractometer, it is easy to monitor your wort SG as the mash progresses, in order to determine when your mash is "done."

There is a lot of software (BrewSmith, BrewersFriend, etc.) that will calculate your mash efficiency from your pre-boil volume, pre-boil SG, and grain bill. And the same calculation can be done with post-boil volume, post-boil SG, and grain bill, as long as no sugar was added during the boil. Once you have your mash efficiency and conversion efficiency, then calculate lauter efficiency as: lauter eff = mash eff / conv eff.

Lauter efficiency will be determined by the consistency of your sparge process (if you use one) and the consistency of your bag draining and/or squeezing. Batch sparging can be very consistent. Pouring sparge water over the bag will be less consistent. Consistency of draining/squeezing is determined by calculating the grain absorption ratio, which equals (strike volume - 1st runnings volume) / grain weight.

Transfer efficiency is just fermenter volume / post-boil volume, so you want to be consistent in the fraction of the post-boil volume that gets left in the BK.

And as mentioned by others, efficiency will vary with the size of the grain bill (for same size batches), with larger grain bills having lower efficiency. This is all due to the effect on lautering efficiency caused by more grain absorbing a greater fraction of the total wort volume. The chart below shows how lauter efficiency is affected by grain bill. To normalize for different batch sizes, the X axis is grain bill weight / pre-boil volume. Different curves represent the effects of sparge vs. no-sparge, and various grain absorption rates (levels of squeezing.)

Brew on

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

calibrated by weighing out 1 gal (8.3304 lb/gal @ 68˚F)

Ahem, my tap water is 72F

I have a 1 gallon pitcher that I use for measuring my water volumes right now, but I don't necessarily trust the 1 gallon marking to be exactly 1 gallon, nor do I really trust my ability to guesstimate fractions of a gallon within it. I weigh my water additions and hops on a tiny little scale that only has a pound or two capacity.

You have a measuring cup, right? Measure out amounts until you get to exactly one gallon, then use a sharpie or piece of tape or some such to mark that spot on the pitcher. You can mark intermediate amounts as well.

But I have to tell you--in my view this focus on amount of water is unlikely to be the amount of water you're using, it's almost certainly in the process somewhere. You don't want a mill, can't address whether it's crush or something else, so you're focusing on something else (water).

Here's something related to process: when I first started doing all-grain, my numbers were a bit low. I read on HBT about stirring the mash at 15 and at 30 minutes to ensure even temp and even distribution of enzymes, and guess what? Efficiency shot up. Are you stirring? If not, that's an example of a process variable that can be changed.

If it were too much water, you'd end up w/ something like 6.5 gallons going into the fermenter. Or if you have too little, that doesn't make sense if you're starting with something like 8.5 gallons. Is something happening w/ the boil that you're not concentrating the wort enough? Or too much? I boil off about a gallon, so my start is generally 6.5 to 6.75 gallons. I leave a bit in the bottom of the fermenter so when I rack it I'm not drawing trub into the keg.

You have a measuring cup, right? Measure out amounts until you get to exactly one gallon, then use a sharpie or piece of tape or some such to mark that spot on the pitcher. You can mark intermediate amounts as well.

I hope I'm not being to picky by specifying that the measuring cup should probably be a liquid measuring cup.

https://www.cooksillustrated.com/how_tos/5450-dry-versus-liquid-measuring-cups

berndawg84

Well-Known Member

- Joined

- Sep 29, 2016

- Messages

- 94

- Reaction score

- 23

I hit 85%-90% efficiency pretty regularly on my BIAB but I do crush my own grain (Cereal Killer). I also squeeze, sparge, then squeeze again.

That really sucks about the ruler. I had to look at a ton of rulers to find one without that stupid cork backing. Maybe you could take a grinder to it?

With doing a sparge, how do you calculate your strike water volume that you need? I do BIAB and typically your strike water is all of the water you'll need for mash and boil. I have efficiency problems as well, and am looking at solutions.

From what I've gathered, grain crush and mash pH seem to be 2 of the biggest factors in BIAB efficiency. BYO had an issue all about BIAB, and it was discussed in there (Brad Smith article I think). So if you're wanting to increase your efficiency, as others have said, it does seem like a grain mill is a great way to go.

I double crush my grains at the LBHS, but I can't seem to tell a visual difference b/w how the grains look from crush 1 to crush 2. And if you're crushing at a normal gap, instead of a tighter BIAB gap, that makes sense. for BIAB the ideal, it seems, is for the grains to almost be like flour.

Here's a link to the BYO issue, you can order it online. It was worth the purchase for me. It also discusses mash pH, and how getting it right can increase efficiency. So it seems like a grain mill and a pH meter are worthy purchases. I'm going to get a cheapo pH meter next, eventually a grain mill.

https://byo.com/stories/issue/itemlist/category/222-may-jun-2016

Ahem, my tap water is 72F

Which is the problem with using volumes. All of the efficiency calculations really use water weight if they are trying to be rigorous. We use volumes as a surrogate measurement for weight (and bury the conversion to weight under the covers.) The "industry standard" for doing SG <-> Plato conversions is 68˚F (20˚C.) Which is why I adjust all volume measurements at whatever temp to volume @ 68˚F. The error in using uncorrected volume to determine weight is negligible for a reasonable range around 68˚.

Brew on

With doing a sparge, how do you calculate your strike water volume that you need? I do BIAB and typically your strike water is all of the water you'll need for mash and boil. I have efficiency problems as well, and am looking at solutions.

I always use 2 gallons of sparge water, just because that's how big my other pot is.

Which is the problem with using volumes. All of the efficiency calculations really use water weight if they are trying to be rigorous. We use volumes as a surrogate measurement for weight (and bury the conversion to weight under the covers.) The "industry standard" for doing SG Plato conversions is 68˚F (20˚C.) Which is why I adjust all volume measurements at whatever temp to volume @ 68˚F. The error in using uncorrected volume to determine weight is negligible for a reasonable range around 68˚.

Brew on

Hear, hear! Also why I don't understand why 3/3 lhbs's don't carry hydrometers calibrated at 68F. The only place I've found one is moorbeer.com but I wasn't prepared to pay the shipping.

With doing a sparge, how do you calculate your strike water volume that you need? I do BIAB and typically your strike water is all of the water you'll need for mash and boil. I have efficiency problems as well, and am looking at solutions.

From what I've gathered, grain crush and mash pH seem to be 2 of the biggest factors in BIAB efficiency. BYO had an issue all about BIAB, and it was discussed in there (Brad Smith article I think). So if you're wanting to increase your efficiency, as others have said, it does seem like a grain mill is a great way to go.

I double crush my grains at the LBHS, but I can't seem to tell a visual difference b/w how the grains look from crush 1 to crush 2. And if you're crushing at a normal gap, instead of a tighter BIAB gap, that makes sense. for BIAB the ideal, it seems, is for the grains to almost be like flour.

Here's a link to the BYO issue, you can order it online. It was worth the purchase for me. It also discusses mash pH, and how getting it right can increase efficiency. So it seems like a grain mill and a pH meter are worthy purchases. I'm going to get a cheapo pH meter next, eventually a grain mill.

https://byo.com/stories/issue/itemlist/category/222-may-jun-2016

When doing a batch sparge, you get the maximum efficiency when your first runnings, and sparge runnings have the same volume. They don't have to be exactly the same as the difference between 60:40 or 40:60 and 50:50 is insignificant. So, just use 3/5 of your total brewing water for strike, and 2/5 of your total brewing water for sparge, and you will be close enough. If you are going to squeeze, then squeeze before sparge, and after sparge for best efficiency. The pre-sparge squeeze is the most critical.

Rather than getting a "cheapo" pH meter, you would be better served by getting a water report and using Bru'n Water to predict your pH. Bru'n Water predictions are usually better than cheap pH meter measurements. And, you need to predict your mash pH, because you cannot effectively adjust the pH during the mash (pH doesn't stabilize until well into the mash, at which time adjustment won't help much.) If you want to verify Bru'n Water's predictions, wait until you can afford a good pH meter, and learn how to calibrate it.

Also, read my post above on how to determine where your efficiency issues originate. If you don't know whether your conversion or lauter (or maybe both) is the problem, you don't know what kind of actions to take to improve your efficiency.

Brew on

You have a measuring cup, right? Measure out amounts until you get to exactly one gallon, then use a sharpie or piece of tape or some such to mark that spot on the pitcher. You can mark intermediate amounts as well.

But I have to tell you--in my view this focus on amount of water is unlikely to be the amount of water you're using, it's almost certainly in the process somewhere. You don't want a mill, can't address whether it's crush or something else, so you're focusing on something else (water).

Here's something related to process: when I first started doing all-grain, my numbers were a bit low. I read on HBT about stirring the mash at 15 and at 30 minutes to ensure even temp and even distribution of enzymes, and guess what? Efficiency shot up. Are you stirring? If not, that's an example of a process variable that can be changed.

If it were too much water, you'd end up w/ something like 6.5 gallons going into the fermenter. Or if you have too little, that doesn't make sense if you're starting with something like 8.5 gallons. Is something happening w/ the boil that you're not concentrating the wort enough? Or too much? I boil off about a gallon, so my start is generally 6.5 to 6.75 gallons. I leave a bit in the bottom of the fermenter so when I rack it I'm not drawing trub into the keg.

My focus is less on water volumes and more on volumes in general. I have no real idea how much I'm losing to my grain, what my boil off rate is, or how much is actually left in the kettle because I have no way to measure those. I'm about to sit down to make a dipstick though so I should be able to figure a starting point for some of these this weekend.

When doing a batch sparge, you get the maximum efficiency when your first runnings, and sparge runnings have the same volume. They don't have to be exactly the same as the difference between 60:40 or 40:60 and 50:50 is insignificant. So, just use 3/5 of your total brewing water for strike, and 2/5 of your total brewing water for sparge, and you will be close enough. If you are going to squeeze, then squeeze before sparge, and after sparge for best efficiency. The pre-sparge squeeze is the most critical.

Rather than getting a "cheapo" pH meter, you would be better served by getting a water report and using Bru'n Water to predict your pH. Bru'n Water predictions are usually better than cheap pH meter measurements. And, you need to predict your mash pH, because you cannot effectively adjust the pH during the mash (pH doesn't stabilize until well into the mash, at which time adjustment won't help much.) If you want to verify Bru'n Water's predictions, wait until you can afford a good pH meter, and learn how to calibrate it.

Also, read my post above on how to determine where your efficiency issues originate. If you don't know whether your conversion or lauter (or maybe both) is the problem, you don't know what kind of actions to take to improve your efficiency.

Brew on

Is lauter efficiency a thing if I don't sparge? That's one portion of efficiency that's always confused me.

I use 100% RO water with bru'n water to set a good mash pH, although without a meter there's no way to really know for sure. A possible deficiency in bru'n water is my grain bill entry - for a while I didn't realize SRM and L were different, so I just entered Beersmith's SRM numbers. Two batches ago I realized they weren't the same, so I used https://www.brewtoad.com/tools/color-converter to convert.

Edit: Do you have any cheap refractometer recommendations? I never really take conversion measurements or pre-boil gravity measurements because my feeling is that by the time it cools down to the temperature where a hydrometer is accurate, it's too late to be really useful.

Barley_Bob

Well-Known Member

This thread is crazy. Get a stick, find a way to crush fine, and calibrate your thermometer.

This thread is crazy. Get a stick, find a way to crush fine, and calibrate your thermometer.

Crazy in what way? Thermometer has been calibrated, stick is being made this afternoon.

my feeling is that by the time it cools down to the temperature where a hydrometer is accurate, it's too late to be really useful.

Take about 3/4 cup or whatever it takes to fill your hydrometer tube, throw it in a cake pan to get lots of surface area and throw it in the freezer, it'll cool off in no time.

Take about 3/4 cup or whatever it takes to fill your hydrometer tube, throw it in a cake pan to get lots of surface area and throw it in the freezer, it'll cool off in no time.

The large surface area will also allow more evaporation of water from the wort while it is still hot. This will make the SG of the sample higher than the SG of the bulk wort. I'd use a narrow mouth container, cover it right after sampling, and put that in the freezer.

Brew on

Barley_Bob

Well-Known Member

Crazy in what way? Thermometer has been calibrated, stick is being made this afternoon.

BIAB just doesn't have to be this hard. I get that you want confirmation on your efficiency, and that's fine. But actually producing a successful mash is really simple, and you'll get it as long as you're paying attention to the few major components.

For example, when I calculate my mash water, I just do the 'ol (weight/4)*1.25 and then I round to a convenient interval. At the same time, there's folks who BIAB and combine mash and sparge water from the get go. So, I'm mashing with, like, 4 gallons, and they're mashing with, like 8. We both turn out fine beer.

You're gonna be okay.

berndawg84

Well-Known Member

- Joined

- Sep 29, 2016

- Messages

- 94

- Reaction score

- 23

My focus is less on water volumes and more on volumes in general. I have no real idea how much I'm losing to my grain, what my boil off rate is, or how much is actually left in the kettle because I have no way to measure those. I'm about to sit down to make a dipstick though so I should be able to figure a starting point for some of these this weekend.

Yea you really need to try to measure these things. Here's an easy way. Use a Nalgene water bottle or something else with measurement markings to get 3 or 4 gallons of water. Boil the water for 1 hour, then figure out how much you have left. As others have said, weighing the water is too tricky and inaccurate.

Also, for a hydrometer or refractometer, you can usually use a temp adjustment calculator like this one

https://www.brewersfriend.com/hydrometer-temp/

Without having to cool down your wort too much. The highest the calculator will is up to 159 F.

The large surface area will also allow more evaporation of water from the wort while it is still hot. This will make the SG of the sample higher than the SG of the bulk wort. I'd use a narrow mouth container, cover it right after sampling, and put that in the freezer.

Brew on

I do cover it with plastic wrap for that reason. I'd hoped it cooled quickly enough to not really make a difference. Have you or anyone actually measured a difference?

Is lauter efficiency a thing if I don't sparge? That's one portion of efficiency that's always confused me.

I use 100% RO water with bru'n water to set a good mash pH, although without a meter there's no way to really know for sure. A possible deficiency in bru'n water is my grain bill entry - for a while I didn't realize SRM and L were different, so I just entered Beersmith's SRM numbers. Two batches ago I realized they weren't the same, so I used https://www.brewtoad.com/tools/color-converter to convert.

Edit: Do you have any cheap refractometer recommendations? I never really take conversion measurements or pre-boil gravity measurements because my feeling is that by the time it cools down to the temperature where a hydrometer is accurate, it's too late to be really useful.

Of course lauter efficiency is important for no-sparge. Lautering is separating wort (sugar really) from the spent grains. The more sugar left with the spent grains, the lower the lauter efficiency. The amount of sugar retained with the grains is equal to the volume of wort retained times the concentration of the wort (in volume % sugar.) (Or more rigorously the weight of retained wort times time the wt% sugar in the wort.) So, less retained wort means higher lauter efficiency. Lower concentration of sugar in the retained wort means higher lauter efficiency. Squeezing lowers the amount of retained wort. Sparging lowers the concentration of the retained wort.

There are lots of low cost refractometers available, and they are pretty much all made in China and generic, so difficult to recommend "best." I would recommend getting a Brix only instrument. The ones that include an SG scale have to assume a "wort correction factor" and the factor they choose may not be appropriate for your system. Also, some are known to apply the wort correction factor incorrectly. So, just better to avoid refracts with SG scales. You can check your refract's calibration against distilled or RO water (should read zero, and most are adjustable to correct for offset), and a solution of 80 parts by weight water and 20 parts by weight table sugar (sucrose) - which should read 20 Brix.

Brew on

Last edited:

I haven't measured it because I use a refractometer for almost everything.I do cover it with plastic wrap for that reason. I'd hoped it cooled quickly enough to not really make a difference. Have you or anyone actually measured a difference?

Brew on

I hope I'm not being to picky by specifying that the measuring cup should probably be a liquid measuring cup.

https://www.cooksillustrated.com/how_tos/5450-dry-versus-liquid-measuring-cups

Yeah, too picky.

BIAB just doesn't have to be this hard. I get that you want confirmation on your efficiency, and that's fine. But actually producing a successful mash is really simple, and you'll get it as long as you're paying attention to the few major components.

For example, when I calculate my mash water, I just do the 'ol (weight/4)*1.25 and then I round to a convenient interval. At the same time, there's folks who BIAB and combine mash and sparge water from the get go. So, I'm mashing with, like, 4 gallons, and they're mashing with, like 8. We both turn out fine beer.

You're gonna be okay.

It doesn't have to be, no. I make fine beer anyways, but I'm kind of the person who likes to know exactly what is happening so I can predict and control it, which means making everything as accurate as I can

Barley_Bob

Well-Known Member

It doesn't have to be, no. I make fine beer anyways, but I'm kind of the person who likes to know exactly what is happening so I can predict and control it, which means making everything as accurate as I can

You do you, Buddy. But I promise, this will be in your rear view mirror and you'll be making great beer in no time.

Take about 3/4 cup or whatever it takes to fill your hydrometer tube, throw it in a cake pan to get lots of surface area and throw it in the freezer, it'll cool off in no time.

I didn't invent this method, read it on HBT (of course).

I have two whiskey tasting glasses that have a lot of glass in them. Prior to the beginning of brew day, I toss them in the freezer so they'll cool down.

I put my mash sample in them, pouring back and forth to cool the sample as quickly as I can. The wonder of the Thermapen MK4 is that I can quickly tell when I'm close to my room temperature goal, then I pour the cooled sample back in my beaker to test.

Takes not much more than a minute to do this.

In the pic below, there's the collapsible colander I use to push the grain out of the way so I can take a sample of grain-free wort, a turkey baster to take the sample, a small beaker into which I squirt the sample, and the two whiskey glasses I put in the freezer and use to cool the sample.

Similar threads

- Replies

- 3

- Views

- 286

- Replies

- 11

- Views

- 828

- Replies

- 5

- Views

- 411

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)