andrewmalizia

Well-Known Member

Bingo. Stupid engineer documentation trick

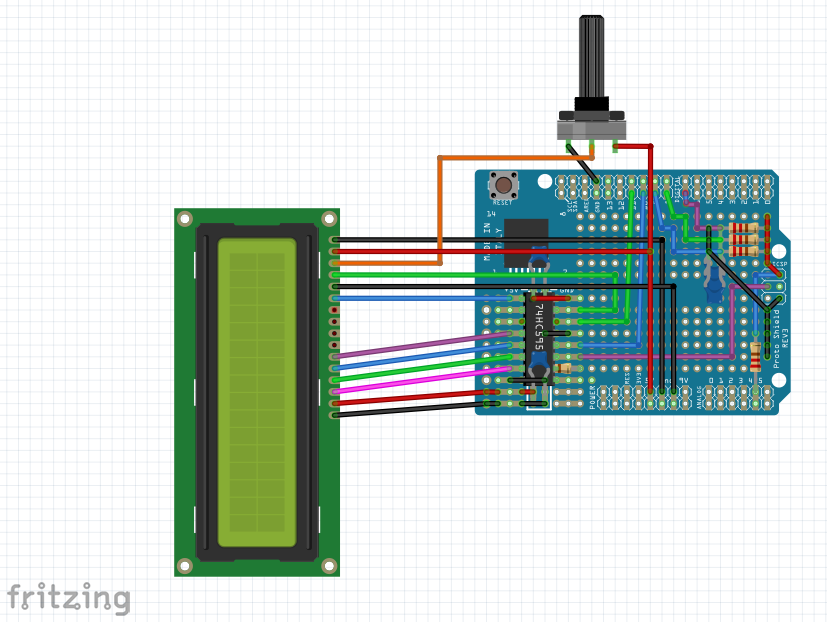

The grounds versus control signals were swapped at their respective switch inputs. Here's the corrected drawing...

Cheers!

Is there a reason you chose to bypass the relay board for the switching and go AC instead of DC? I feel like bringing in 5v into the switch and outputting to the relay board would be easier and could use much smaller toggles. I don't have anything rated for 10A as far as toggles go, so I'll probably go that route unless you can think of a reason why I shouldn't?

And for clarification, do D5/D6 go High or Low to engage the relays? Obviously that would change the switching schematic for me.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)