I've been admiring all the basket setups people have been using, but couldn't fathom spending hundreds on one. I've also recently upgraded to a RIMS BIAB configuration and have been having some issues with a stuck recirc.

I started thinking, why can't I create a bag that was fitted well enough to get me some of the benefits of a basket? And the vBIABasket was born! :rockin:

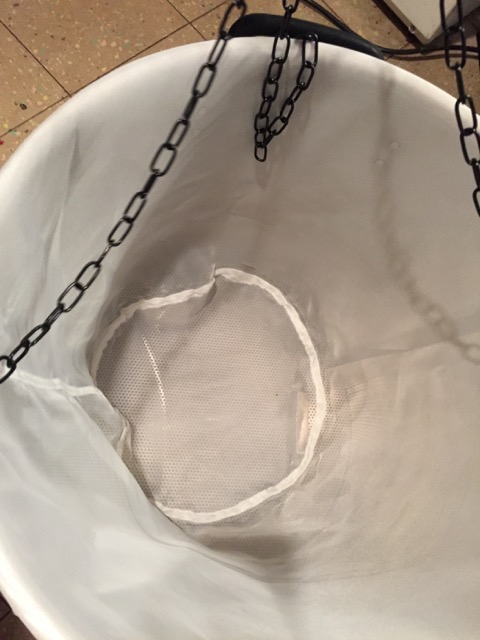

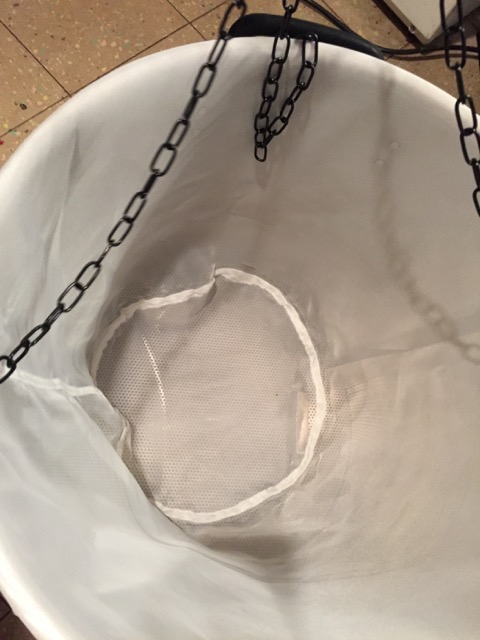

Just finished it up today. Unfortunately I won't have time to try it out for a couple weeks. The basic construction is a viole bag in the fustrum shape from BIABrewer.info. The bag is held in shape by a 3/4" x 1/8" aluminum bar bent into a hoop shape.

The bag is nicely fitted such that there is some space between it and the edges of my pot. This will keep grain from sitting against the outer edges witch will be a little cooler, and provide path for wert to flow. I'll be able to hang the bag and do a pour over sparge.

Can't wait to give it a try! What do you all think? Anything I should watch out for?

I started thinking, why can't I create a bag that was fitted well enough to get me some of the benefits of a basket? And the vBIABasket was born! :rockin:

Just finished it up today. Unfortunately I won't have time to try it out for a couple weeks. The basic construction is a viole bag in the fustrum shape from BIABrewer.info. The bag is held in shape by a 3/4" x 1/8" aluminum bar bent into a hoop shape.

The bag is nicely fitted such that there is some space between it and the edges of my pot. This will keep grain from sitting against the outer edges witch will be a little cooler, and provide path for wert to flow. I'll be able to hang the bag and do a pour over sparge.

Can't wait to give it a try! What do you all think? Anything I should watch out for?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)