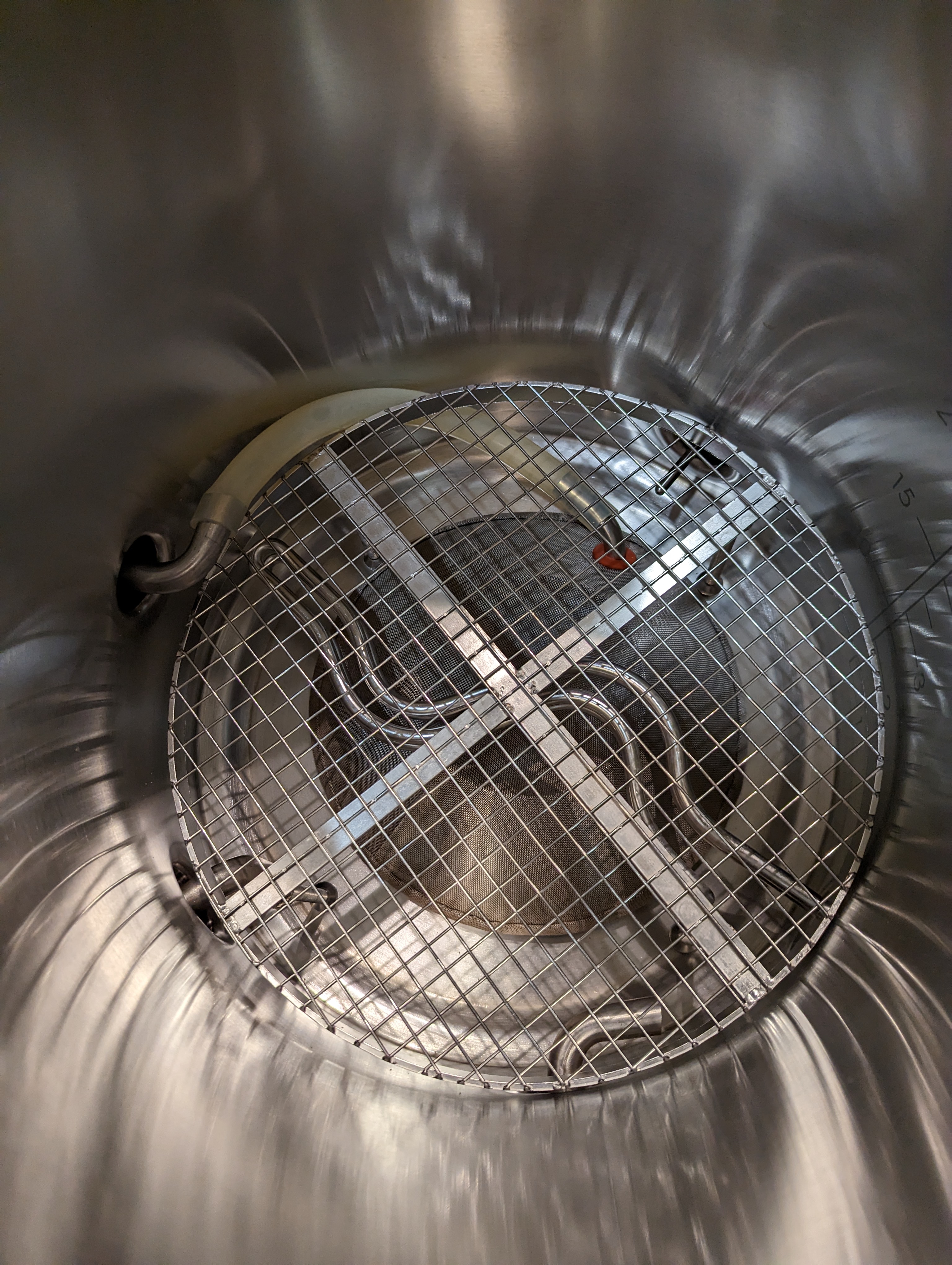

I really appreciate you taking the time to share this build. I have been experimenting with both a spider (no free hops) and a bazooka screen (free hops). So far, the bazooka works the best (labor-wise), but I imagine that the hop blocker would work better based upon what I have already learned from your experience. If you would be so kind, I have one more question/observation.

When you drop the hop blocker, it is going to trap some trub under it. If you then start the whirlpool for your cooling, is it then being pumped out from under the hop blocker into the rest of the boil kettle? While it is whirlpooling, is it actually pre-filtering the wort, in a sense, because the hop blocker is acting as a filter during the whirlpool process?

I'm just trying to wrap my head around the process.

When you drop the hop blocker, it is going to trap some trub under it. If you then start the whirlpool for your cooling, is it then being pumped out from under the hop blocker into the rest of the boil kettle? While it is whirlpooling, is it actually pre-filtering the wort, in a sense, because the hop blocker is acting as a filter during the whirlpool process?

I'm just trying to wrap my head around the process.