stratslinger

Well-Known Member

Jak, when you're very first starting out, you're probably only doing extract, and moving large amounts of fluid from one vessel to another doesn't seem like something you'd do a lot on brew day - except maybe to siphon your chilled wort into your fermenter once you're done boiling and chilling...

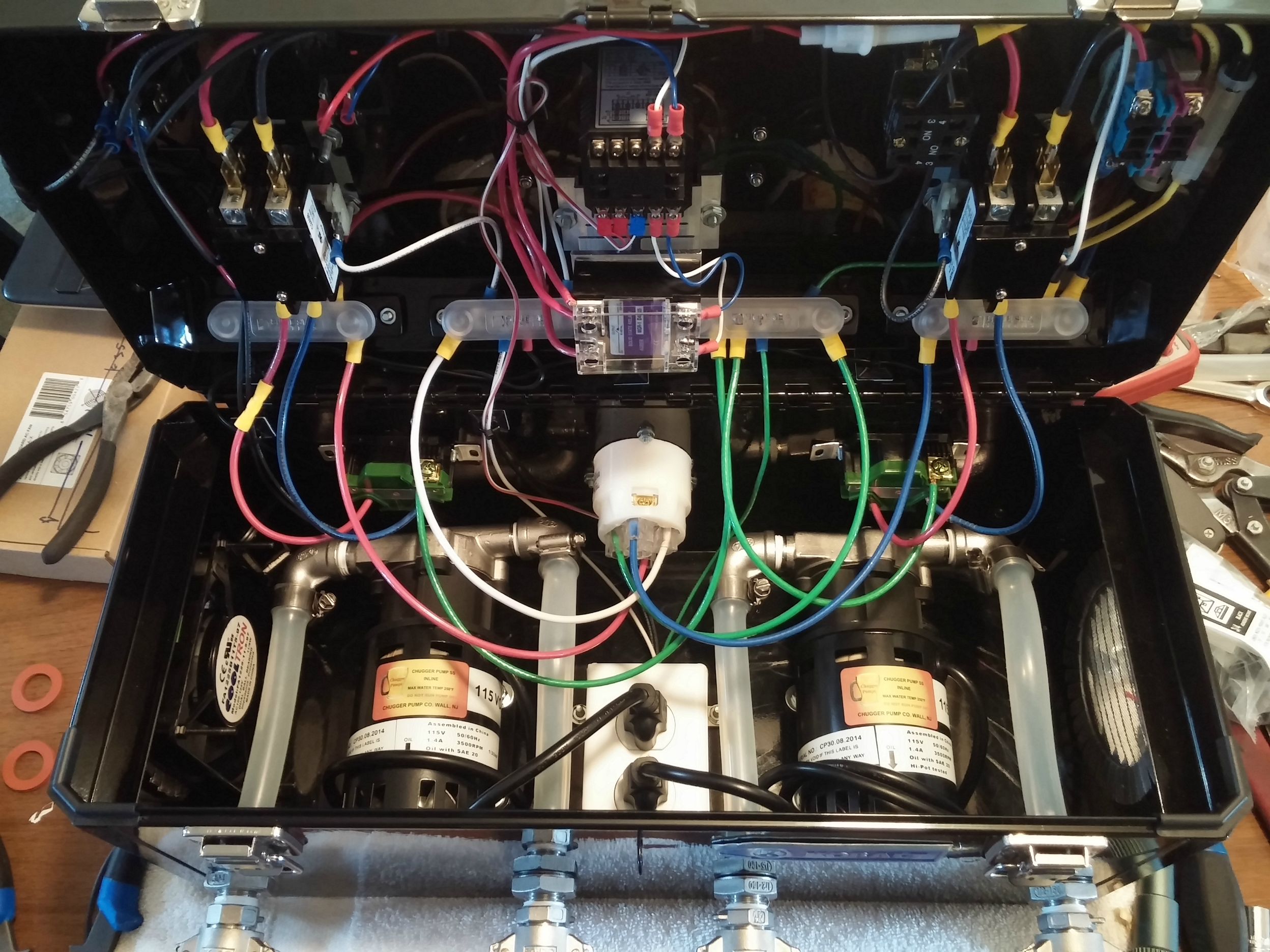

But right now, on a brew day, I use my pump to transfer strike water and sparge water from my HLT into my Mash Tun (terms you'll become familiar with down the road if you choose to pursue all grain brewing). I also use my pump to recirculate boiling wort through my counter flow chiller to sanitize it, and then to push the hot wort through that chiller while actually going through the chilling process.

A bit down the road, I plan to add a RIMS tube like a couple of the guys above have. Basically, that's just a tube with a heating element in it that you constantly circulate the wort from your mash through - this helps maintain the correct mash temperature and the constant recirculation is supposed to add a bit to your mash efficiency. But you need to use your pump to circulate the fluid through that tube, so again, the pump comes into play!

But right now, on a brew day, I use my pump to transfer strike water and sparge water from my HLT into my Mash Tun (terms you'll become familiar with down the road if you choose to pursue all grain brewing). I also use my pump to recirculate boiling wort through my counter flow chiller to sanitize it, and then to push the hot wort through that chiller while actually going through the chilling process.

A bit down the road, I plan to add a RIMS tube like a couple of the guys above have. Basically, that's just a tube with a heating element in it that you constantly circulate the wort from your mash through - this helps maintain the correct mash temperature and the constant recirculation is supposed to add a bit to your mash efficiency. But you need to use your pump to circulate the fluid through that tube, so again, the pump comes into play!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)