Zymurgrafi

Well-Known Member

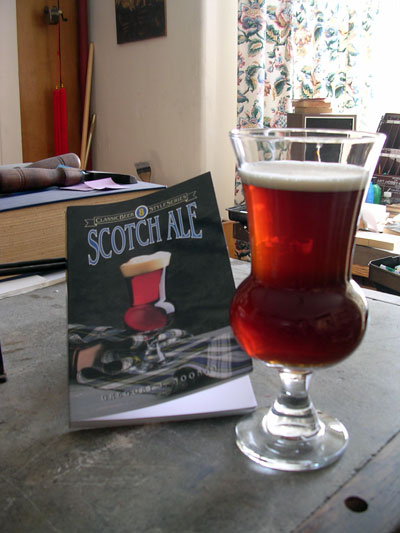

Been wanting to do this for a while now. I have been really into low gravity ales lately brewing milds and bitters. So I figured it was a good time for a succession of shilling ales leading up to a wee heavy.

The plan is to start with a 60/- then pitch a 70/- onto the yeast of that, and so on... Plus harvest and wash some yeast from the 60/- to save for later as it is difficult for me to get good liquid yeast and I am a skinflinty bastid'. Bit o' the Scottish runnin' in these veins + the yankee...

I have done an 80/- and a Scotch ale but never a full procession. For this one I am going to scrap the previous recipes I made and try the most simple "allegedly" traditional method. That being simply to use Marris Otter and a bit of roasted barley for color. Caramelizing the first gallon of runnings then a 120 minute boil for a malty thick brew. Then just a bit of Goldings for balance. Ferment her cool in my basement at about 60-62F then condition cold as I can (hopefully low 50's) for a few weeks.

Starter of Wyeast 1728 is going...

I realize with a starting gravity of only 1.031 I could probably get away without a starter, but what the hell...

Now it is just a matter of scrounging some time to brew. Wife owes me one the way I see it. Had the kids all alone for 4 days last week when she went to a conference. :cross:

I need a break!

The plan is to start with a 60/- then pitch a 70/- onto the yeast of that, and so on... Plus harvest and wash some yeast from the 60/- to save for later as it is difficult for me to get good liquid yeast and I am a skinflinty bastid'. Bit o' the Scottish runnin' in these veins + the yankee...

I have done an 80/- and a Scotch ale but never a full procession. For this one I am going to scrap the previous recipes I made and try the most simple "allegedly" traditional method. That being simply to use Marris Otter and a bit of roasted barley for color. Caramelizing the first gallon of runnings then a 120 minute boil for a malty thick brew. Then just a bit of Goldings for balance. Ferment her cool in my basement at about 60-62F then condition cold as I can (hopefully low 50's) for a few weeks.

Starter of Wyeast 1728 is going...

I realize with a starting gravity of only 1.031 I could probably get away without a starter, but what the hell...

Now it is just a matter of scrounging some time to brew. Wife owes me one the way I see it. Had the kids all alone for 4 days last week when she went to a conference. :cross:

I need a break!