Small_Batch

Active Member

SOOO I got bored this summer and decided to attack a new project. My very own, one of a kind, cedar lined temperature controlled fermentation box!! WOOHOOO!! :rockin:

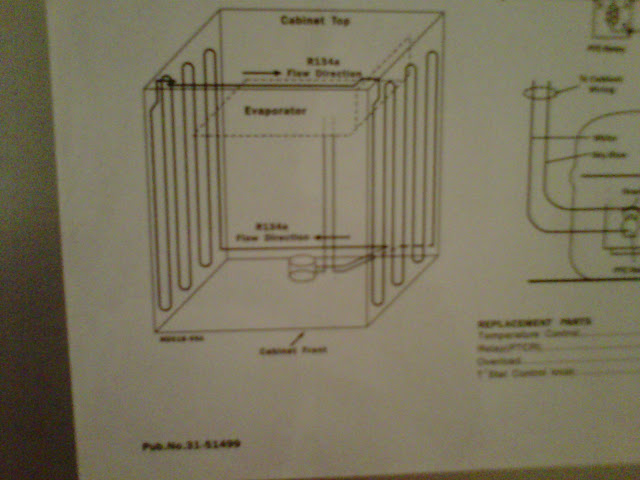

This post will display how I took this:

Into this:

Unfortunately, this isn't a completely finished picture. It is missing wood sealer & hardware. THe final reveal will be soon! I promise!

This post will display how I took this:

Into this:

Unfortunately, this isn't a completely finished picture. It is missing wood sealer & hardware. THe final reveal will be soon! I promise!