Antonio Martinez

Well-Known Member

- Joined

- Apr 14, 2018

- Messages

- 133

- Reaction score

- 83

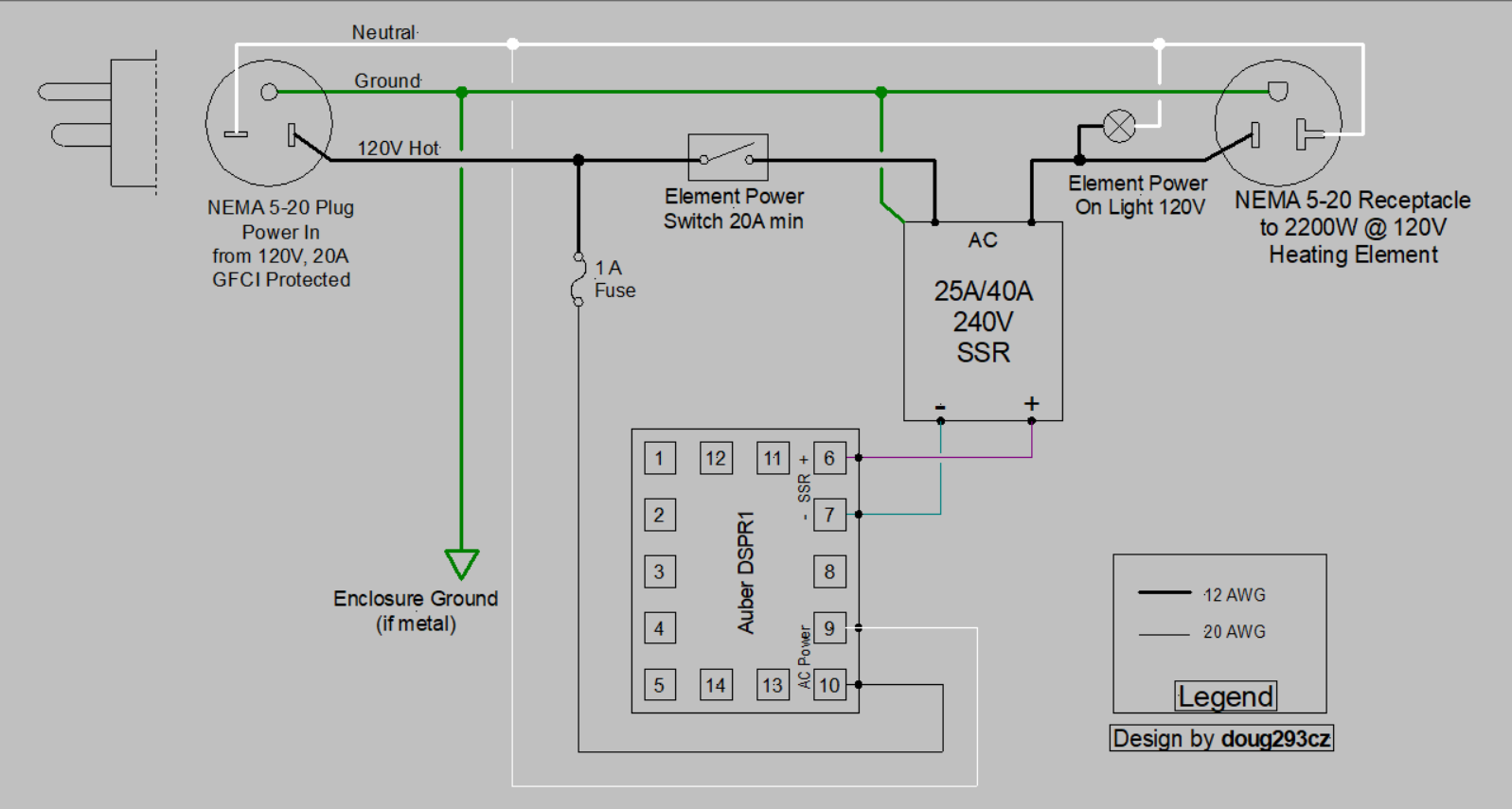

Looking for a double check on the layout/wiring. The system will be a 120v 2200w control panel based on DSPR1 controller from Auber. This will be plugged into a dedicated 20a GFCI protected circuit and will not run anything else (i.e. no pump outlet in the control panel). The heatsink for the SSR is actually going to be oversized and intended for 40a SSR but in the event an upgrade is done I'm trying to cut down on the parts needing to be replaced. All wiring will be 12 awg wire for simplicity even though I understand smaller gauge wire could be run to the DSPR itself. I am also planning to use terminal strips rated to 30a 600v as hot, neutral, ground bus bars to simplify wiring and make it easier to add any future connections. Jumper wires will be used to make connections between lugs on the bus bars.

Cheers

Cheers