looks good to me. How much higher did you make your legs in order to put the kegs under there? you think the controls on the back side and low are going to be an issue for adjustments? Damn, I sure like this non-welding structure... I'm so confused...

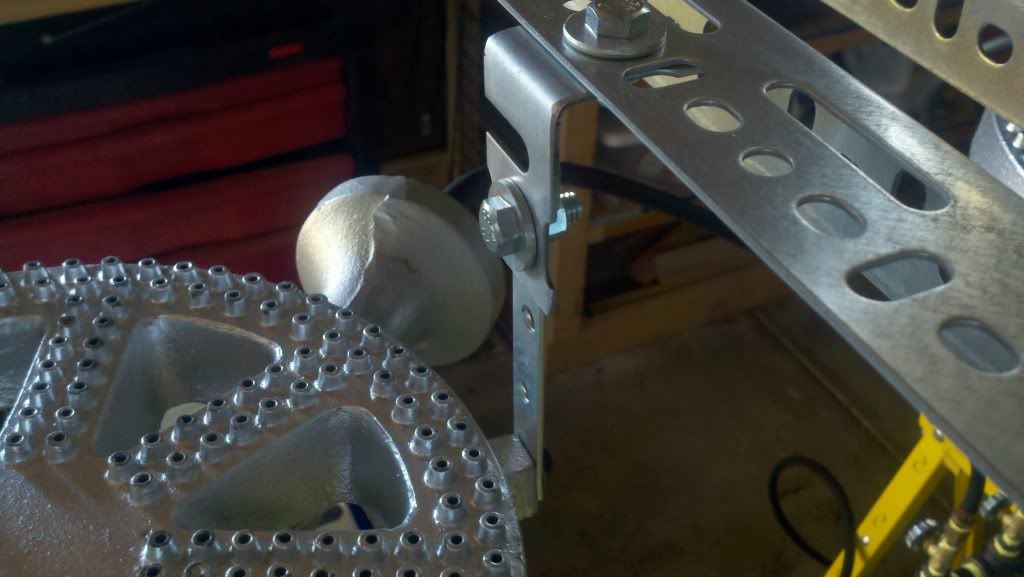

The original design specifies 21" legs, I had to cut mine to 33" to account for the height of the keg + thickness of the entire burner + 4" clearance from top of burner to the bottom of the keggles + an extra inch or so of room to jimmy the keggles underneath for storage. The pic above is actually of the back of the brew rig... I didn't want to put the manifold on the front of the stand... aesthetic purposes I guess. Here is a pic of the front of my rig... all that's left to do is mount my drain valves, thermos, and sight tubes onto the 3 keggles.