burnninator

Member

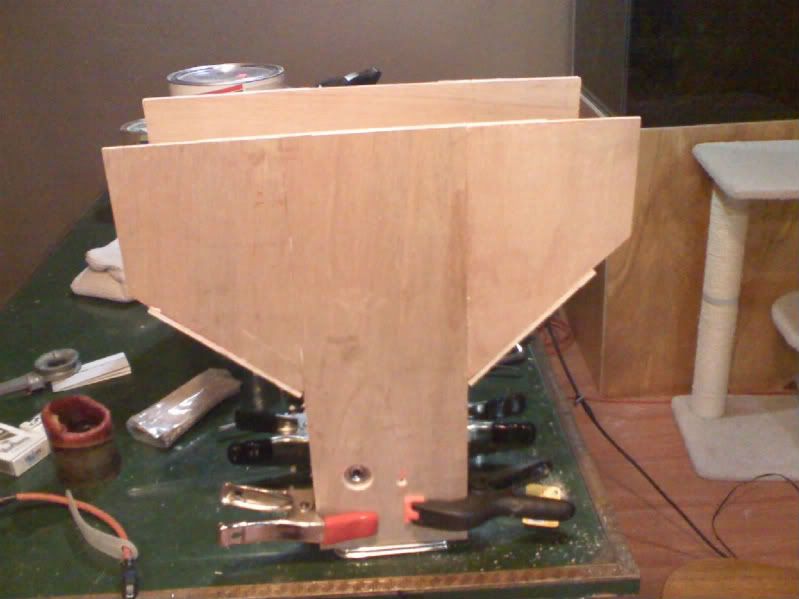

Started on my pasta crusher today. Here's what I have done so far.

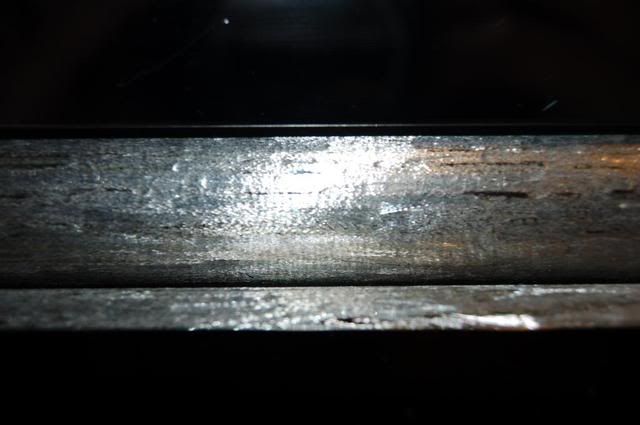

I used my Dremel to add texture to the rollers so it would grab the grain. Here is the grinder attachment I used. I just took the whole thing apart and grinded the rollers until they were completely textured.

Here is a close up of the texture on the roller.

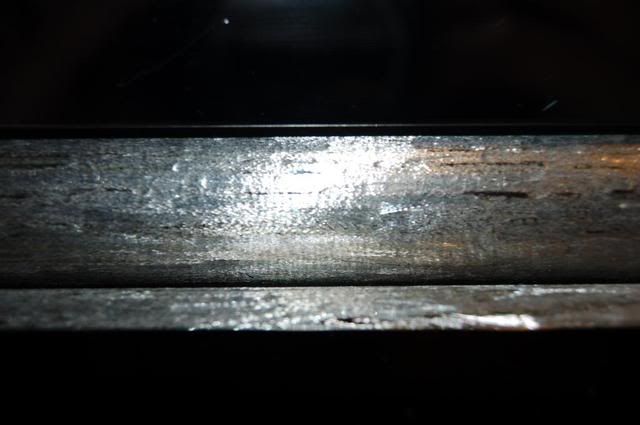

And here is a close up of the result using it on the "7" setting. Anything smaller than the "5" setting pulverizes the grain to nothingness.

I need to make a hopper and a bucket attachment.

I am new to all grain and have actually never seen what crushed grain looks like. Can someone give me some feedback on if what I have looks alright?

I used my Dremel to add texture to the rollers so it would grab the grain. Here is the grinder attachment I used. I just took the whole thing apart and grinded the rollers until they were completely textured.

Here is a close up of the texture on the roller.

And here is a close up of the result using it on the "7" setting. Anything smaller than the "5" setting pulverizes the grain to nothingness.

I need to make a hopper and a bucket attachment.

I am new to all grain and have actually never seen what crushed grain looks like. Can someone give me some feedback on if what I have looks alright?

I think I'll go pick them up tonight and see how they work.

I think I'll go pick them up tonight and see how they work.