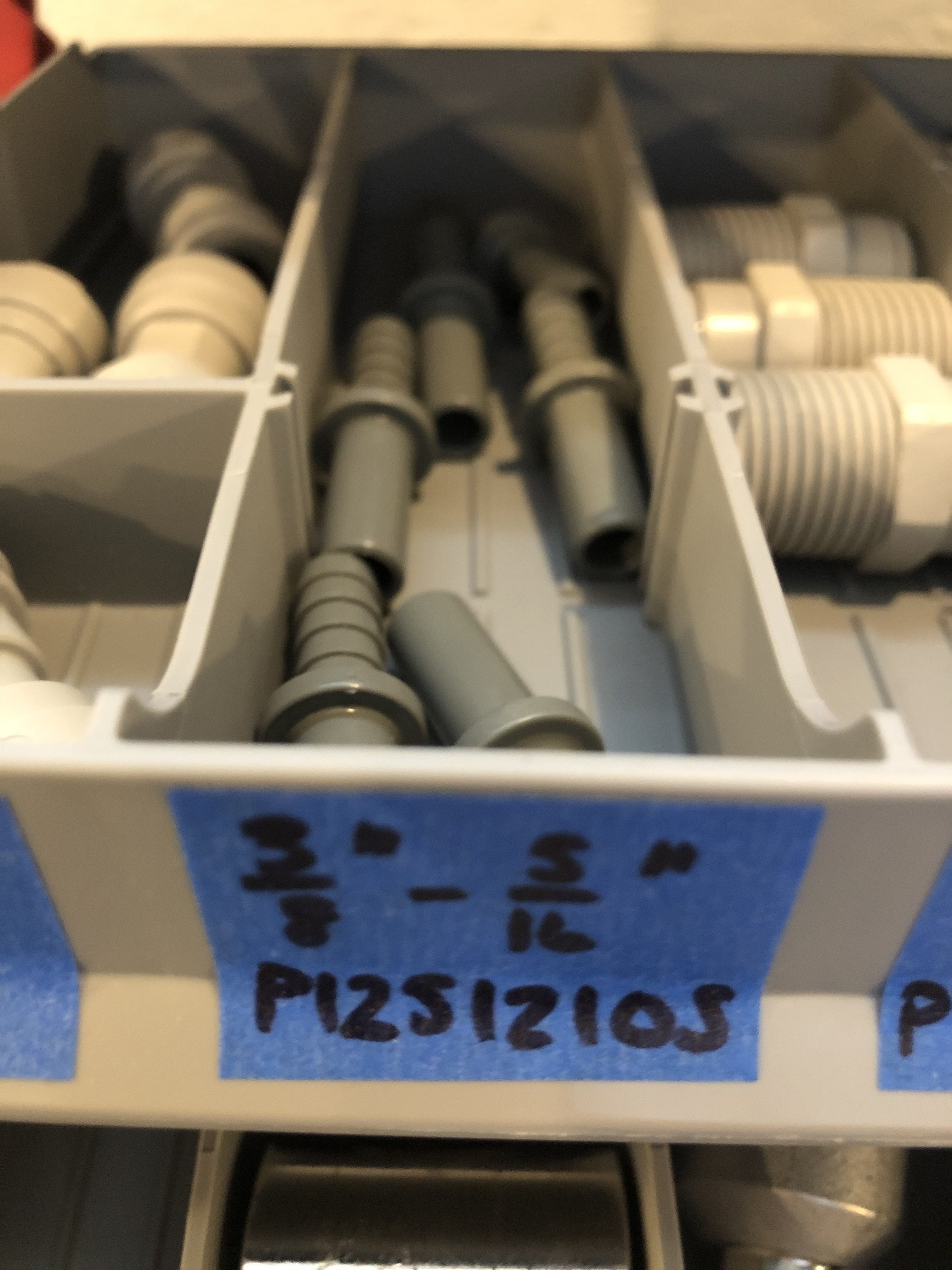

I'm switching out all of my gas lines to barrier tubing, since I have a ton of the stuff so I might as well use it to keep oxygen out of the gas lines as well. To make this easier, I'm switching my connectors to John Guest connectors.

However, I'm struggling to unscrew the gas in barb on my Taprite secondary. The gas out barbs and gauges came off fairly easily, but the gas in barb seems to be glued in

Any suggestions how to get it loose? Heat it a bit to melt whatever is keeping it in? Or just try to exert more force?

However, I'm struggling to unscrew the gas in barb on my Taprite secondary. The gas out barbs and gauges came off fairly easily, but the gas in barb seems to be glued in

Any suggestions how to get it loose? Heat it a bit to melt whatever is keeping it in? Or just try to exert more force?