thereverendmaynard

Well-Known Member

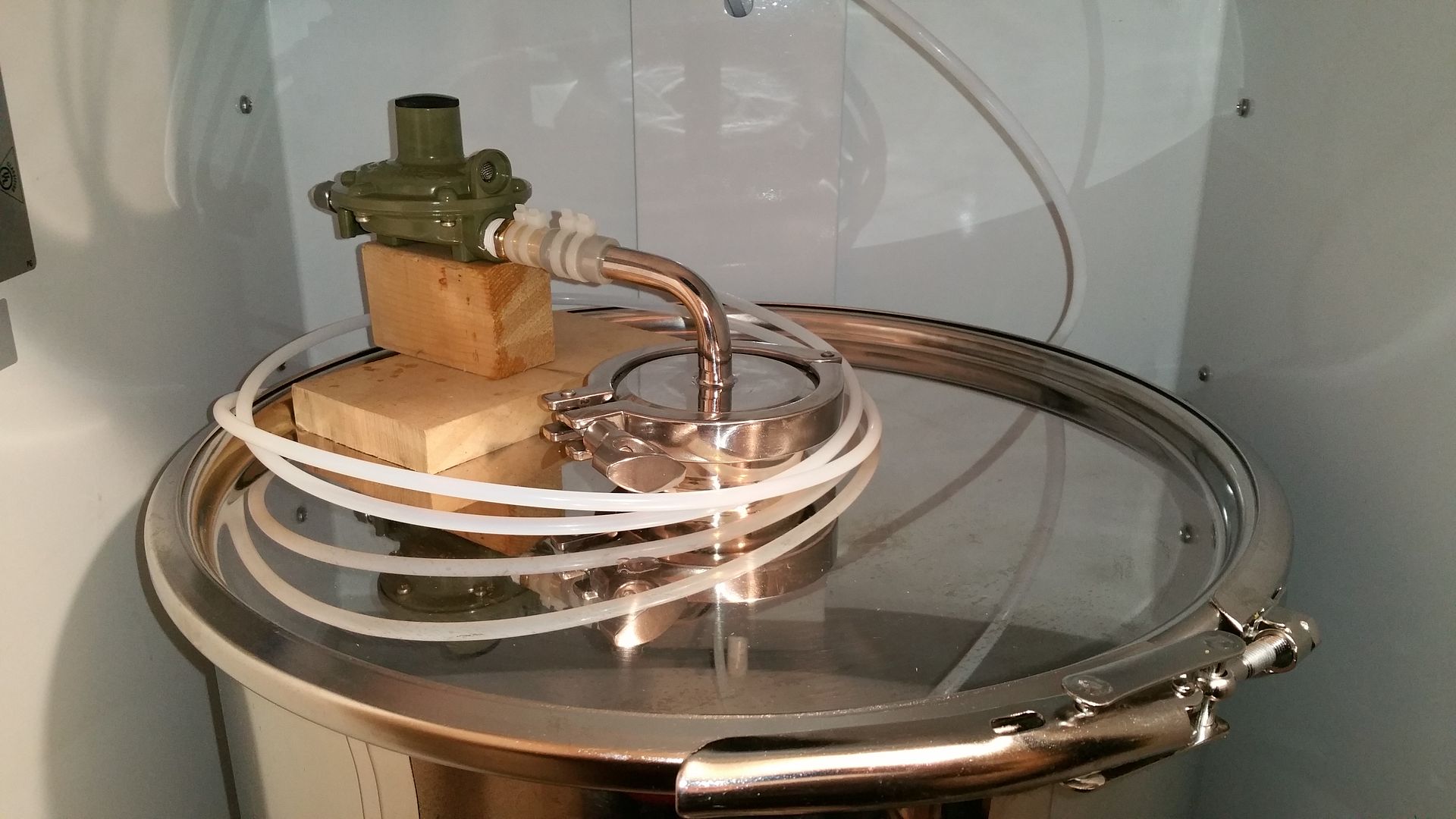

I dropped temp in my temp chamber for a cold crash for a session rye ipa. Set for 34f.

Hit my set point, but when i looked into the chamber - there was only an ice crust in the container i put the sanitizer in (starsan). Looks like it got sucked into the fermentor. Looks about 1qt of sanitizer got sucked in.

10 gallon batch.... Is my batch ruined? So bummed :-(

Hit my set point, but when i looked into the chamber - there was only an ice crust in the container i put the sanitizer in (starsan). Looks like it got sucked into the fermentor. Looks about 1qt of sanitizer got sucked in.

10 gallon batch.... Is my batch ruined? So bummed :-(