corneyl

Member

- Joined

- Mar 22, 2017

- Messages

- 5

- Reaction score

- 1

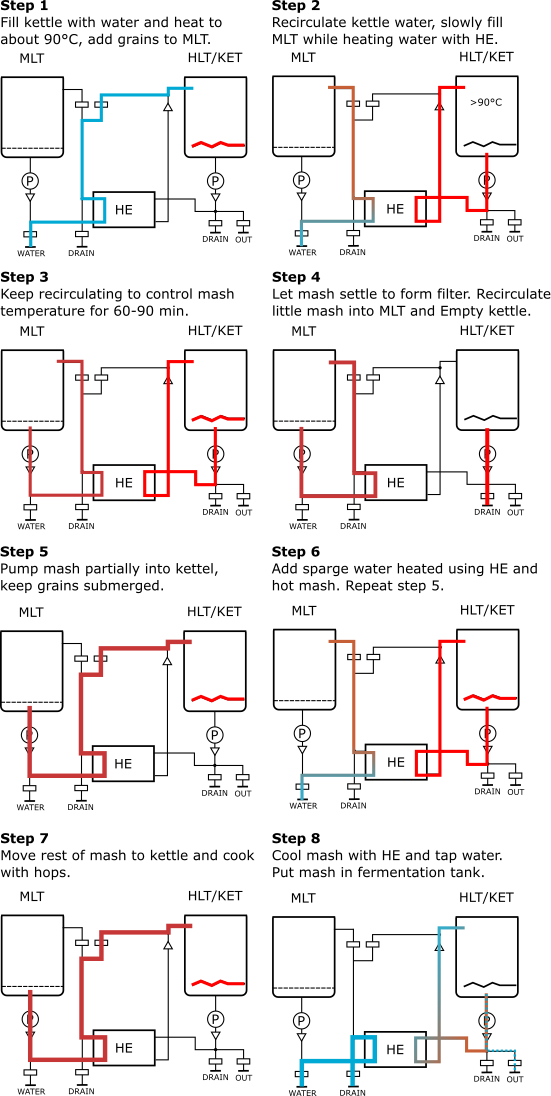

Most HERMS systems use a 3-vessel system, but I was wondering whether it's also possible to do it with 2 vessels. I couln't find a lot of info on this. But one needs less valves, just two vessels, but a separate heat exchanger, so it could be more cost effective. A disadvantage is that sparging is harder to do, see the attachment for my idea.

As far as I understood the process, with these 8 steps it should be possible to brew a beer. In step 5 I add the sparge water while the mash water (is that the correct term?) is still in the pot. So sparging probably works out a bit less effective, but still better than no sparging at all.

In total I would need two vessels, a heat exchange, two pumps and 8 valves.

Do you guys think that this would work out ok? Has anyone (used) a 2V-HERMS?

BTW: please correct me if I'm using wrong terms, beginner here

As far as I understood the process, with these 8 steps it should be possible to brew a beer. In step 5 I add the sparge water while the mash water (is that the correct term?) is still in the pot. So sparging probably works out a bit less effective, but still better than no sparging at all.

In total I would need two vessels, a heat exchange, two pumps and 8 valves.

Do you guys think that this would work out ok? Has anyone (used) a 2V-HERMS?

BTW: please correct me if I'm using wrong terms, beginner here