Welcome to my second build thread on this site. I didn't really plan on making another one of these since I was truly happy with my old brew system, however changes in my life have forced me to part ways with it and downsize. This was my old system Build thread located here if you want to see how it was working. I will soon be living in a tiny house (yes like the show on wheels etc) so the new system will need to meet several new requirements and since I just parted out my old system we have a decent brewing budget to make what I think will be "The Ultimate BIAB system..." whatever that means.

Requirements for the new system are as follows

I have placed an order for my kettle already and it should be here this week. (bling bling)

These are my current plans, that will probably change so feel free to toss in your experience, questions and awesome sauce ideas.

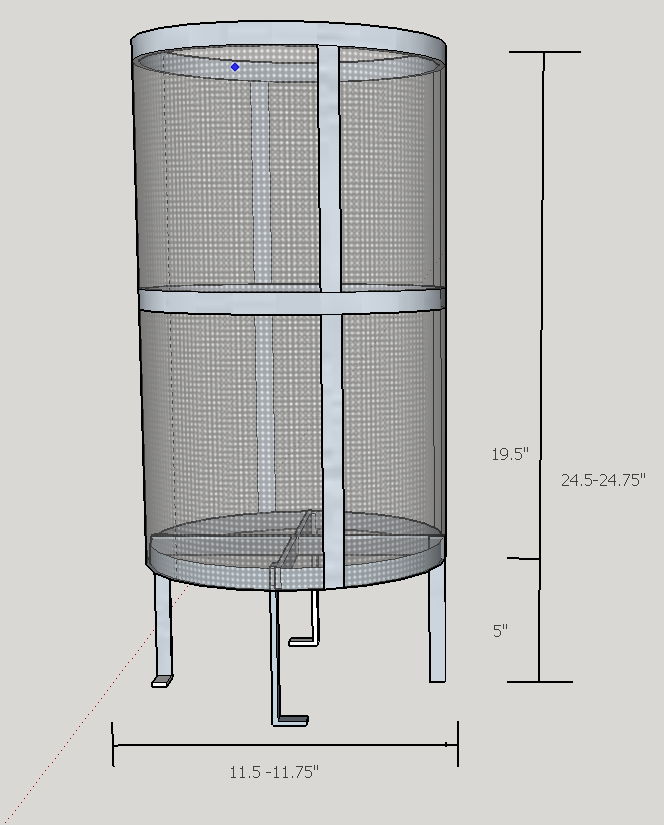

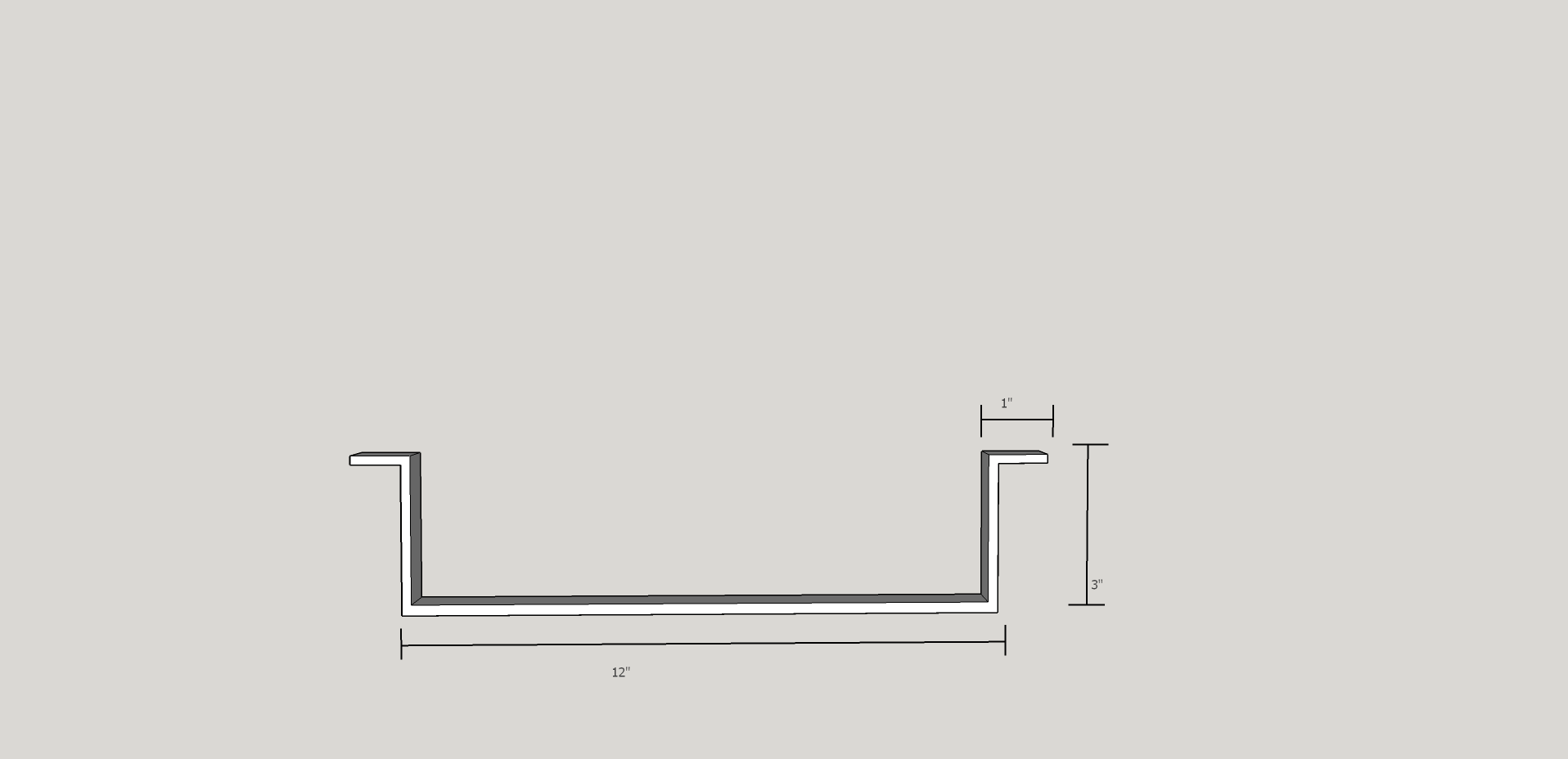

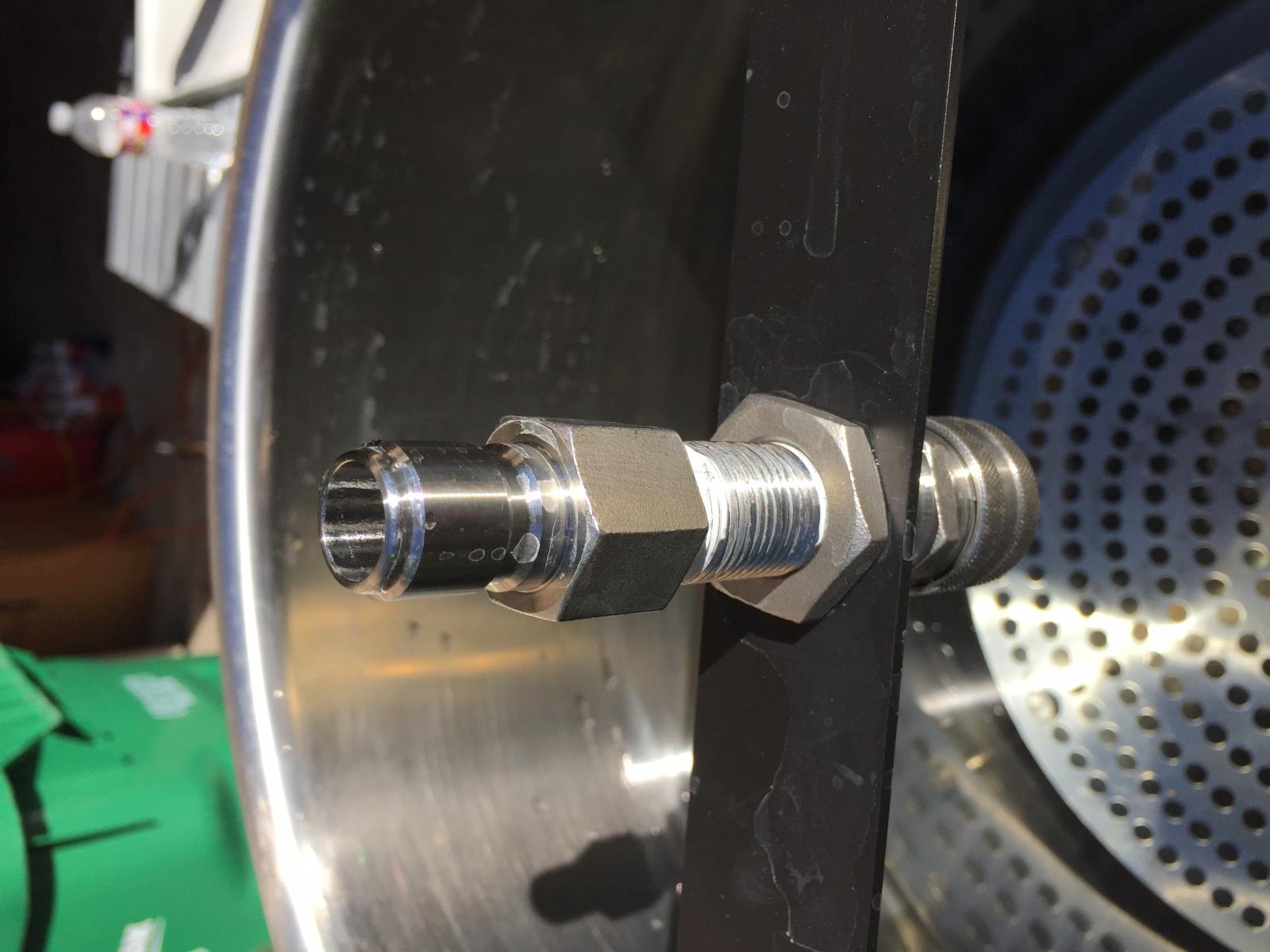

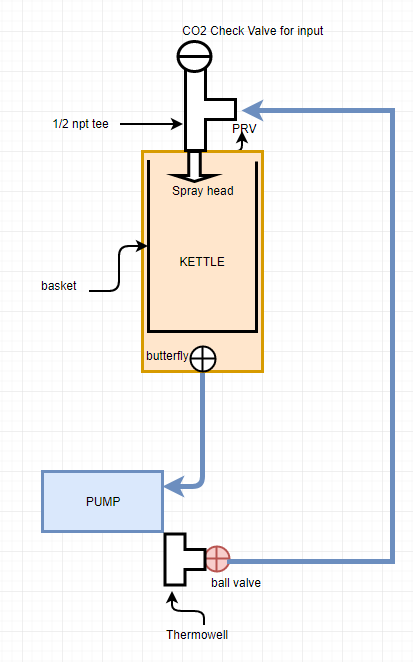

For the mash, nothing super magic. Basket with element underneath, recirc to maintain even temps. The system will have a spray head and will be able to be purged with CO2 to eliminate any concern of HSA from spray head.

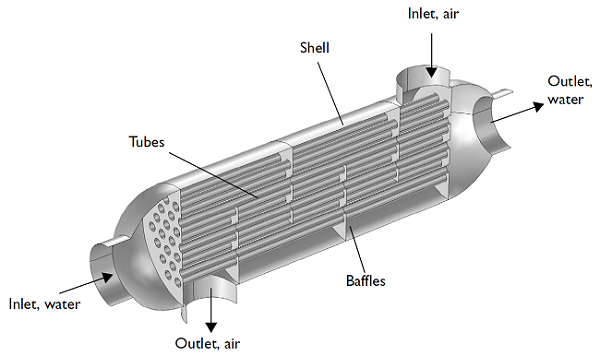

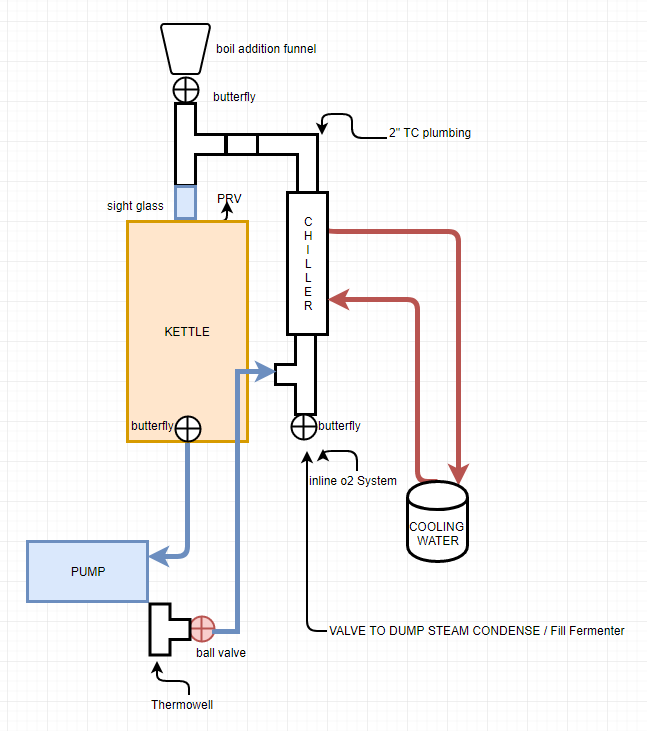

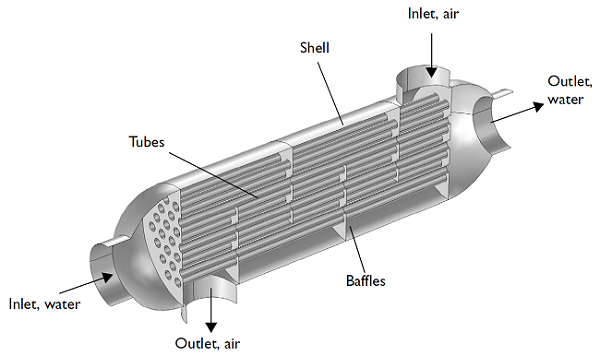

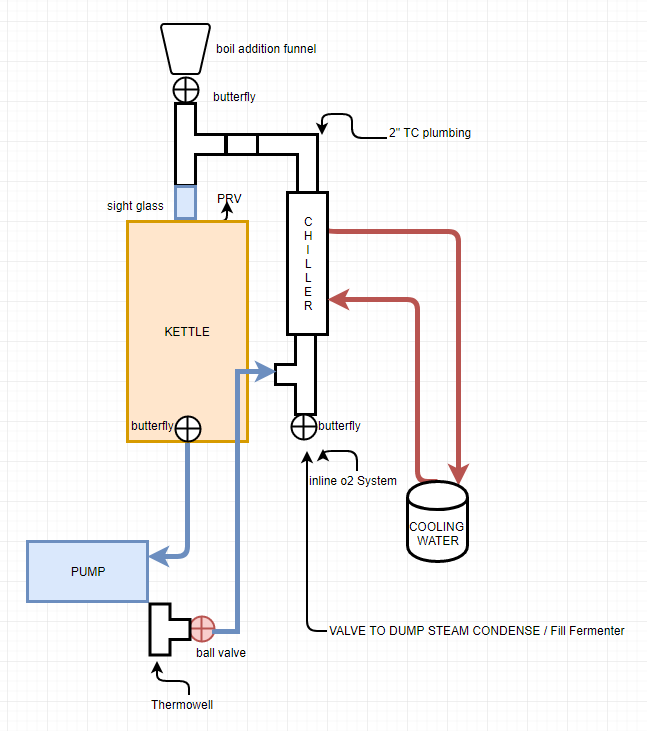

After the mash, we will remove the basket and this is where the magic happens. The plan is to use a condenser unit for the steam. *mind blown* ... Seriously though this is going to be baller. This takes care of the not making a ton of steam in the house and should eliminate most the smells on brew day from the boil. I thought using a condenser was a cool invention of mine but it turns out plenty of breweries do this already. Example

However, we are going to take it one step further and use the condenser as the wort chiller at the end of the boil too. I think a pool heat exchanger will work awesome for this. Honestly not sure why these are not more common in general as counterflow wort chillers considering you can get a stainless unit for around $100

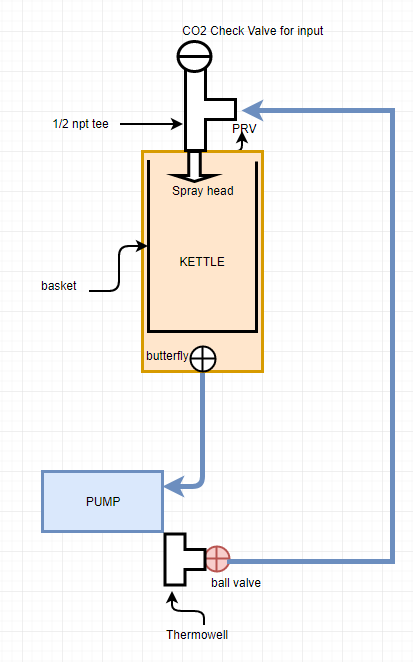

So this is what I'm thinking the boil / cooling loop will look like.

The system will have the bottom butterfly open to let the distillate drop out into the sink or w/e i drain it. when hop additions are ready. there will be a drop funnel with butterfly valve on top I can swing open then close. This system also gives me the ability to basically boil with the lid on, so I should be able to hold a decently strong boil with a 1650w element. I will most likely be making my own brewery controller from an RPI this time around. The BCS was pretty awesome but I think I can do the same thing for a lot cheaper myself. Anyway I look forward to logging this thing with everyone and sharing ideas.

Requirements for the new system are as follows

- Bling Bling Fancy

- Run on 110v 15amp circuit Decided to go 220v

- Make 5 gallon High gravity batches

- Make no steam

- Not smell up the house (wife requirement)

- Easy to clean

- Low O2 brewing

- Easy to use

- PID mash and boil control.

- Temp Logging / Web Interface

- Boil controller double as ferm controller

I have placed an order for my kettle already and it should be here this week. (bling bling)

These are my current plans, that will probably change so feel free to toss in your experience, questions and awesome sauce ideas.

For the mash, nothing super magic. Basket with element underneath, recirc to maintain even temps. The system will have a spray head and will be able to be purged with CO2 to eliminate any concern of HSA from spray head.

After the mash, we will remove the basket and this is where the magic happens. The plan is to use a condenser unit for the steam. *mind blown* ... Seriously though this is going to be baller. This takes care of the not making a ton of steam in the house and should eliminate most the smells on brew day from the boil. I thought using a condenser was a cool invention of mine but it turns out plenty of breweries do this already. Example

However, we are going to take it one step further and use the condenser as the wort chiller at the end of the boil too. I think a pool heat exchanger will work awesome for this. Honestly not sure why these are not more common in general as counterflow wort chillers considering you can get a stainless unit for around $100

So this is what I'm thinking the boil / cooling loop will look like.

The system will have the bottom butterfly open to let the distillate drop out into the sink or w/e i drain it. when hop additions are ready. there will be a drop funnel with butterfly valve on top I can swing open then close. This system also gives me the ability to basically boil with the lid on, so I should be able to hold a decently strong boil with a 1650w element. I will most likely be making my own brewery controller from an RPI this time around. The BCS was pretty awesome but I think I can do the same thing for a lot cheaper myself. Anyway I look forward to logging this thing with everyone and sharing ideas.