dustthisnsx

Member

Perhaps a long-running fault of mine.....but I've always turned to CL for deals over retail. Whether that be car parts, paintball ish, gun stuff or even brewing stuff... I can't help it! But like anything CL you should be ready to put some work into it to bring it back to life. Follow along if you want to see and contribute some much-needed input on a glycol build!

So a touch of background, skip if you like pictures I've been brewing out of buckets for 10+years but a recent accident pushed me to look at how I can reduce lifting during brewing and fermentation. I chart pH and gravity slopes daily on new beers and lifting buckets from of a deep freeze was no longer an option. Looked at the conical and brew bucket options out there as casters seemed like a simple way to roll wort from the brew stand. BUT they are bloody expensive new! Turned to the used market and stumbled on some SS 7g w/ blowoff units from the Dallas area for $200 each and settled on $350 for the pair. Totes would have been $40 and grayhound an additional $80 for the pair. not a bad deal at all but this would have have been 2X every part and dual FTSs... $$$ Then I stumbled on a Blichmann 14g for $300 even, SOLD.

I've been brewing out of buckets for 10+years but a recent accident pushed me to look at how I can reduce lifting during brewing and fermentation. I chart pH and gravity slopes daily on new beers and lifting buckets from of a deep freeze was no longer an option. Looked at the conical and brew bucket options out there as casters seemed like a simple way to roll wort from the brew stand. BUT they are bloody expensive new! Turned to the used market and stumbled on some SS 7g w/ blowoff units from the Dallas area for $200 each and settled on $350 for the pair. Totes would have been $40 and grayhound an additional $80 for the pair. not a bad deal at all but this would have have been 2X every part and dual FTSs... $$$ Then I stumbled on a Blichmann 14g for $300 even, SOLD.

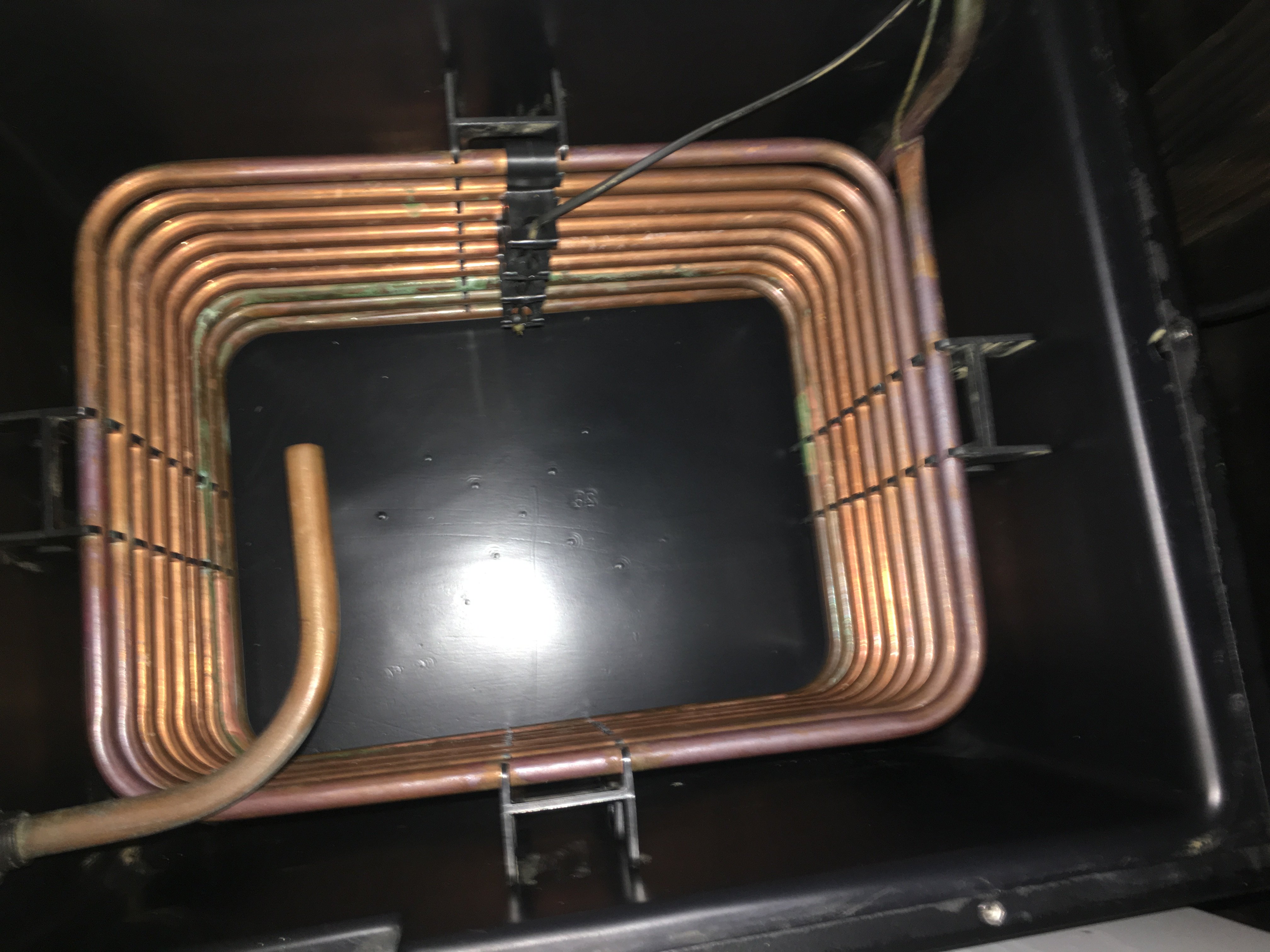

Next up was the glycol chiller. Lots of DIY options and then there are homebrew specific ones from $800 penguin or ss brew tech units above the 1K mark. Couldn't justify that kind of coin, so back to CL. Found a number of MicroMatic and UBC units but still well above $500. Then I stumbled over a Tafun H35G 1/3hp Procom 125ft run unit on OfferUp which was recently reduced from $600 to $300, offered $225 and got a bit! Took a look at it and it was MINT! These systems are typically used in a taproom where the taps are with remote cold storage or in this case, a past life at Jamba Juice.

Now for the FUN part in combining these two units! GOALS are to utilize this for regulating 14g conical fermentation temps at ale, lager and cold crash temps as well possibly cool a trunk line of just a few feet from a fridge outside the garage to taps inside. The only other brewing application I've seen of this unit was chilling a 3bbl conical... and that looked to have had big 1/2 lines. I'll post if I can locate the post again. If my math is correct the SS systems are just about 2,000 btu/hr and the pump does 10L/min or 41g/hr whereas this does a minimum of 90g/hr at 2600btu/hr! Like I said, overkill and overpressure! But how to reduce the flow and pressure? Thus far, I've yet to attempt anything but the possible options as I see it are as follows. Let me know if you have a better idea!

- abandon the large pump and buy a SS Brew Tech or a similar submersible pump. Abandon is a harsh word as I'd likely repurpose it for a canner

- somehow slow the motor driving the pump

- add a restrictive oriface in line (assuming the pumps bypass can handle that much backpressure)

For temp control, I'd likely try and mirror the programming of the FTS with an existing STS-1000 I have and adding a side mounted FTS coil to the conical. Let me know your thoughts! Until then, I'll be brewing Kveiks w/o any temp control!

So a touch of background, skip if you like pictures

Next up was the glycol chiller. Lots of DIY options and then there are homebrew specific ones from $800 penguin or ss brew tech units above the 1K mark. Couldn't justify that kind of coin, so back to CL. Found a number of MicroMatic and UBC units but still well above $500. Then I stumbled over a Tafun H35G 1/3hp Procom 125ft run unit on OfferUp which was recently reduced from $600 to $300, offered $225 and got a bit! Took a look at it and it was MINT! These systems are typically used in a taproom where the taps are with remote cold storage or in this case, a past life at Jamba Juice.

Now for the FUN part in combining these two units! GOALS are to utilize this for regulating 14g conical fermentation temps at ale, lager and cold crash temps as well possibly cool a trunk line of just a few feet from a fridge outside the garage to taps inside. The only other brewing application I've seen of this unit was chilling a 3bbl conical... and that looked to have had big 1/2 lines. I'll post if I can locate the post again. If my math is correct the SS systems are just about 2,000 btu/hr and the pump does 10L/min or 41g/hr whereas this does a minimum of 90g/hr at 2600btu/hr! Like I said, overkill and overpressure! But how to reduce the flow and pressure? Thus far, I've yet to attempt anything but the possible options as I see it are as follows. Let me know if you have a better idea!

- abandon the large pump and buy a SS Brew Tech or a similar submersible pump. Abandon is a harsh word as I'd likely repurpose it for a canner

- somehow slow the motor driving the pump

- add a restrictive oriface in line (assuming the pumps bypass can handle that much backpressure)

For temp control, I'd likely try and mirror the programming of the FTS with an existing STS-1000 I have and adding a side mounted FTS coil to the conical. Let me know your thoughts! Until then, I'll be brewing Kveiks w/o any temp control!

Last edited: