Pale Ales and Such

Well-Known Member

- Joined

- Mar 7, 2021

- Messages

- 88

- Reaction score

- 40

Hello all,

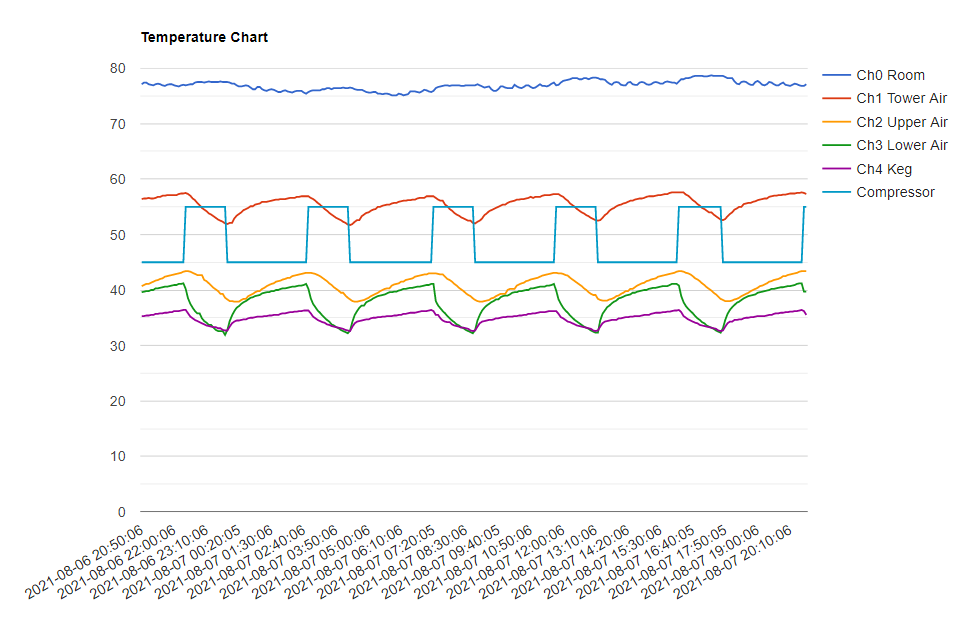

I just got the inkbird ITC-308 and I’m currently testing it out. It works great but when the cooling temp is reached, where the inkbird does shut off the keezer, the keezer will run a few more minutes and the temp drops about 12 degrees lower than where I want it to be.

what’s a good solution to this problem? I was looking at possibly getting a heating element of some kind but wasn’t sure what would work great for a keezer.

thanks!

I just got the inkbird ITC-308 and I’m currently testing it out. It works great but when the cooling temp is reached, where the inkbird does shut off the keezer, the keezer will run a few more minutes and the temp drops about 12 degrees lower than where I want it to be.

what’s a good solution to this problem? I was looking at possibly getting a heating element of some kind but wasn’t sure what would work great for a keezer.

thanks!