Lumpyyyyy

Well-Known Member

Where does the end of your tubing go? Do you have a fitting in the kettle or in the lid?

Where does the end of your tubing go? Do you have a fitting in the kettle or in the lid?

Augiedoggy, the contactor rewiring worked for the element, however, the switch light was always on. So I disconnected the neutral wire going into X1 on the element switch and then it didn't light at all. A little perplexed as to how to wire that switch so it will come on when the element is on and in the on position?Yes Exactly, this would function correctly.

I'm not familiar with that switch from auber and assume you need the nuetral to go to the switch still to power the led if its 120v...

Augiedoggy, the contactor rewiring worked for the element, however, the switch light was always on. So I disconnected the neutral wire going into X1 on the element switch and then it didn't light at all. A little perplexed as to how to wire that switch so it will come on when the element is on and in the on position?

Augiedoggy, the contactor rewiring worked for the element, however, the switch light was always on. So I disconnected the neutral wire going into X1 on the element switch and then it didn't light at all. A little perplexed as to how to wire that switch so it will come on when the element is on and in the on position?

Honestly that shouldnt be happening if you power is really being killed to the coil the power should also be removed to the led since its coming across the same switch contacts right? but if run the yellow wire to contact# 13 then run a jumper wire from #14 to x1.... that should make the led come on and off with the switch mechanism by cutting the neutral when its off. ...

But there is power to one of the alarm terminals, even when the PID is off, unless I'm missing something. Any reason not to put the timer on the same switch as the PID, and switch both alarm powers thru that switch as well?

Brew on

View attachment 235535

Success. Tested with 5 gals of water at 58 degrees.

05 mins - 94 (incr of 36 degrees)

10 mins - 137 (incr of 43 degrees)

15 mins - 185 (incr of 38 degrees)

That's a projected boil time of less than 20 mins. Happy with results. Thanks to all who provided input and questions.

Sent from my iPhone using Home Brew

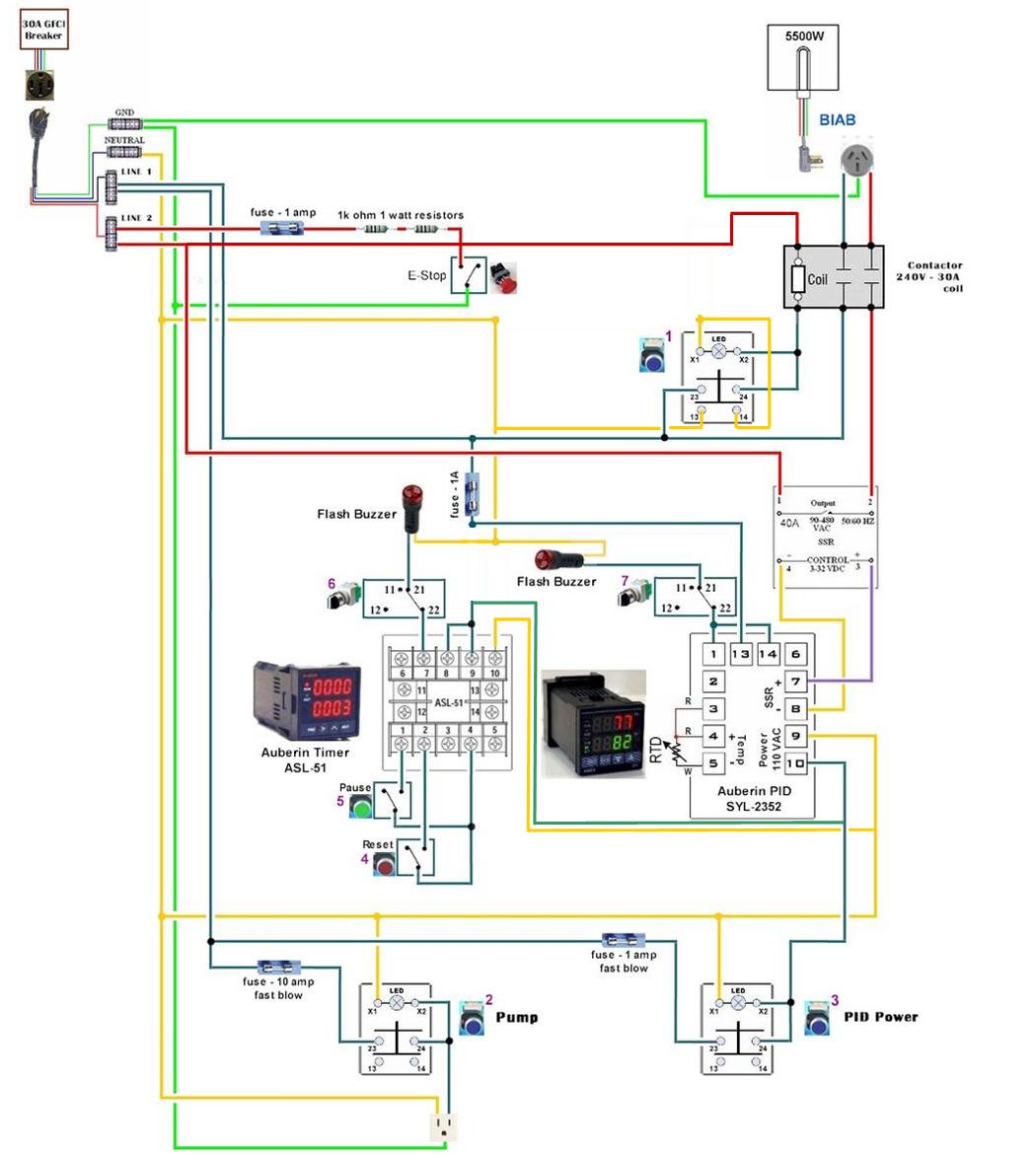

This is just my documentation of the wiring changes I had to make to address the two issues, the timer power being always on and the modification to use the 240v coil contactor (thanks to augiedoggy, bsperr and doug293cz). This is NOT the original schematic I started with, just the end result for anyone who runs into a similar issues. Will update for the first brew

a little olive oil on the element base stopped the rusting for me but some use silicone... I'm not sure if anyone makes a stainless based ULWD element lots of lwd ones available but they are not ideal for BK use...View attachment 237706

Well, it works and I was able to successfully able to brew Kolsch but a couple glitches I need to work out. One of those is not being able to get the PID to go into manual mode. Brewing on automatic mode at 100% power is not effective for maintaining a controlled boil. Also, hind sight 20/20, I wouldn't have installed a timer. Using BeerSmith I haven't used it and probably won't. Also, I noticed the heating element block that holds the coil inside the kettle had a rust film on the face after the water test. Might be changing that to something with a stainless block.

Sent from my iPhone using Home Brew

Enter your email address to join: