urbangravity

Well-Known Member

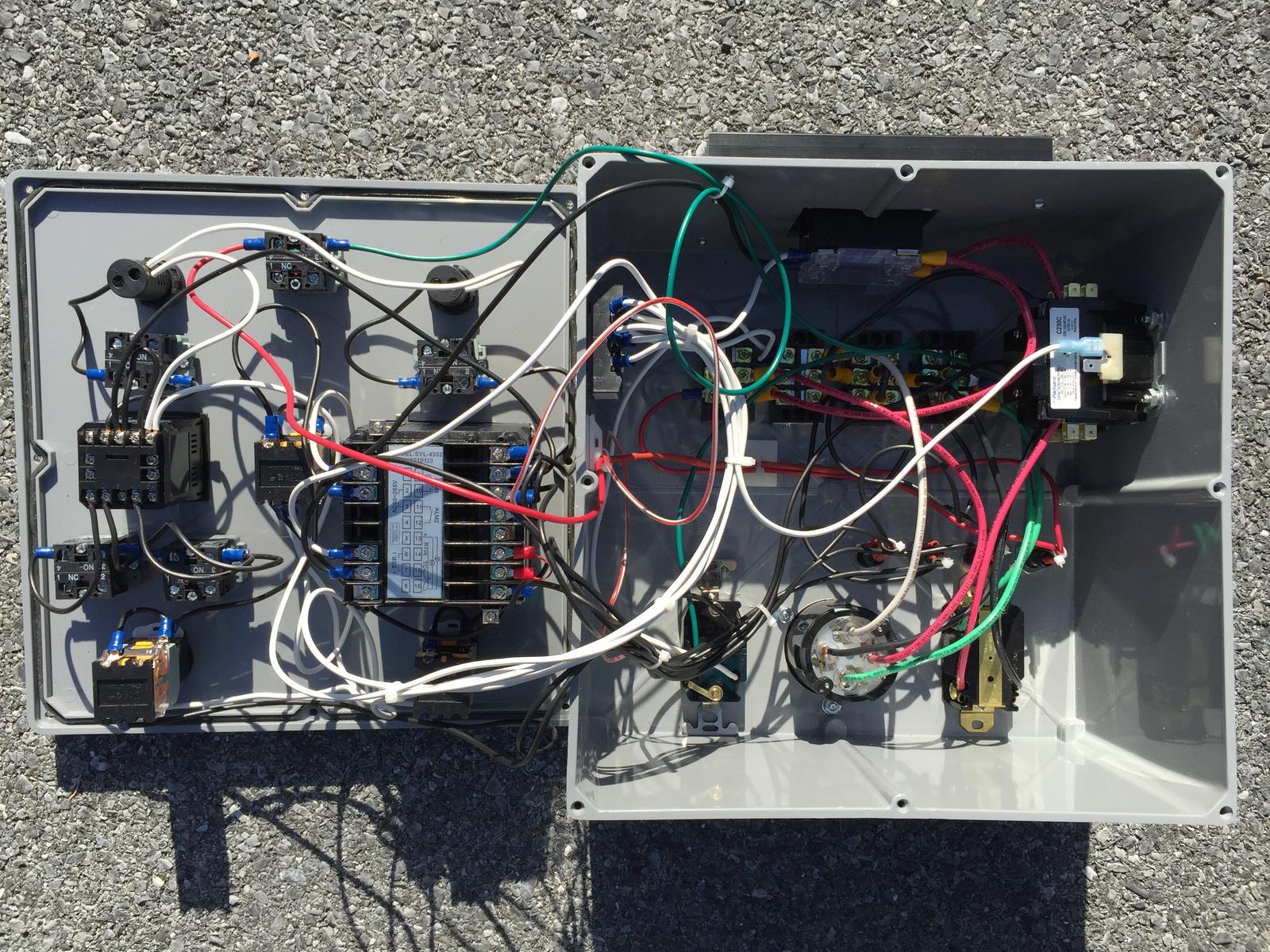

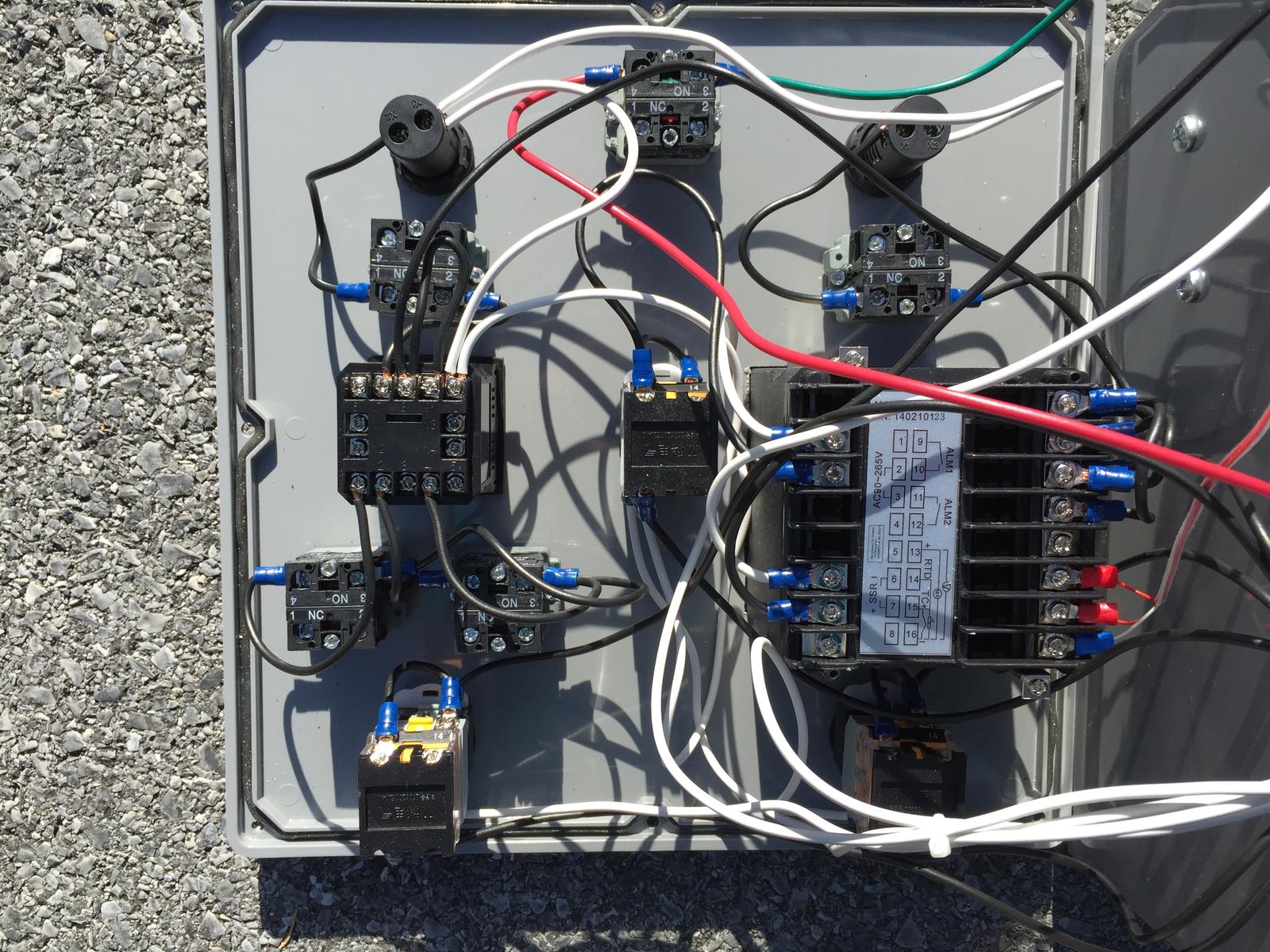

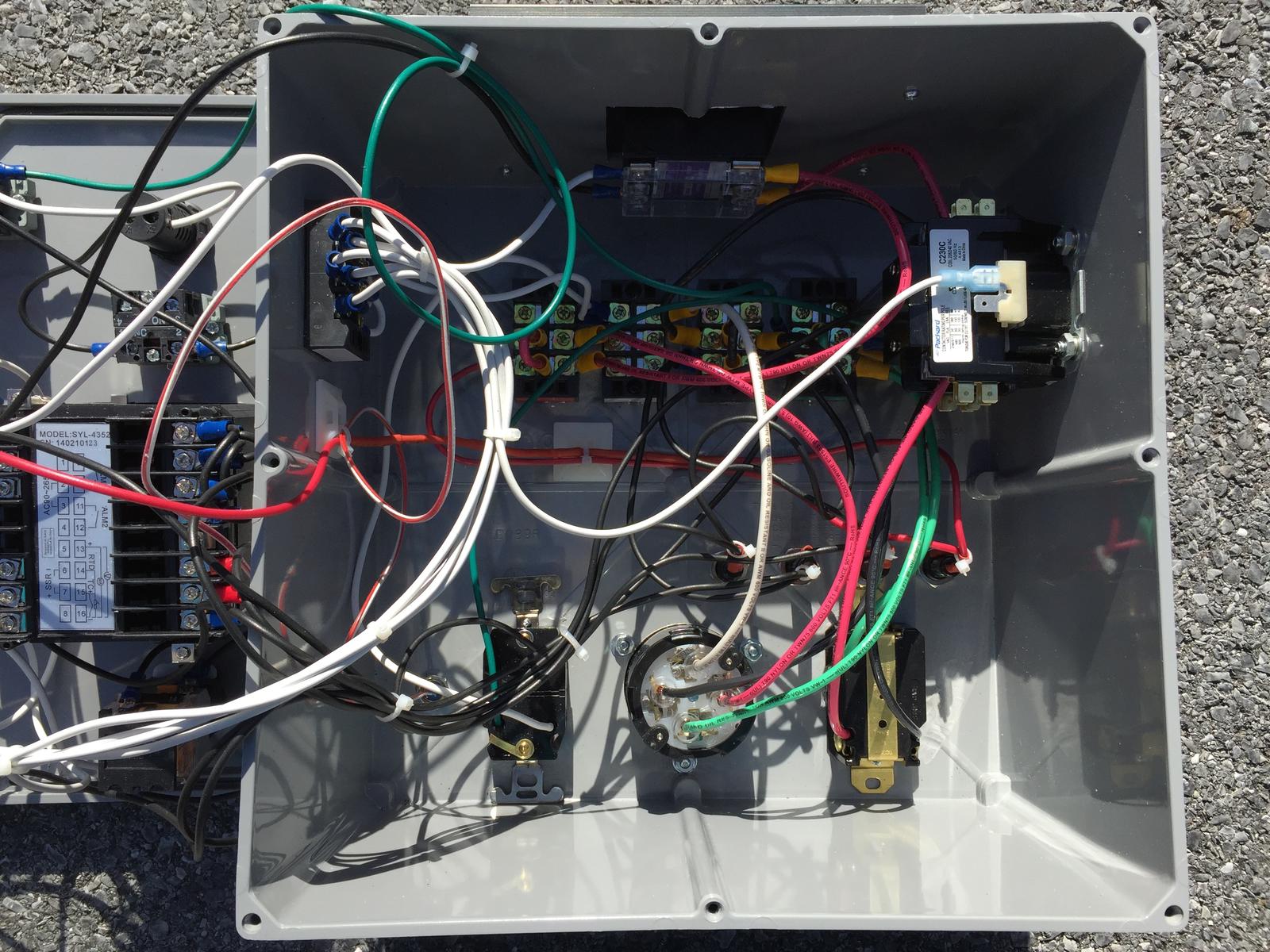

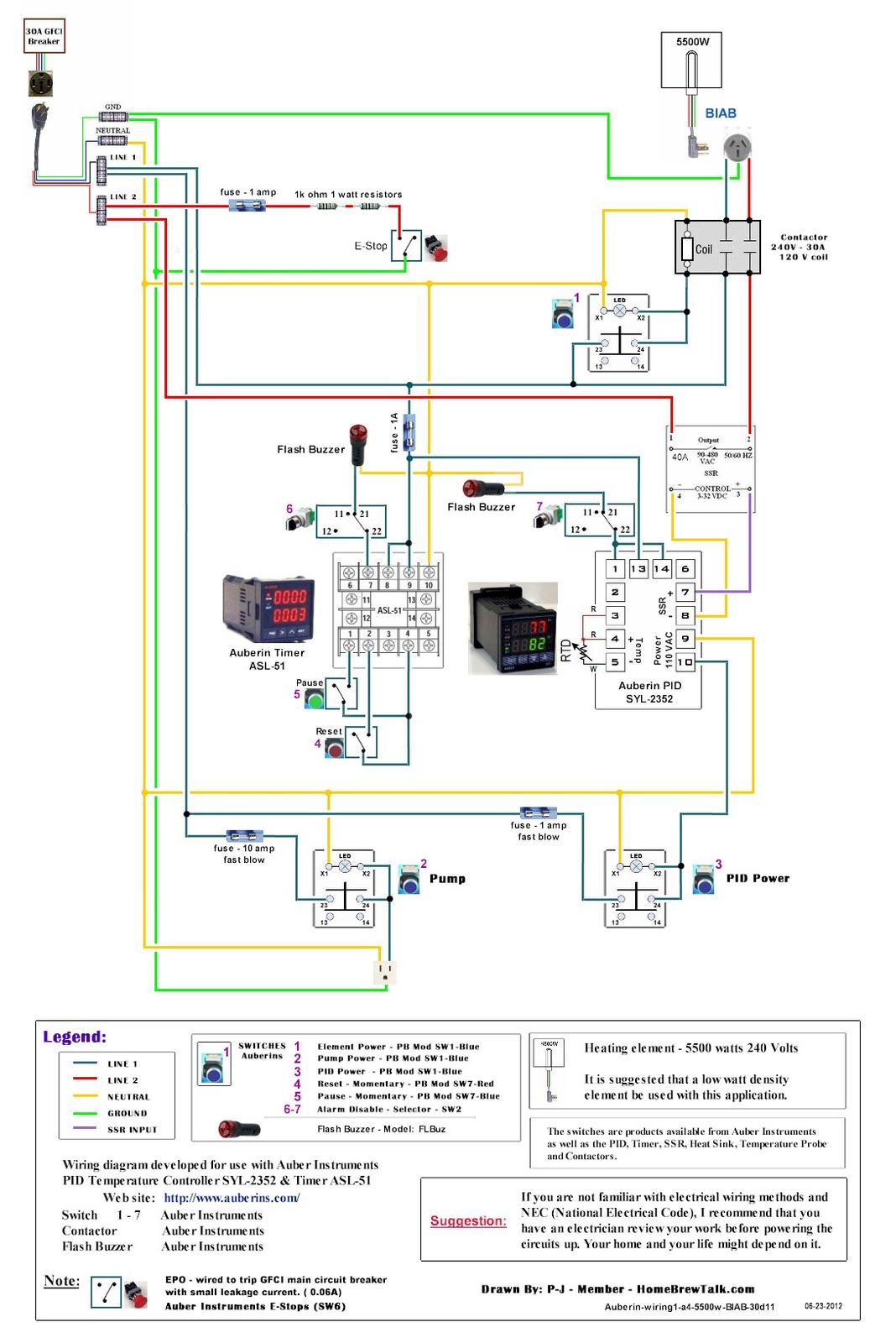

After having a 1/2 barrel, three vessel, gas fired, BCS controlled brew system and looking at the $3000 turn key German systems that undoubtedly would require factory service is something fails, I decided to build a Single Vessel Electric Brewing System that I can service and provides automation in a small package. These shots are from the first phase, the kettle build. Since working with a round kettle can be awkward, I built a cradle out of a spare 2 x 6 I had in the garage. Made hole cutting a lot less challenging. Also attached is my complete parts list and total cost. The control panel will be next and thanks to Aubiecat and PJ for all their great posts and diagrams.

View attachment Brew Kettle Part List.pdf

View attachment Brew Kettle Part List.pdf