iijakii

Well-Known Member

Those side cabinets are sweet. I vote a top, this isn't propane!

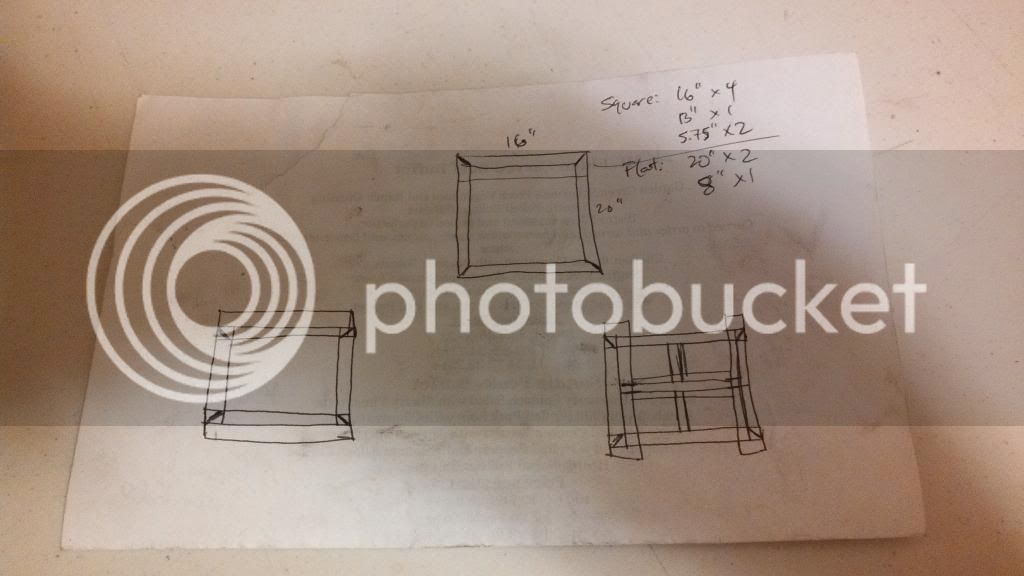

Here are some updated pictures:

I still haven't decided how to finish the stand. I was going to put some cross bars on the top to hold the kettles, but I was also considering putting a top on it. Just something thin like 12 gauge. Decisions, Decisions...

I got my hands on a prep table from the family restaurant and I LOVE having a solid top but I also hate it... I've spilled water and it has no where to go with a solid top, but it would keep stuff from spilling all over your cabinets... Its all personal preference.

Very nice work!! I wish I had the ability to weld, never done it...

I like the flat top, I'm planning the same for my BK, and HLT with a tippy dump mash tun based loosely off another thread on here on HBT.

I'm subscribed to see this one out! Keep building!

Sent from my iPhone using Home Brew

Do you plan on finishing the top in anyway? I will soon be building something similar for my setup as well as a work bench and cant decide what i want for the top. Stainless seems too expensive and I like your option of mild steel. Maybe give it a decent finish and then spray it with a clear coat of rustoleum?

Wow you must be an electronics engineer on the side to just come up with your own panel. The rest of us need to follow someones schematic so we dont burn something expensive down. Which is why I think I will go the gas route and just stick to manual with a couple of PIDs set up and incremently move up from there. Plus with gas your not restricted by where you plug in as you wont need 3 phase power to brew.

SCott-

That is what I ended up doing. Works fine.

I am working more bugs out with my BCS programming right now. Just moving some water around. Currently running the "mash."

I did have another BCS question: how do I associate a different temp probe with a different output? I have a temp probe in my BK but since I only have 2 heating element outputs and 2 pump outputs the BCS is associating the BK temp probe with pump 1. I can't figure out how to change that?

Go to edit process

process set up

page down to Miscellaneous State Properties

go to Alternate PID

you can change temp probe association to output scorce...

Enjoy

Enter your email address to join: