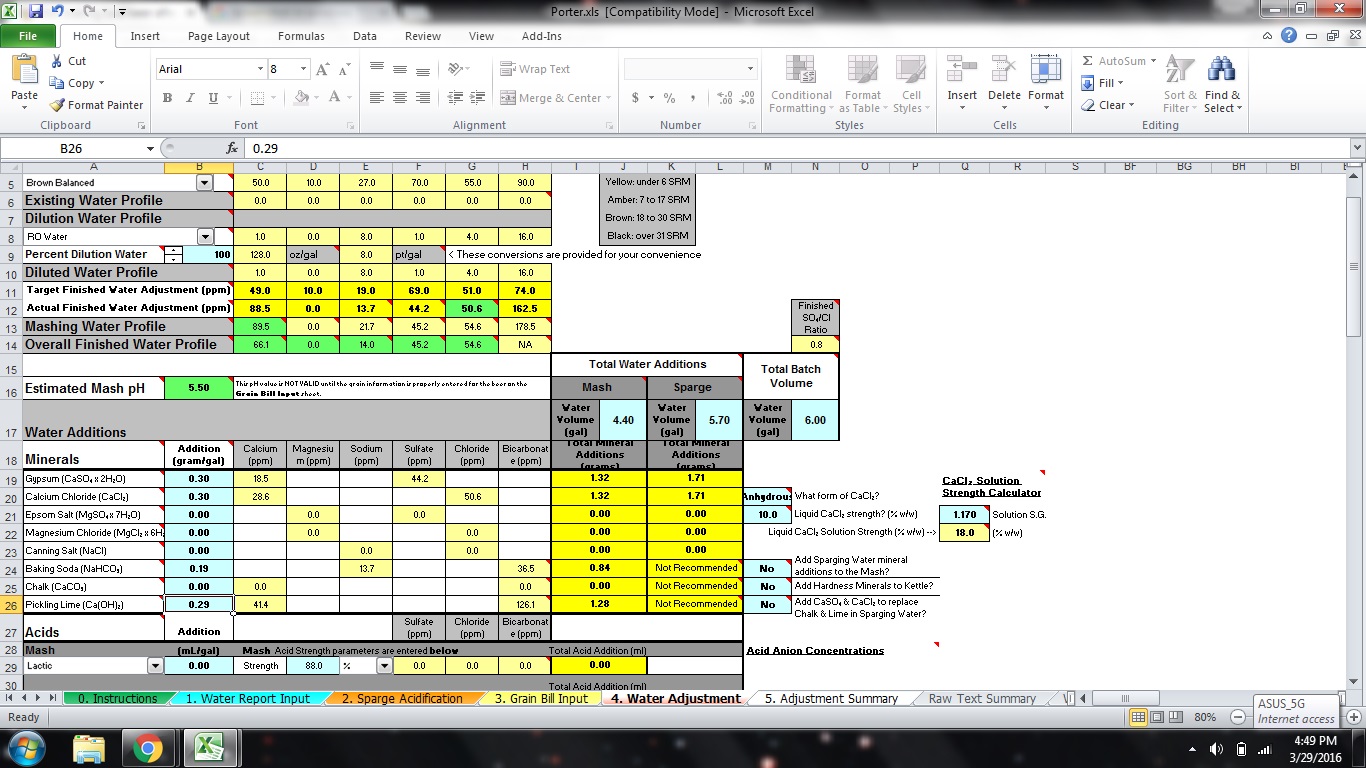

I'll see if I can explain my process in a fairly brief manner: I start off by heating up roughly 4-gallons of mash water in a stainless pot. In the past I've used bottled water, now I use R.O. with salt additions using BruN water. I taste the water after the additions and it tastes as good as any. I heat the water up to 170-ish degrees and dump it into my 10-gallon mash tun with a false bottom. I leave the water in there until it cools to around 165 degrees. Once I get this temperature, I add the grain. I mix it all up for a few minutes and then read the temperature. I'm usually around 152(depending on recipe). Within the hour of mashing, I stir it up every 20 minutes and take a temp reading. I typically lose 2 degrees within the hour. I then vorlauf around 3-4 quarts until the cloudiness is gone. Once the initial volume has drained into my keggle, I then batch sparge by adding in another 5 gallons of 168 degree water, stir and let sit for ten minutes. I again vorlauf until clear. This leaves me with around 7-gallons of wort. I heat the wort up on a natural gas burner until the hot break. I back down the flame until I get a rolling boil. I add hops according to schedule. I typically boil for 60 minutes unless I'm making a really light beer in which I'll do 90 minutes. With 5 minutes left in the boil, I'll add my copper wort chiller into the wort. While I'm boiling/cooling the wort, I clean and sanitize everything. Everything in the post boil process is saturated in StarSan; bucket, lid, air lock, scissors, yeast package, hydrometer, graduated cylinder, and stainless mesh strainer. This is when I usually rehydrate my dry yeast. If I'm using liquid, I make a starter 36-48 hours in advance. I cool the wort to around the intended fermentation temp (66 degrees for the last batch). I drain the wort into a bucket through the stainless mesh strainer. This seems to aerate the wort fairly well. I then add the yeast and close it up and add StarSan to the airlock. I place the bucket in my basement which is currently 62 degrees ambient. I have a thermometer on top of the bucket for ambient temperature and a "stick on" lcd thermometer for approximate wort temperature. I also use an infrared thermometer to check the bucket temperature. The "stick on" thermometer and the infrared are always within 1 degree of each other. Currently this temperature is 4 degrees higher than ambient at 66 degrees. I check it once a day and make sure there are no swings in temperature. My basement is fairly consistent so I never expect any. After the fourth or fifth day, I'll bring the bucket up a level (I live in a quad level house) where the wort temperature raises to around 68 degrees. I then leave it as is for 4-5 weeks, I don't use a secondary. When it's time to keg, I completely disassemble the keg and clean and sanitize. I rack the beer into the keg avoiding any splashing. I take F.G. reading and it usually is spot on. Once the keg is full, I attach Co2 and then purge for 10-15 seconds. I place the keg into my fridge at 10 PSI and let it sit for a week. I've also force carbonated with the same results. With my last batch, the off-flavor was present going into the keg. That's it in a nut shell. I've also replaced buckets, airlocks, hoses, valves and many other things. The one thing I haven't done yet is add O2 to the wort. I've had great beer made by others without it so I don't know if it's completely necessary. See any glaring faults in my technique? Thanks for reading!