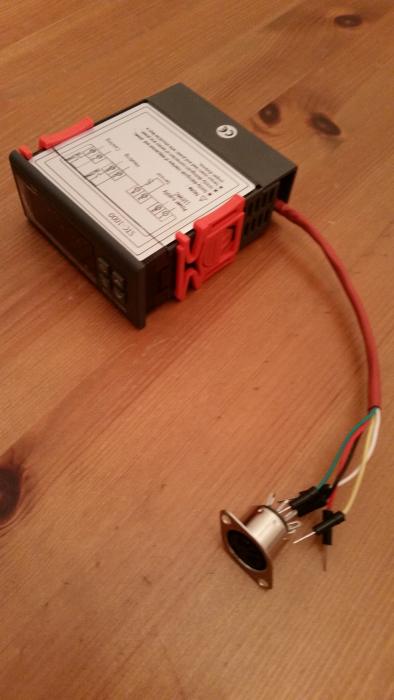

Holy fermentation controller batman!

Ok, I haven't really done much code wise or so this weekend, but I think it has been a pretty good one for the STC-1000+ project anyway. I think that using $5 equipment for a programmer is pretty cool, when the intended programmer (PIC kit 2) costs probably 10-15 times more.

And today I made another discovery. I noticed that just next to the screw terminal for the thermistor, there is an unused solder pad.

It just 'happens' to be routed to ISCPCLK, the only pin not used in normal conditions (i.e. when not flashing). In the picture you can see that there even are pads for an SMD resistor and SMD capacitor (R3 and C3), same as for the NTC input (R2 and C2, to the right in the pic, but kind of unreadable...). And yes, RA1 (the generic pin that ICSPCLK is on) also functions as A/D.

It is "almost" as someone designed this board to be able to handle

TWO thermistor inputs. :rockin:

Why is this awesome? Well, it seems that with a little bit of soldering, and some cheap SMD components off ebay and some of blood, sweat and code (at least on my part), we could have an extra temperature input. This could be used for things like measuring fridge temperature, making sure it does not shoot off too far before beer temp catches up (limit over/under-shoot). Or when I get around to finishing my mash firmware, you could measure mash temp AND output temp from RIMS.

Heck, if you are able to code yourself, you could use it for anything. Not only an input. SSR output? Float switch?

I am gonna try to enable a secondary temp reading. Personally I think it would be cool (pun intended) to be able to set limits on fridge temp (like the hysteresis).

As best I know now, what you would need is a new 3 pole screw terminal (5mm pitch) to replace the 2 pole. And an SMD resistor and capacitor (probably 0603 form factor) and an extra NTC thermistor (B3435). The resistor is 10K with as good accuracy as possible (1%?, this is part of the voltage divider with the NTC). The capacitor should not be as critical, from what I could find with google 10-100uF is prolly in the right range.

Cheers!

No alarm, no problems detecting my controller. The solder pads looked good enough originally, but who knows?

No alarm, no problems detecting my controller. The solder pads looked good enough originally, but who knows?