augiedoggy

Well-Known Member

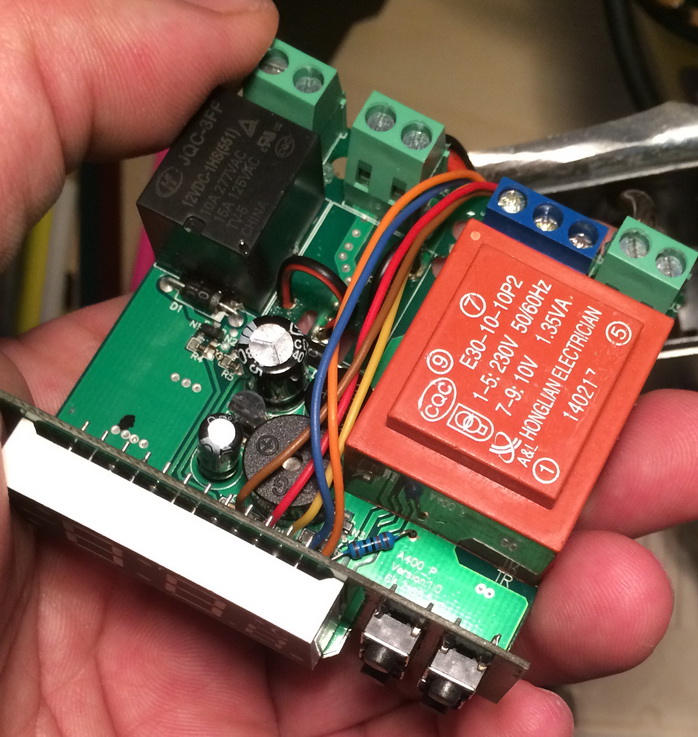

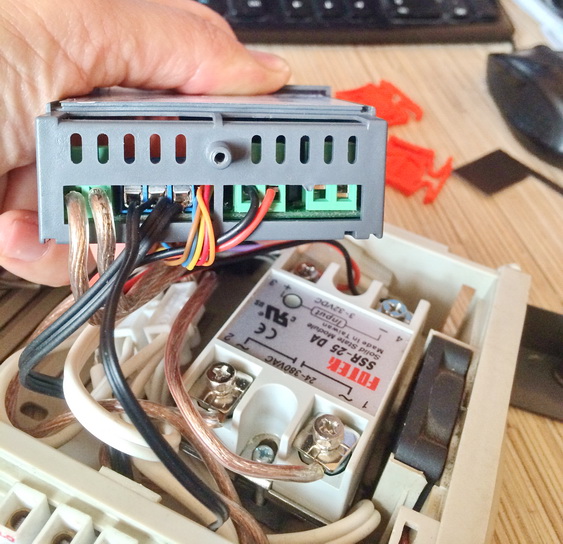

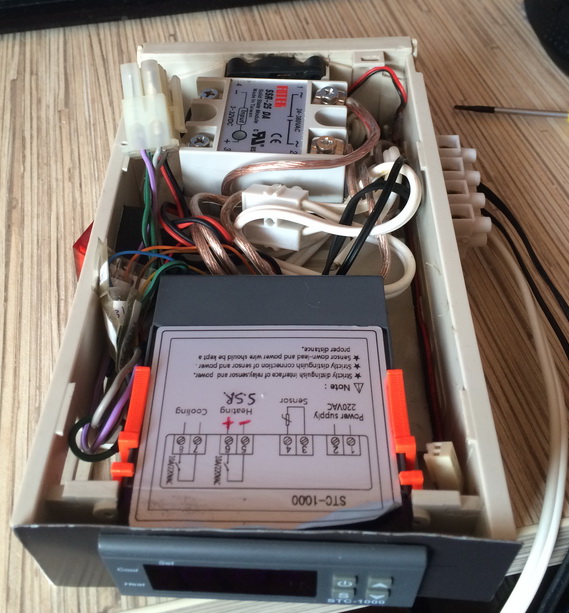

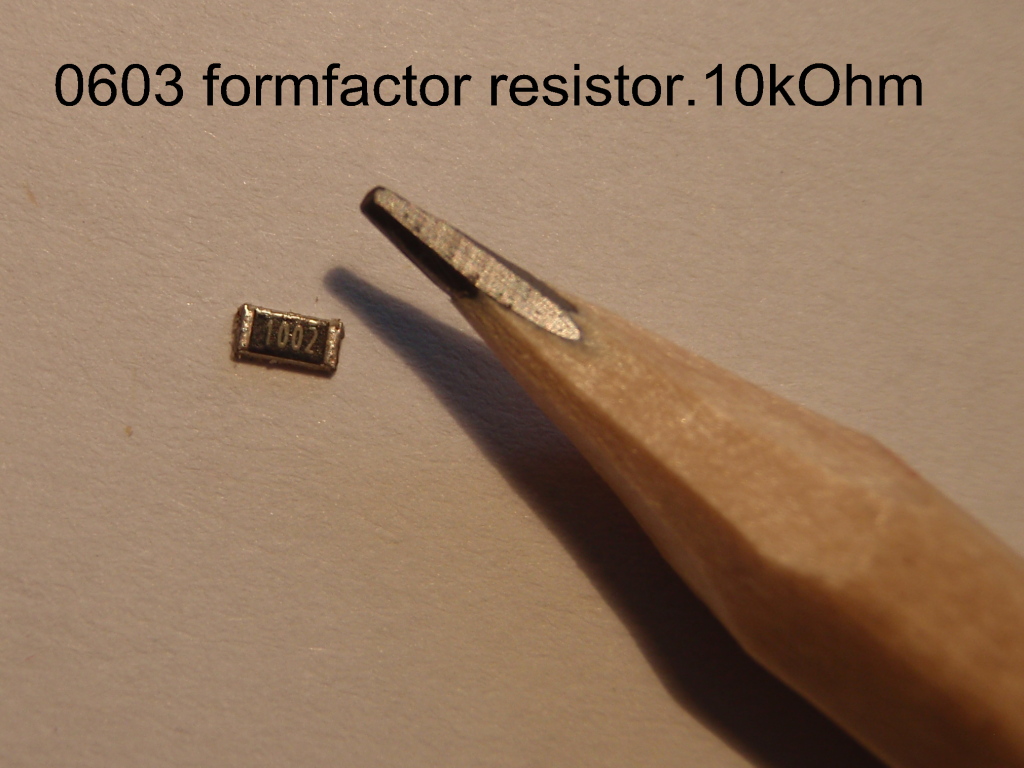

I got my unprogrammed stc 1000 from blackbox today... It took all of 30 minutes to pull it apart and flash with my $7 uno clone (DCcdinino uno) thanks to the instructional videos.... still debating on whether I need the second probe or not.... I dont believe I will for my conical with the chiller/ heating pad setup since my temp probe reads from the center of the liquid inside... or would it still be useful?