ClaudiusB

Well-Known Member

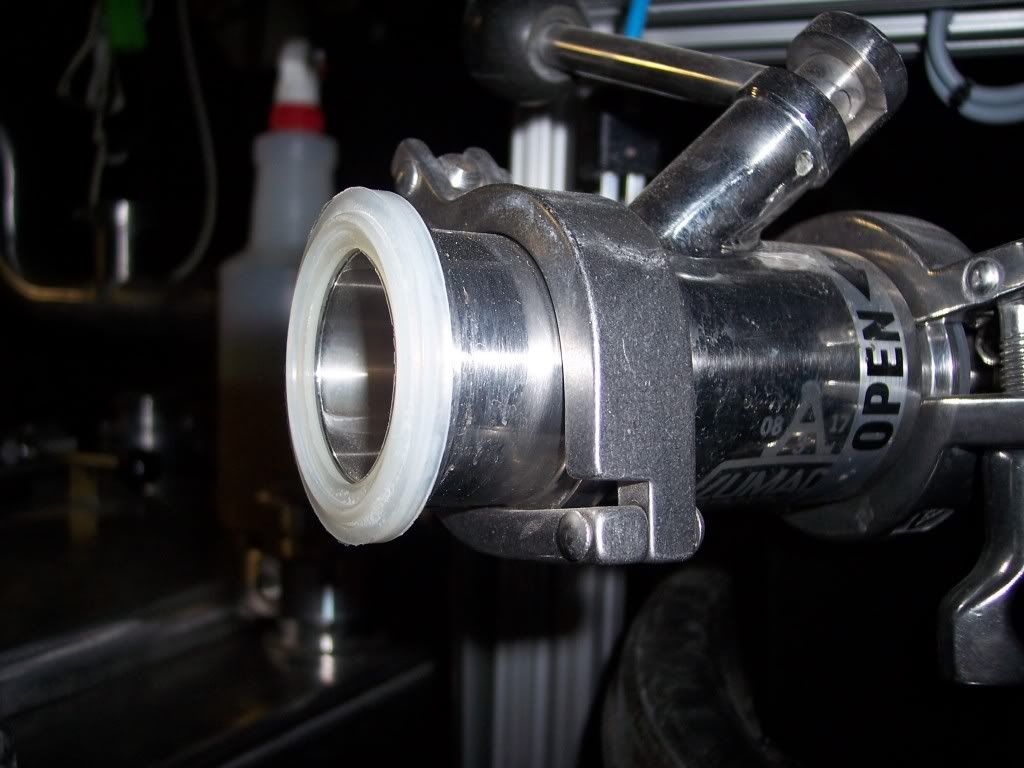

You can solve the problem by using the correct gasket.For me, camlocks are easier to use. I always end up dropping the gasket whenever I used tri-clovers. So I have to sanitize it all over again.

Stay in place seals.

Bobby_M as always a great video and good info.

Cheers,

ClaudiusB

So stoked.

So stoked.