I've been using these for a few years now and absolutely love them so I decided to make some and see if anyone is interested in buying them. Let me know what you all think. I have one available now and more on the way soon if people are interested in them.

$120 plus shipping

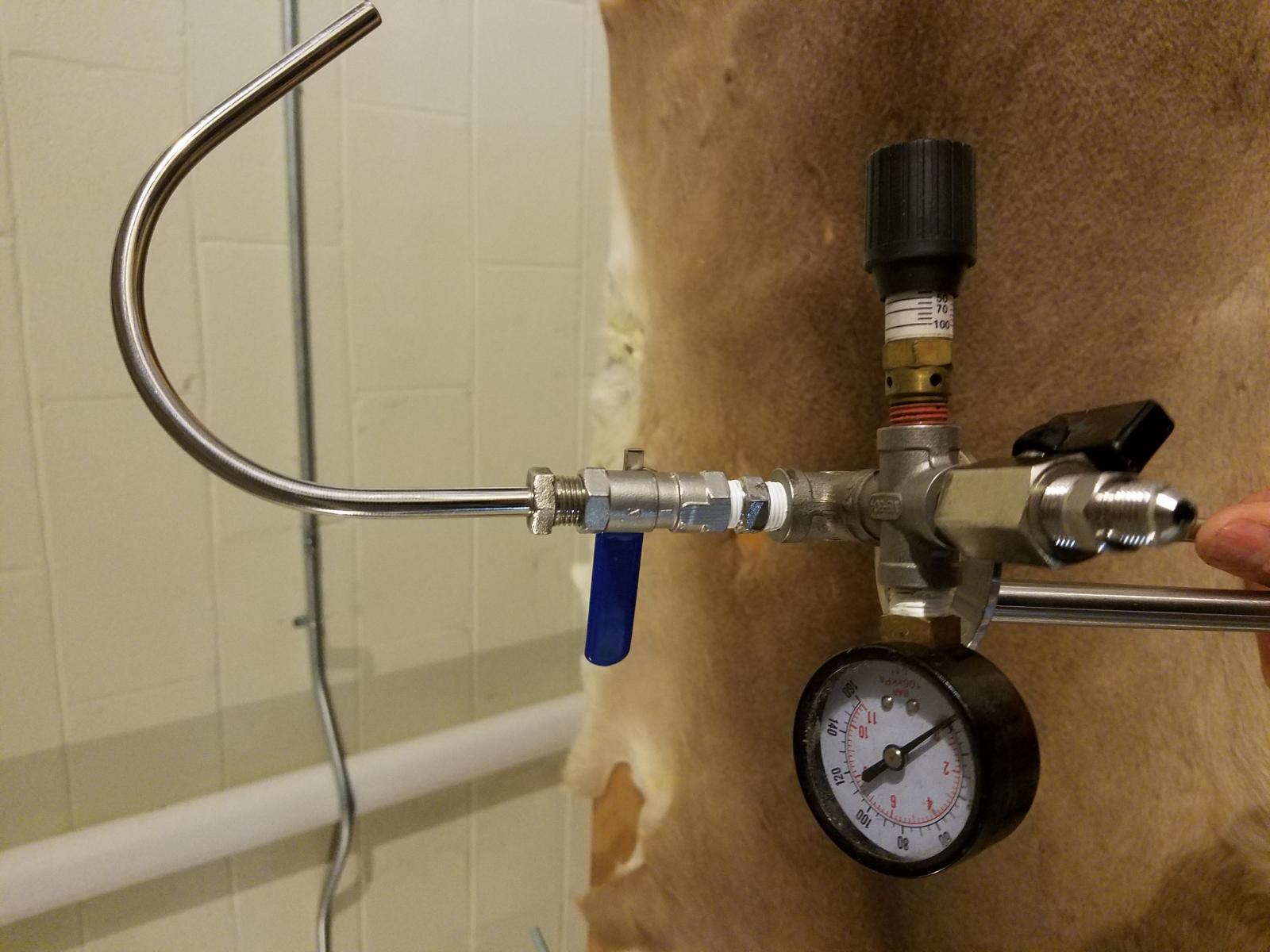

It allows a home brewer to use a Sankey keg as a fermenter much more efficiently. Unlike almost all home brew conical fermenter available today, a keg will hold much more pressure allowing the beer to be naturally carbonated. This is the same technique a commercial brewery uses to carbonate their beer and means no more force carbonation, and no more waiting. The beer is carbonated and ready to drink the moment you transfer it. Just close the blow off when you are around 5 gravity points from your final gravity and let the yeast do the rest. You can also draw samples to taste and to check the gravity. The kit includes a low pressure gauge (15psi) and an adjustable pressure relief valve so you can dial in the exact desired carbonation level. The dip tube allows for pressurized transfers, and because of if it's design, the beer doesn't touch any parts except the dip tube and the ball valve which makes for a sanitary, easy to clean product. Just attach your hose barb or tail piece fitting and transfer to your serving keg or bottle with a counter pressure filler.

For those of you who already have a conical fermenter this device lets you use a Sankey keg as a bright tank or a secondary fermenter. This will allow you to brew more often by freeing up your fermenter for new batches.

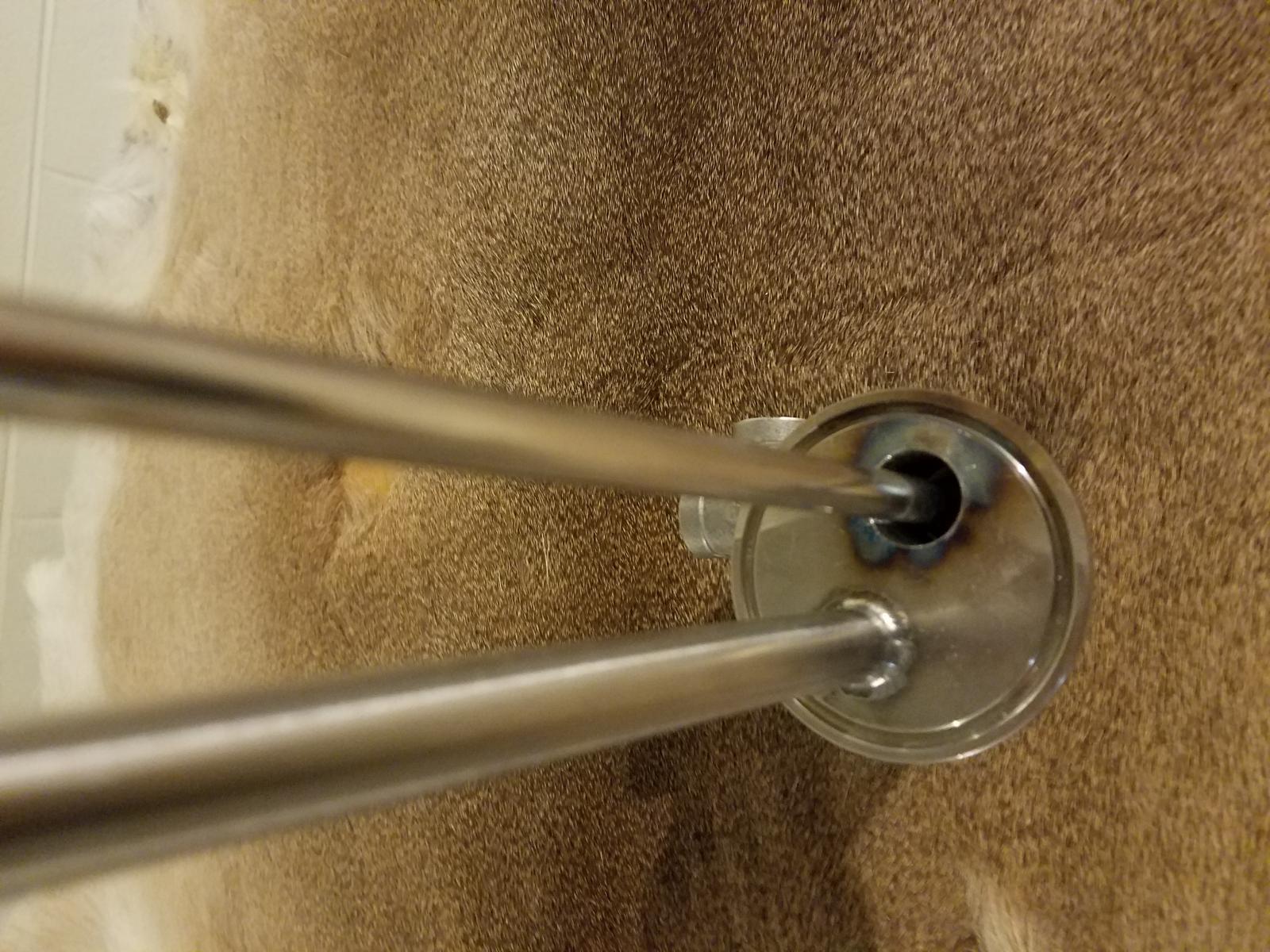

All components are made of food grade stainless steel and the welds have been back purged with Argon to ensure a clean weld on the inside. All threads are ¼ NPT. Overall length is approximately 31”, width 7” and depth 7”. Thermowell is 17.5” long x ½ OD and dip tube is 20.5” x 5/16 OD.

These measurements are for ½ barrel (16 gal), the newer tall style ¼ barrel (8 gal) and 5 gal kegs. I can make one for the old short style 8 gallon kegs on request,

Kit includes, 2” Tri-Clover end cap with welded fittings and thermowell, 2 “ Tri-Clover clamp, silicone o-ring gasket, dip tube, 15 psi pressure gauge, adjustable pressure relief valve, 2 stainless steel mini ball valves, sampling tube and instructions.

https://scontent-atl3-1.xx.fbcdn.net/hphotos-xap1/v/t1.0-

9/261381_215843965421278_5366762640425387234_n.jpg?

oh=4ed269b4e1e2d1c1c92f167f12eab44e&oe=57066634

$120 plus shipping

It allows a home brewer to use a Sankey keg as a fermenter much more efficiently. Unlike almost all home brew conical fermenter available today, a keg will hold much more pressure allowing the beer to be naturally carbonated. This is the same technique a commercial brewery uses to carbonate their beer and means no more force carbonation, and no more waiting. The beer is carbonated and ready to drink the moment you transfer it. Just close the blow off when you are around 5 gravity points from your final gravity and let the yeast do the rest. You can also draw samples to taste and to check the gravity. The kit includes a low pressure gauge (15psi) and an adjustable pressure relief valve so you can dial in the exact desired carbonation level. The dip tube allows for pressurized transfers, and because of if it's design, the beer doesn't touch any parts except the dip tube and the ball valve which makes for a sanitary, easy to clean product. Just attach your hose barb or tail piece fitting and transfer to your serving keg or bottle with a counter pressure filler.

For those of you who already have a conical fermenter this device lets you use a Sankey keg as a bright tank or a secondary fermenter. This will allow you to brew more often by freeing up your fermenter for new batches.

All components are made of food grade stainless steel and the welds have been back purged with Argon to ensure a clean weld on the inside. All threads are ¼ NPT. Overall length is approximately 31”, width 7” and depth 7”. Thermowell is 17.5” long x ½ OD and dip tube is 20.5” x 5/16 OD.

These measurements are for ½ barrel (16 gal), the newer tall style ¼ barrel (8 gal) and 5 gal kegs. I can make one for the old short style 8 gallon kegs on request,

Kit includes, 2” Tri-Clover end cap with welded fittings and thermowell, 2 “ Tri-Clover clamp, silicone o-ring gasket, dip tube, 15 psi pressure gauge, adjustable pressure relief valve, 2 stainless steel mini ball valves, sampling tube and instructions.

https://scontent-atl3-1.xx.fbcdn.net/hphotos-xap1/v/t1.0-

9/261381_215843965421278_5366762640425387234_n.jpg?

oh=4ed269b4e1e2d1c1c92f167f12eab44e&oe=57066634